- Overview

- Product Specification

- Details Images

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Product Description

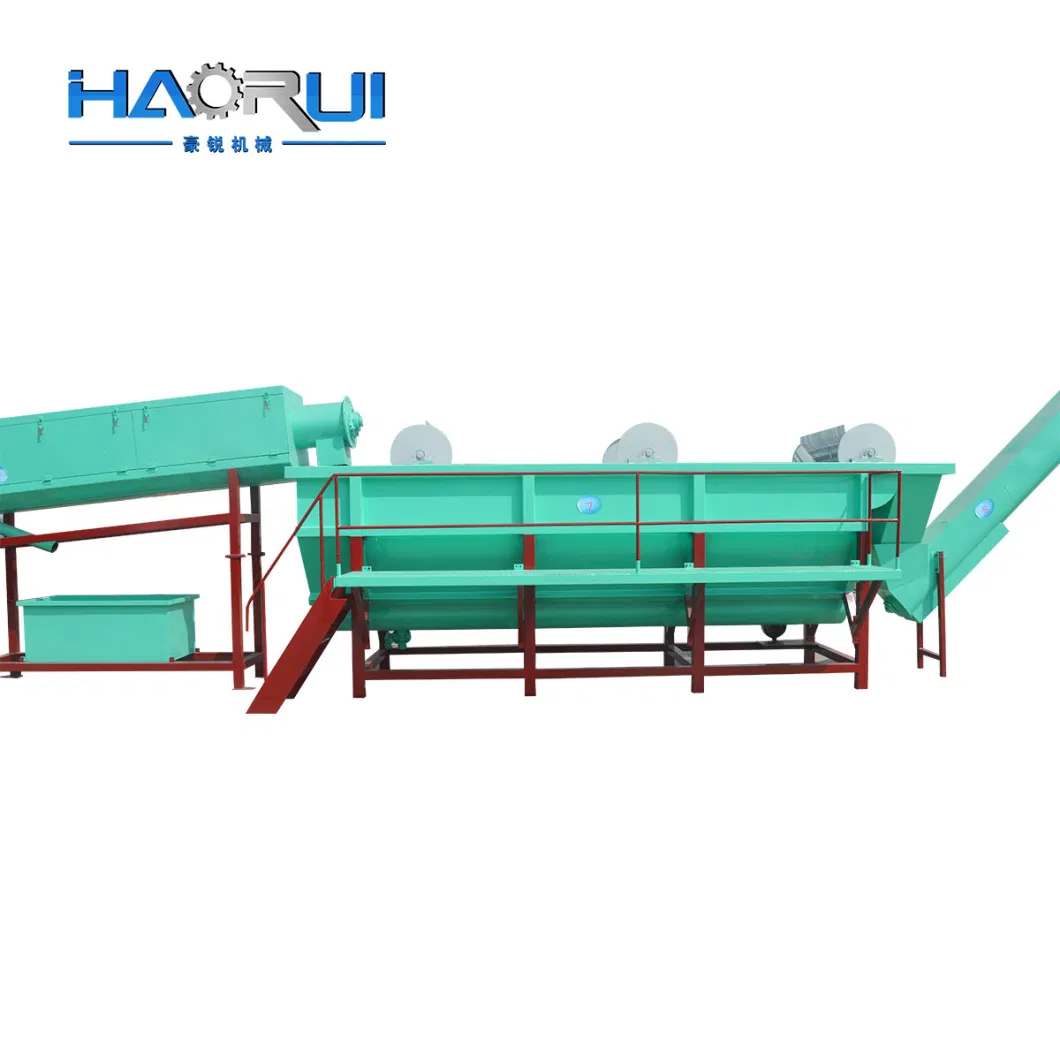

Make sure the bottle pieces are clean

The whole line comes out as clean bottles

Product Specification

| Model | Motor Power |

| packing size | Material | |

| 400type | 4kw | 500~2000kg/h | 4.5m(L)*1.1m(W)*1.1m(H) | Carbon steel | |

| 550type | 4kw | 2000~3000kg/h | 6m(L)*1.4m(W)*2m(H) | Carbon steel |

Different materials are different discharge ports

Cleaner cleaning

- Motor Power: 4KW/grade 4

- Roller wheel motor power: 2.2kw/grade4

- The number of roller wheels: 4 pcs

- The number of bottle worm shaft: 1pc

- dimension: 6m(L)*1.4m(W)*2m(H)

- The thickness of steel plate: 4mm

- The Dia. of bottom worm shaft:400mm

- Bottom thickness helical blades:5mmWith working platform,and bottle cap collecting machine

All the production process is completed independently by our factory

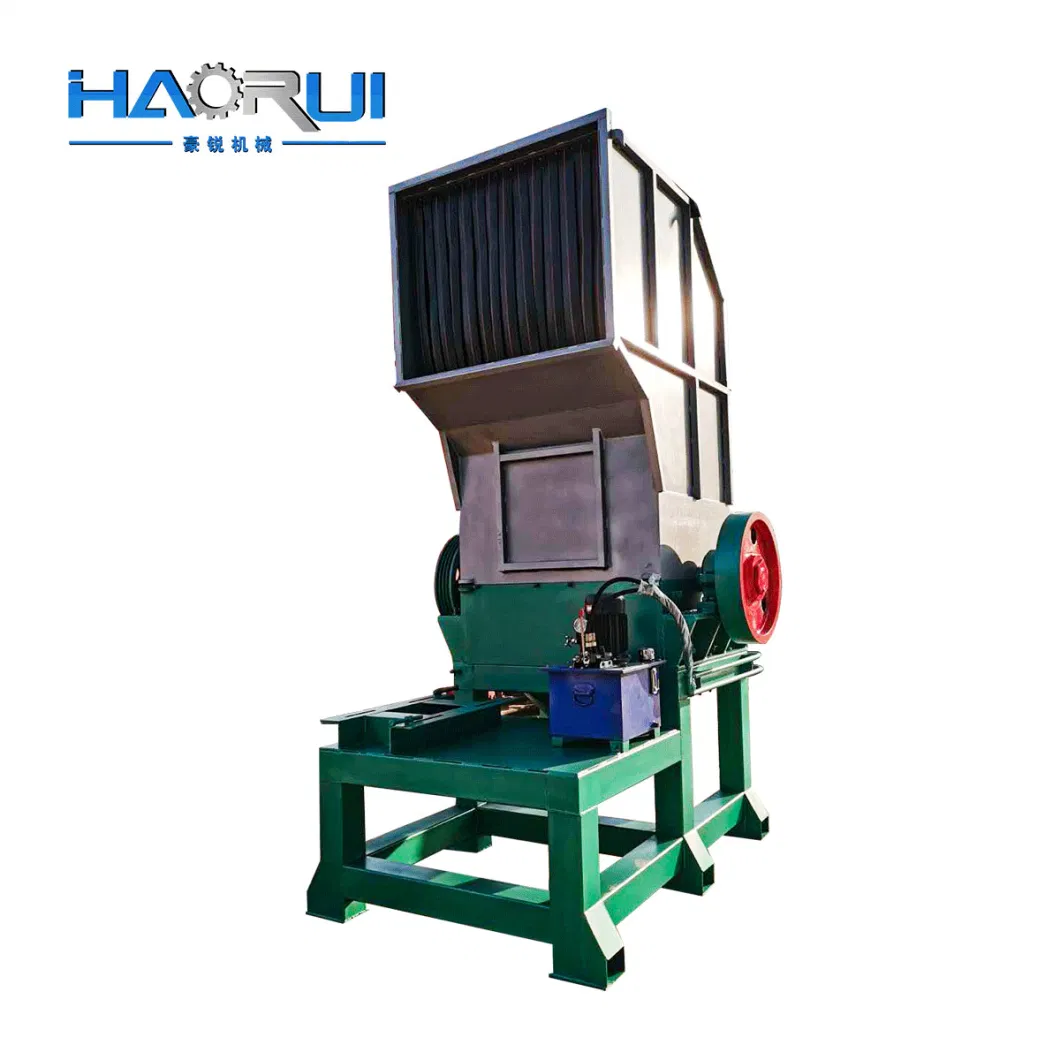

Usage:crusher the plastic into flakes

- 22kw to 110kw different models,capacity update to 3000kg/h

- PP PE bottle ,PP PE film/bag , PET bottle, different blade design according to customer material

- Heavy duty model, high speed crushing

- Film crusher, V type blade, special angle,increase the capacity ,Prevents material from snagging the blade.

Advantage:

- Capacity up to 3500kgs/h

- Unique design blade quantity and shape,with patent certification.

- Most hot-selling item, 98% customers gave good feedback.

- High label remove rate(round bottle> 99% , bale bottle> 96% )

- Don't damage bottles, reduce neck broken, reduce material loss.

- Good design label separation chamber, can used for wet bottle, label come out well, not block.

Packaging&Shipping

Company Profile

Baoding Haorui Machinery Manufacturing Co.,ltd was established in 1992,is a professional manufacturer and exporter that is concerned with the design,development and production of PET bottle crushing and washing machine, PP PE HDPE LDPE plastic crushing and washing machine, pelletizing machine .

There are over 100 technicians in our workshops which covers 20000 square meters. Over 28 years of plastic recycling machines production experience ,enable us to be TOP3 plastic recycling machine factory in China. Our own R&D team make our machine design unique, OEM and ODM service are also welcome. Our main products include bale opener, label remover, plastic crusher, floating tank, screw feeder, high-speed friction washer , hot / cold washer, dewatering machine, pipe dryer and so on.

We insist on the principle of "quality is first" and inspect the machine after producing " which make our market more popular in Domestic and over 40 sets of PET bottle washing line(four 6000kg/h capacity in Nigeria ,Ghana etc), PP PE HDPE LDPE washing line ,pelletizing machine were installed in Middle East,Africa,South America,South East, South Asia and so on

Factory

successful case

our advantage

our advantage

FAQ

Q: How often are the Crusher blades sharpened?

A: After continuous working at 30-40hours, the blades have to be sharpened

Q: How long does it take for changing blades-Remove and install blades?

A: Depending on the worker skilled or not. Normally 2-3hours

Q: How about the rate for removing the labels by Label remover?

A: Compressed bottle: more than 96%

Un-compressed bottle: more than 98%

Q:What's the temperature of steam washer ?

A: Usually 80-90ºC ( If the temperature is over 100ºC, the Flake will be roll.so the best temperature

is 80-90ºC)

Q: What's the moisture after Horizontal dewatering machine?

A: About 1.8%. Adopt Swedeen SKF bearing, with bearing layer on the surface of screw blades

for longer working life.

Q: How often are the Crusher blades sharpened?

A: After continuous working at 30-40hours, the blades have to be sharpened

Q: How long does it take for changing blades-Remove and install blades?

A: Depending on the worker skilled or not. Normally 2-3hours