Basic Info.

Model NO.

WT-BS-T150

Trademark

MEYWADA

Origin

China

HS Code

854330

Production Capacity

7000kg/Day

Product Description

Specification of Copper Busbar Tin Plating Machine

1. Brief Introduction:

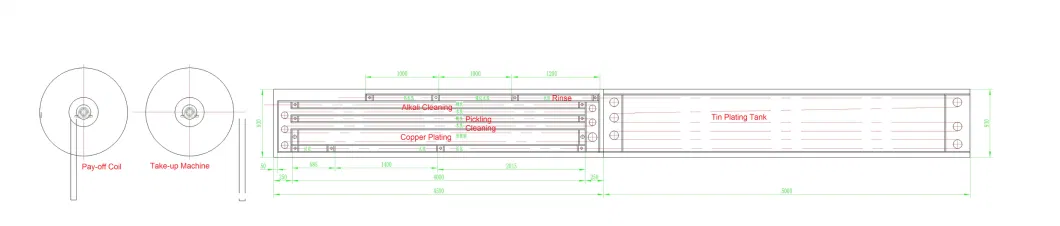

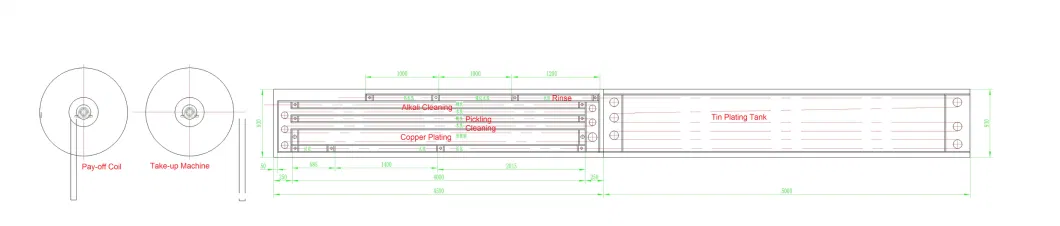

1.1. Strip Through type: Straight type, from Left to Right;

1.2. Coil Width: Max. 150mm

1.3. Brass strip thickness: 0.5mm ~ 15mm

1.4. Speed: 0 ~ 70m/min

1.5. Tin layer thickness: 0 ~ 10um

1.6. Processing: Pay-off Machine with Damping brake → Electrolytic Alkali & Staged Rinse → Pickling Cleaning & Staged Rinse → Tin Plating → Staged Rinse → Deactivation Processing → Drying by Electric Heating → Torque Motor Take-up Machine

1.1. Strip Through type: Straight type, from Left to Right;

1.2. Coil Width: Max. 150mm

1.3. Brass strip thickness: 0.5mm ~ 15mm

1.4. Speed: 0 ~ 70m/min

1.5. Tin layer thickness: 0 ~ 10um

1.6. Processing: Pay-off Machine with Damping brake → Electrolytic Alkali & Staged Rinse → Pickling Cleaning & Staged Rinse → Tin Plating → Staged Rinse → Deactivation Processing → Drying by Electric Heating → Torque Motor Take-up Machine

1.8. H.F. Rectifier:

1.10: Colour of Machine: Olive PP plate,

Pay-off & Take-up Machine: Blue

Electrolysis Alkali Cleaning: 1000A/8V, 1unit

Electrolytic Pickling Cleaning: 1000A/8V, 1unit

Tin Plating Tank: 3000A/8V, 1unit

1.9. Machine Structure: Made by S304 pipe welding & Polished1.10: Colour of Machine: Olive PP plate,

Pay-off & Take-up Machine: Blue