Basic Info.

Model NO.

MT-12

Working

High Speed Mixer

Stirring Type

Spiral

Application

Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid, Granules

Certification

CE

Application Area

Pharmaceutical

Layout Type

Horizontal

Mixing Drum Shape

Drum

Additional Capabilities

Drying

Operating type

Continuous Operating

Condition

New

Usage

Oil, Liquid, Milk, etc

Heating Method

Electric or Steam Heating Method

Core Components

Motor, Pressure Vessel, Gearbox, Pump, PLC

Capacity

100L -100000L, Can Be Customized

Function

Heating/ Cooling, Blending, Emulsifying, Mixing

Transport Package

Wooden Case with Steel Frame

Specification

stainless steel

Trademark

JNBAN

Origin

Wenzhou, China

Production Capacity

5000pieces/Year

Packaging & Delivery

Package Size

180.00cm * 300.00cm * 480.00cm

Package Gross Weight

400.000kg

Product Description

The Marked Prices Of Our Products Are All Range Prices Of The Entire Product Series.

If You Need a Detailed Quotation, Please Send An Inquiry At The Bottom Of The Page.

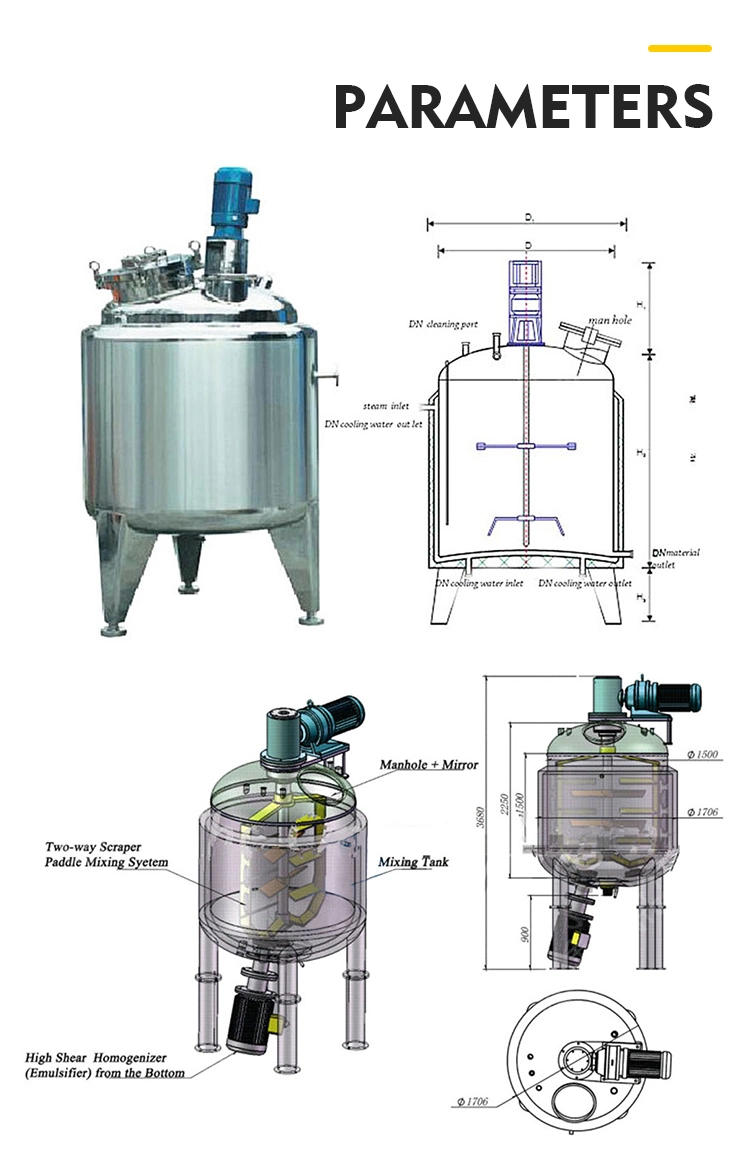

stainless steel mixing tank

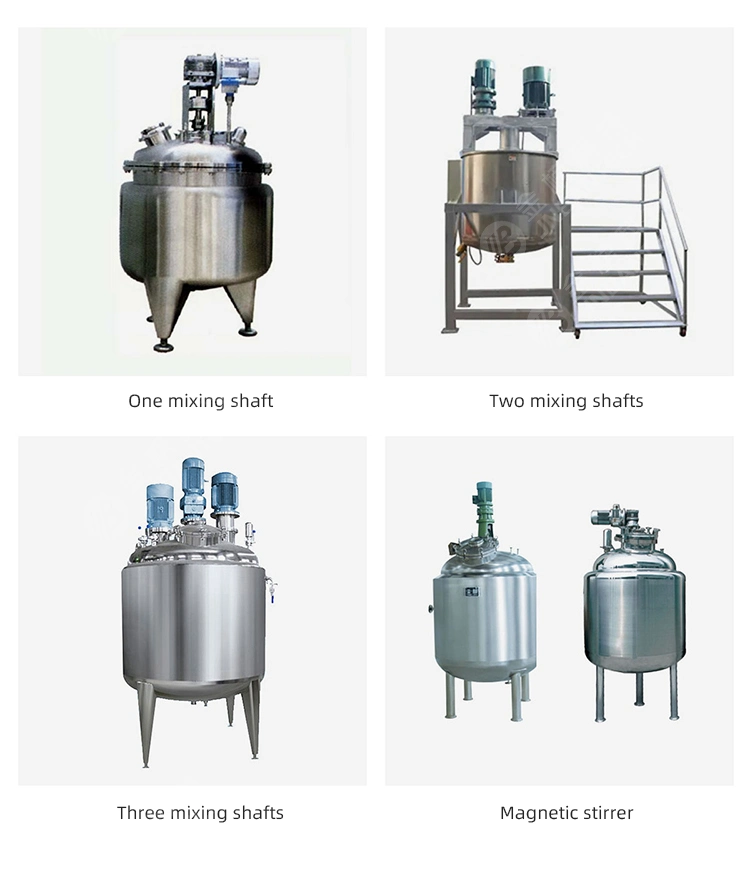

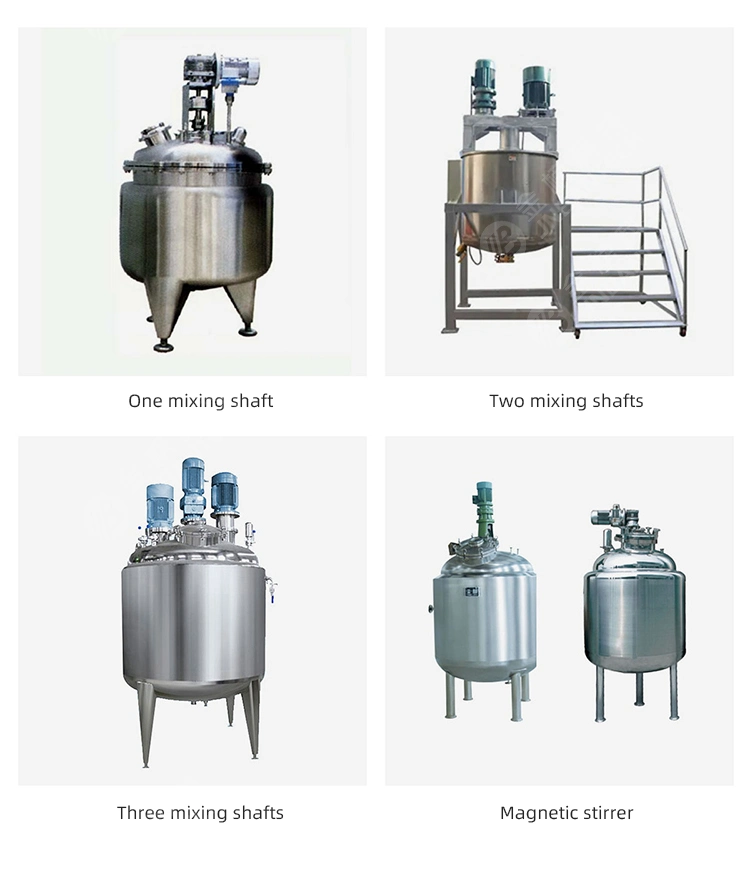

Mixing tanks come in various sizes and can be used in a wide range of industries.Our mixing tanks start as small as 50 liter but can go up to 10000 liter or even bigger. For processes such as mixing, blending, keeping it homogenious, an efficient agitator or a combination of agitators is necessary. Let us know what you would like to achieve, and we will collaborate with you in order to arrive at the most efficient solution.

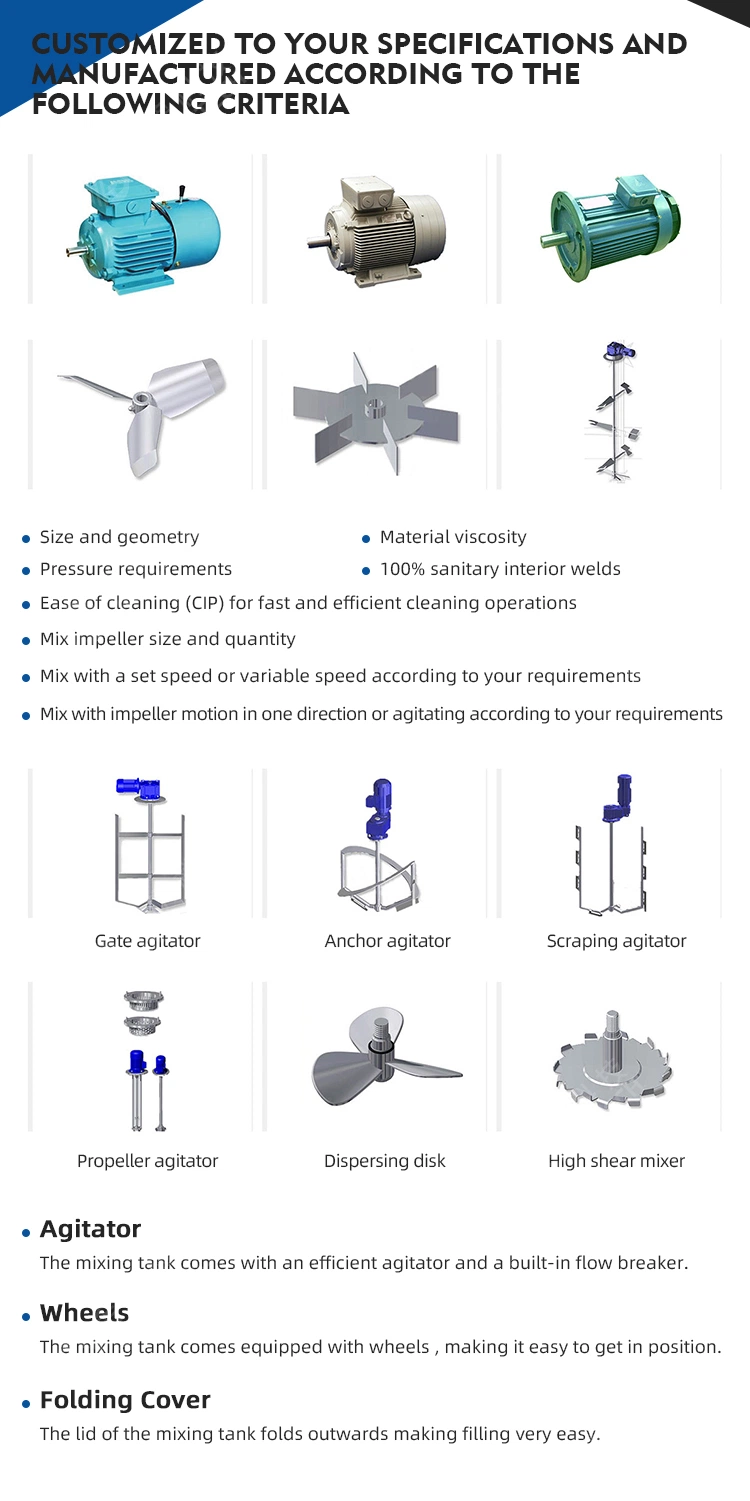

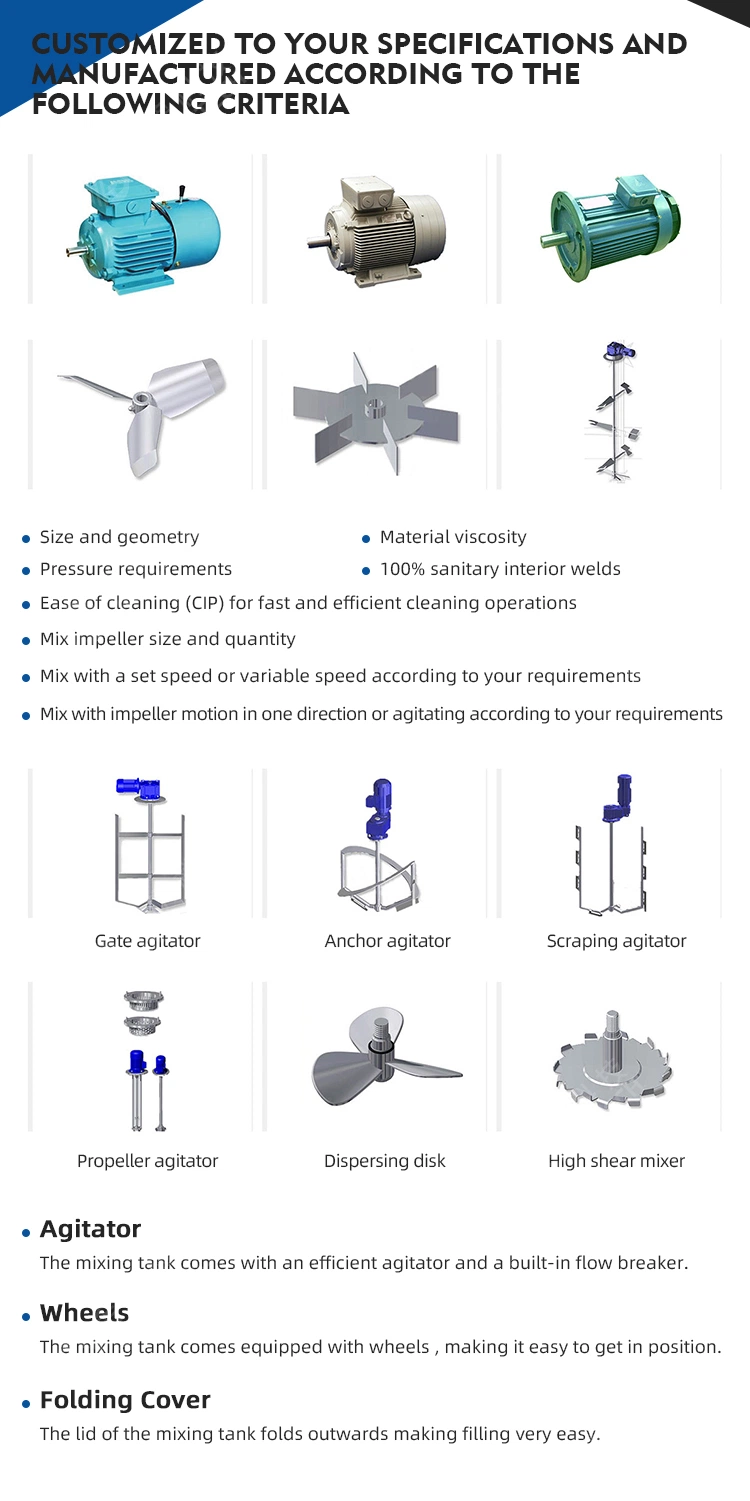

customized to your specifications and manufactured according to the following criteria:

1 Size and geometry

2 Material viscosity

3 Pressure requirements

4 100% sanitary interior welds.

5 Ease of cleaning (CIP) for fast and efficient cleaning operations

6 Mix impeller size and quantity

7 Mix with a set speed or variable speed according to your requirements

8 Mix with impeller motion in one direction or agitating according to your requirements

2 Material viscosity

3 Pressure requirements

4 100% sanitary interior welds.

5 Ease of cleaning (CIP) for fast and efficient cleaning operations

6 Mix impeller size and quantity

7 Mix with a set speed or variable speed according to your requirements

8 Mix with impeller motion in one direction or agitating according to your requirements

Manufacturing liquid products often requires mixing ingredients and then storing them. Whether your company is in the cosmetic, pharmaceutical, chemical, or food and beverage industry, there are various regulations you must meet. Our mixing and storage vessels are designed with your industry in mind. To best serve our customers, we've designed top-notch mixing tanks, storage tanks, flange-top mixing tanks, and cosmetic mixing tanks. Each of these tanks feature high-quality materials for optimal durability, reliability, and safety.

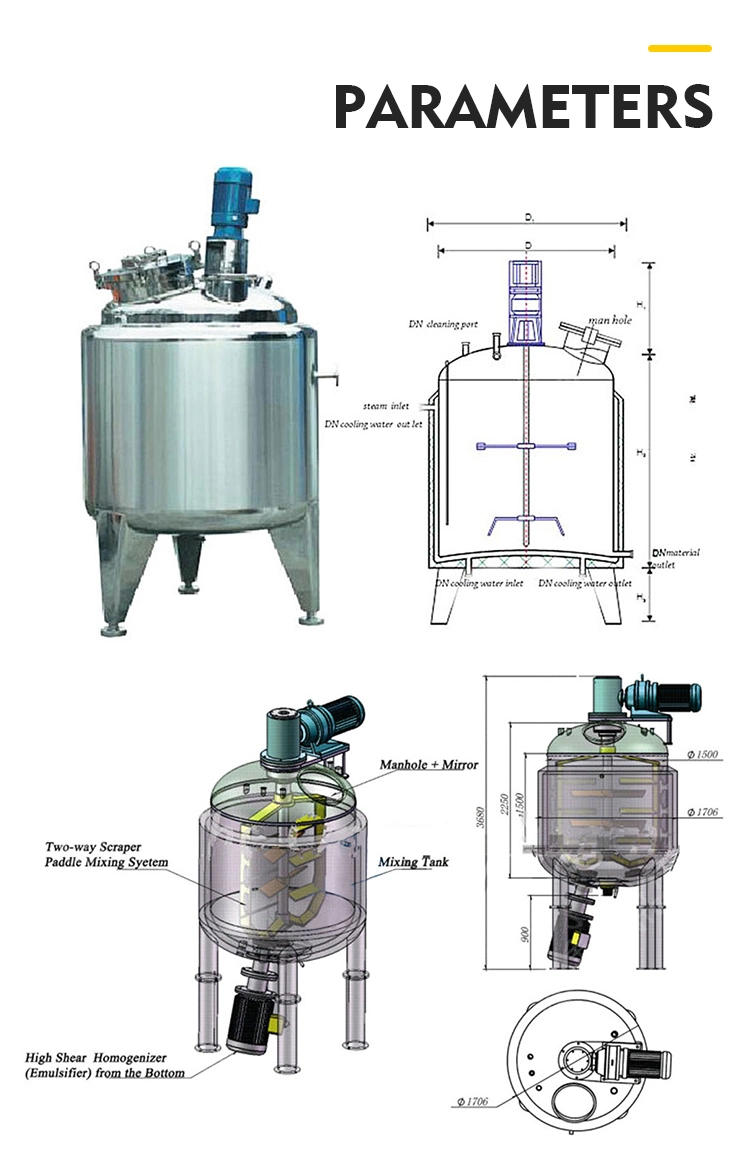

| Tank size (mm) | Frame power (kw) | Frame speed(rpm) | Disperserpower (kw) | Disperser Speed (rpm) | Screw power (kw) | Screw speed (rpm) | Emulsifier power (kw) | Emulsfiier speed (rpm) |

| φ950*800 | 3-5.5 | 0-75 | 11-18.5 | 0-1450 | 4-7.5 | 0-200 | 7.5-11 | 0-1500 |

| φ1200*1000 | 5.5-11 | 0-58 | 18.5-30 | 0-1450 | 7.5-15 | 0-180 | 15-22 | 0-1500 |

| φ1350*1100 | 7.5-15 | 0-58 | 22-37 | 0-1450 | 7.5-15 | 0-180 | 22-30 | 0-1500 |

| φ1450*1300 | 15-18.5 | 0-45 | 30-45 | 0-1450 | 11-18.5 | 0-160 | 30-37 | 0-1500 |

| φ1600*1600 | 18.5-22 | 0-35 | 45-55 | 0-1450 | 15-22 | 0-140 | 37-45 | 0-1500 |

| φ1900*1900 | 18.5-22 | 0-25 | 55-90 | 0-950 | 22-30 | 0-120 | 37-45 | 0-1500 |

| φ1900*1900 | 22-30 | 0-24 | 75-110 | 0-950 | 30-37 | 0-120 | ||

| φ1900*1900 | 22-30 | 0-22 | 90-132 | 0-950 | 37-45 | 0-100 | ||

| φ2400*2400 | 30-37 | 0-17 | 110-160 | 0-950 | 37-45 | 0-80 | ||