- Overview

- Product Description

- Detailed Photos

- Company Profile

Basic Info.

Product Description

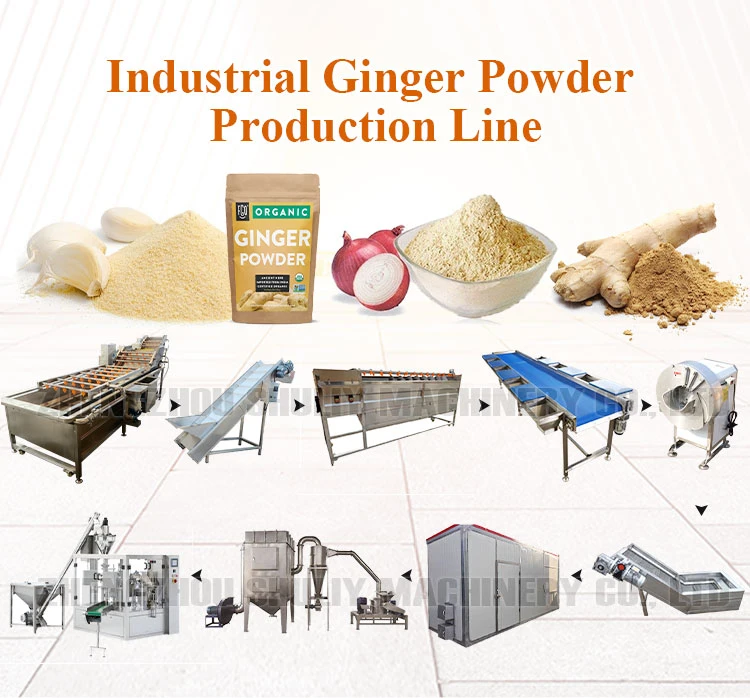

Ginger powder production line: automatic ginger powder production line is used to make ginger powder or turmeric powder.

As a kind of medicinal and medicinal seasoning, ginger has a spicy and aromatic flavor. Ginger powder made of ginger can be used as a food additive for seasoning, pickling, soup, blending ginger tea, and it is quicker and more convenient to use. Processing ginger powder with ginger can significantly increase the added value of ginger in the ginger field, and reduce the loss of ginger and the cost of storage and transportation.

1.Cleaning and peeling machine: The whole machine is made of stainless steel, and the friction principle between the brush and the brush is adopted to achieve the effect of cleaning or peeling. Customers can choose from wavy or straight type; soft and hard rollers and special custom rollers to meet different needs.

2.Ginger slicer: suitable for cutting a variety of roots, fruits and vegetables. The effect of cutting out the machine is thin and even, and the appearance is beautiful.

3.Blanching machine: Rinse and clean the cut ginger slices to prevent browning after slicing to make the ginger color deeper and reduce the loss of active ingredients in the drying process.

4. Continuous fruit and vegetable air dryer drive adopts speed-regulating motor, which makes the air-drying effect of the product adjustable and the mesh belt runs smoothly. This machine is made of high quality 304 stainless steel except for standard parts such as fans and motors. Suitable for flow operation, improve the degree of automation of the enterprise, and effectively protect the color and quality of the material itself.

5. Dryer: The small cart is a mobile dryer that can hold multiple trays. Suitable for a wide range of materials.

6. Grinding machine: The dried ginger pieces are pulverized.

7. Packaging machine: The powder packaging machine mainly packs powdery materials, and the whole process is fully automated.