Basic Info.

Model NO.

CGL001

Energy Sources

Water, Electricity, Gas

Strip Thickness

0.2-2.5mm

Strip Width

500mm-1500mm (Max)

Warranty Period

1year

Transport Package

Standard Seaworthy Package

Specification

steel

Origin

China

HS Code

8479819000

Production Capacity

12set/Y

Product Description

1500mm Continuous Galvanizing Line

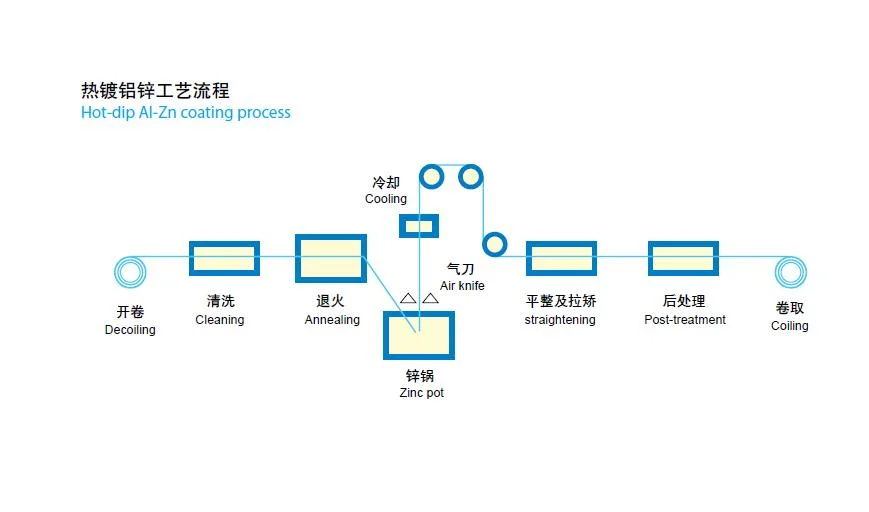

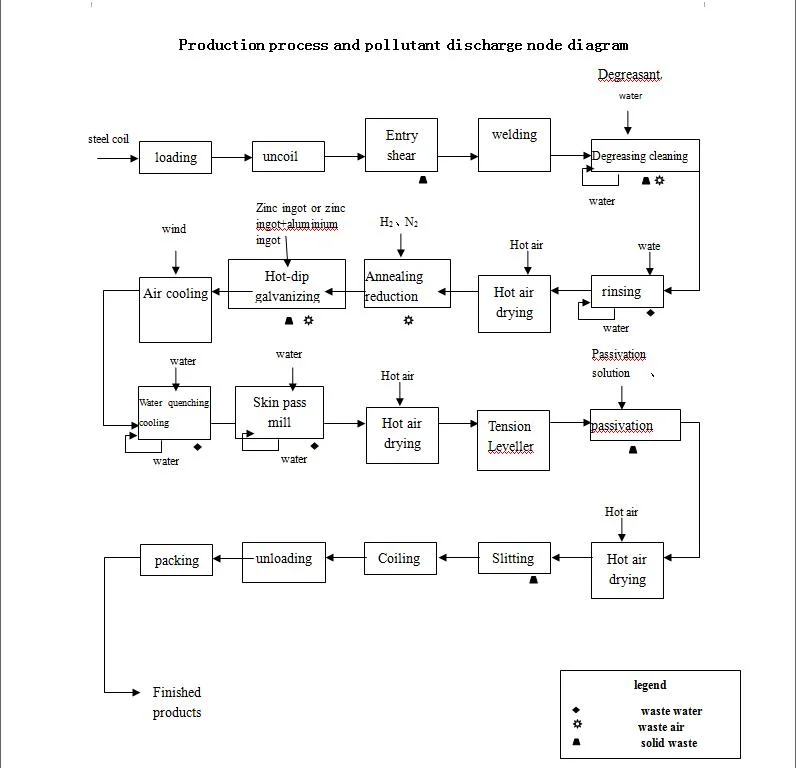

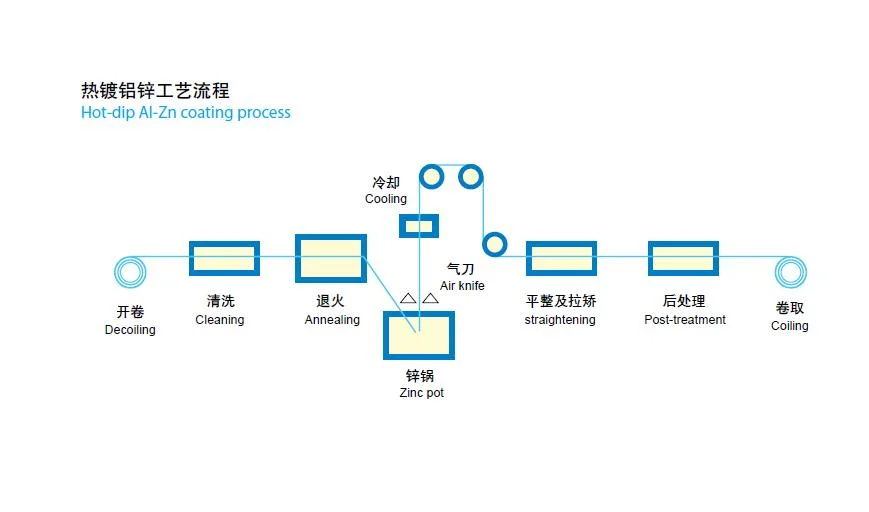

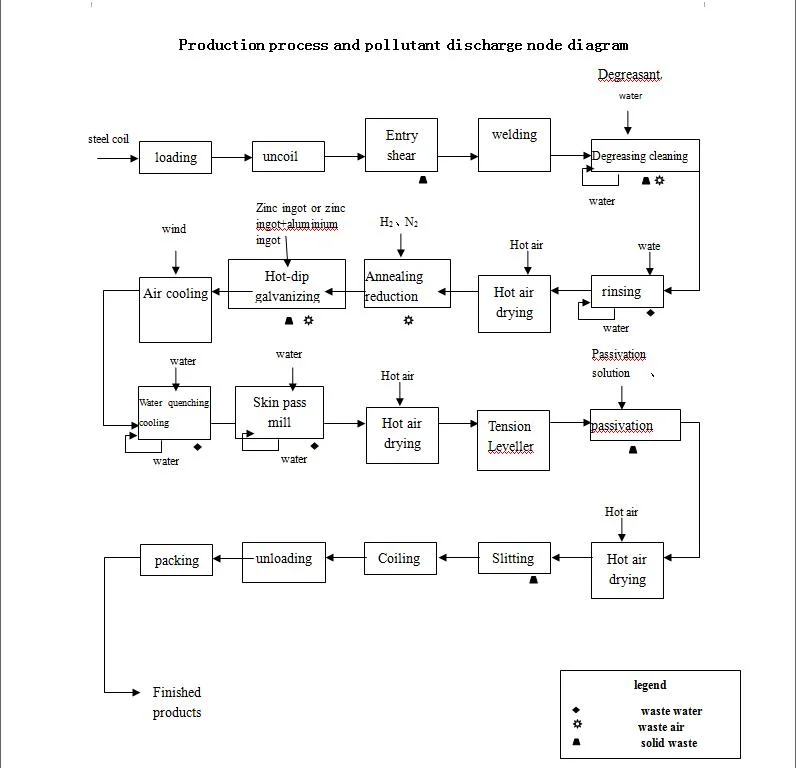

The hot dip galvanized steel sheet to be cleaned will be immersed in the dissolved zinc pot after reduction annealing to make the surface adhere to a layer of zinc or zinc-aluminum alloy thin steel sheet to improve the corrosion resistance of the steel sheet.Hot dip galvanized steel is mainly used in construction, home appliances, automobiles, machinery, electronics, light industry and other industries.

Line Main Properties :

1. Line Type : horizontal, vertical, combination of vertical and horizontal

2. Specification / Thickness : cold rolled strip / min. 0.12mm, max. 2.5mm

hot rolled strip / min. 1.5mm, max. 5mm

Width : min. 550mm, max. 1500mm

3. Speed in Process Section: max. 200m/min (240m/min for GL)

4. Continuous Annealing Furnace:

Furnace Type: horizontal, vertical, combination of vertical and horizontal (L type) Heating Method: Gas non-oxidation heating (NOF), Gas radiant tube heating (RTF), Electric radiant tube and electric resistance tape heating Cooling Method: Shielding gas regular air jet cooling, rich hydrogen high speed air jet cooling

5. Zinc pot: jet flow ceramic induction zinc pot (GL line with pre-melting pot)

6. Air knife: single injection advanced air knife, multi-cavity air knife

7. Skin Pass Mill: 300T-800T, 4-roll wet skin pass

8. Energy saving method: high efficiency radiant tube combustion air heat exchanger, fume duct combustion air heat exchanger, fume duct hot air and hot water heat exchanger, hot shielding gas recycle injection pre- heating strip, fume heat radiant before non-oxidation heating pre-heating strip, light fiber furnace lining

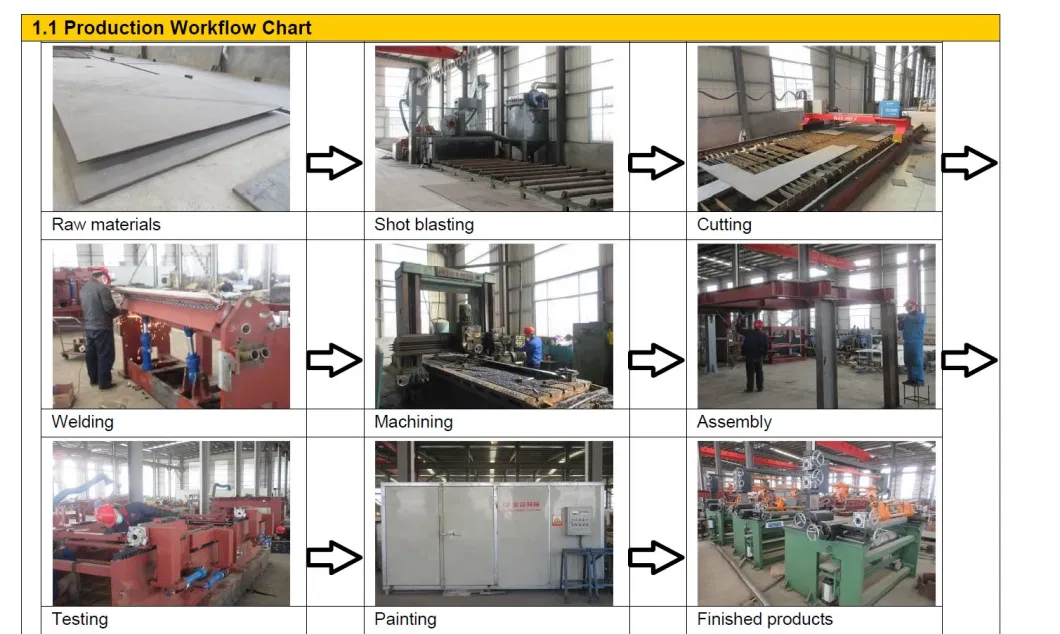

1. We are the leading manufacturer of metal coating machines in China, and we can give you the best price. We warmly welcome you to visit our factory at any time.

2. We have professional design engineers who can design and customize production lines according to your requirements.

3. Professional installation, good after-sales service and rich installation experience.

The hot dip galvanized steel sheet to be cleaned will be immersed in the dissolved zinc pot after reduction annealing to make the surface adhere to a layer of zinc or zinc-aluminum alloy thin steel sheet to improve the corrosion resistance of the steel sheet.Hot dip galvanized steel is mainly used in construction, home appliances, automobiles, machinery, electronics, light industry and other industries.

Line Main Properties :

1. Line Type : horizontal, vertical, combination of vertical and horizontal

2. Specification / Thickness : cold rolled strip / min. 0.12mm, max. 2.5mm

hot rolled strip / min. 1.5mm, max. 5mm

Width : min. 550mm, max. 1500mm

3. Speed in Process Section: max. 200m/min (240m/min for GL)

4. Continuous Annealing Furnace:

Furnace Type: horizontal, vertical, combination of vertical and horizontal (L type) Heating Method: Gas non-oxidation heating (NOF), Gas radiant tube heating (RTF), Electric radiant tube and electric resistance tape heating Cooling Method: Shielding gas regular air jet cooling, rich hydrogen high speed air jet cooling

5. Zinc pot: jet flow ceramic induction zinc pot (GL line with pre-melting pot)

6. Air knife: single injection advanced air knife, multi-cavity air knife

7. Skin Pass Mill: 300T-800T, 4-roll wet skin pass

8. Energy saving method: high efficiency radiant tube combustion air heat exchanger, fume duct combustion air heat exchanger, fume duct hot air and hot water heat exchanger, hot shielding gas recycle injection pre- heating strip, fume heat radiant before non-oxidation heating pre-heating strip, light fiber furnace lining

| Product Name | hot dip galvanizing line |

| Material | steel |

| Energy sources | water, electricity, Nature gas |

| Strip thickness | 0.2-2.5mm |

| Strip width | 1000-1500mm (max) |

| Weight | 700--800T |

| Size | 220m*18m*30m |

| Customized | Yes |

| Warranty period | 1year |

2. We have professional design engineers who can design and customize production lines according to your requirements.

3. Professional installation, good after-sales service and rich installation experience.