- Overview

- Packaging & Shipping

Basic Info.

Product Description

Product Description

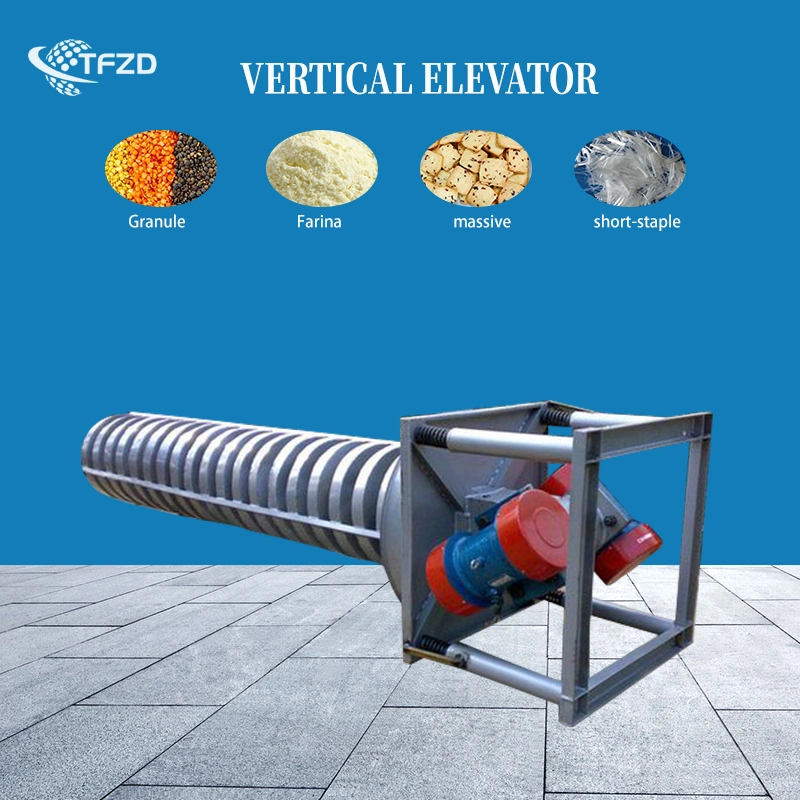

Grain Vertical Vibration Conveyor Corn Cooling Spiral Elevator

ZL Bucket Conveyor Machine is one of the most efficient ways to elevate bulk materials vertically. It consists of a series of buckets attached to a belt or chain with pulleys or sprockets located at the top and bottom of the unit. The buckets are located in a casing or housing to contain the material. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. We manufactures a wide variety of bucket conveyor machine based on the characteristics of the bulk material and the process requirements.

Product classification: conveying equipment series

ZL series spiral vibration vertical elevator uses the vibration motor as the vibration source and uses the combined amplitude of two vibration motors to transport materials up the spiral conveyor.

Technical Characteristics

1. Small floor area, simple and reasonable structure.

2. Low power consumption, no noise, and convenient maintenance.

3. Enclosed lifting prevents dust and harmful gas from polluting the working environment.

Working Principle

Zl series spiral vibration vertical elevator is composed of a lifting slot, vibration motor, damping system, and base. This series of hoists use vibration motors as the vibration source, and two vibration motors of the same model fixed on the lifting slot are installed at an intersection angle of the centerline and rotate in the opposite direction in a self-synchronous manner. When the eccentric block carried by the vibration motor rotates, the components of the centrifugal force generated at each instant position move back and forth along the throwing direction, making the whole body supported on the shock absorber vibrate constantly, The material can be thrown up at the same time in the lift chute. After falling into the feed chute, the material starts to be thrown up. At this time, the material can fully contact the air and also play a role in heat dissipation and cooling. The elevator can vertically transport powdery, blocky, and short fibrous solid materials (except those with viscosity and easy caking), and also can dry and cool materials. Special design can be carried out according to user needs.

Technical Parameter

Applicable industries

Chemical industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, wastewater recycling, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid, Chinese and Western medicine granules, etc.

Environmental protection: garbage, human and animal excrement, urine, waste oil, food wastewater, wastewater processing, etc.

After you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send the customer the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent the customer from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself.

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee the quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixers, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided many screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.