Basic Info.

Model NO.

Electronics contract manufacturer

Production Process

Subtractive Process

Base Material

Copper

Insulation Materials

Organic Resin

Brand

Zinpon Electronics

Surface Treatment

Enig2u′

Soldermask

Customized

Customization

Available

Certificate

UL#ISO9001#ISO45001#IATF16949

Transport Package

Vacuum Package with Desiccant and Humidity Cards

Specification

650mm*1200mm

Trademark

Customized

Origin

China

HS Code

8534009000

Production Capacity

50000square Meters Per Month

Product Description

1.Company Profile

ZINPON PCB is a leading manufacturer of high-density multi layer PCBs with more than ten years experience. 60% products are sold to Europe, America, Japan and other Asia-pacific countries. The high quality of our products and short lead time brought us reputation and recognition worldwide.We specialize in providing PCB prototype and mid-volume production with a diversified range of materials. Our capabilities allow us to provide you with printed circuit board solutions to all your leading-edge technology needs. Quality and service are the foundation to help us build long-term business partnerships with our customers.

Adhering the mission to "offer customer satisfy product, offer stuff satisfy work, offer socially satisfied enterprise ", and the core value to "Customer orientation is one of ZINPON's core values and we are committed to providing the customer with high quality and efficient service. ",ZINPON PCB will realize noble vision" to be an excellent PCB supplier of the global electronics industry".

2.FAQ

1.Can you offer PCB design services?

Yes,we have several PCB design team for your concept to manufacturing services.

2.How to guarantee the PCB and PCBA quality?

We do SPI, AOI,X-RAY, for PCBA ,AOI Scanning and flying probe test #fixture test for PCB BARE BOARDS.

3.What files formats do we need for PCB quotation.

we accept the Allegro#PADS#Altium#protel#Gerber#odb+ format etc

3.Technical Capability

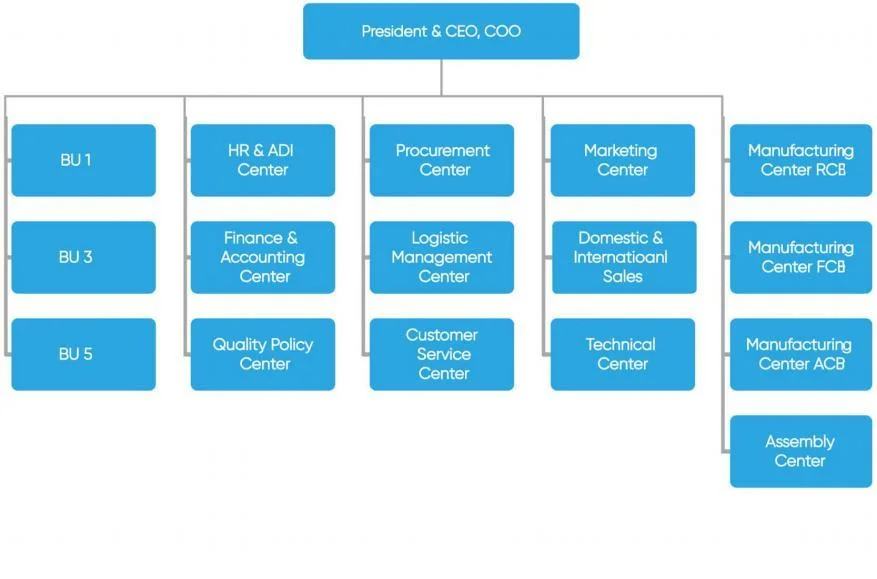

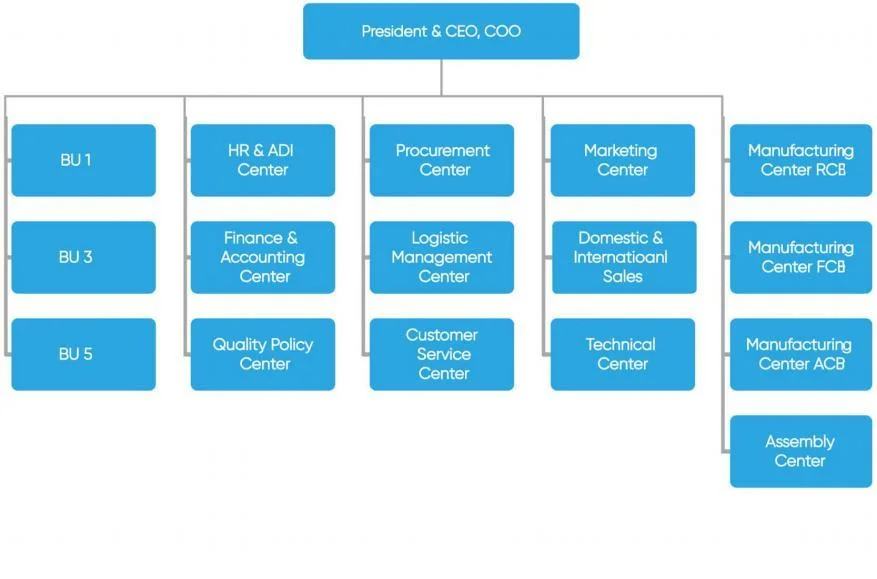

Company structure.

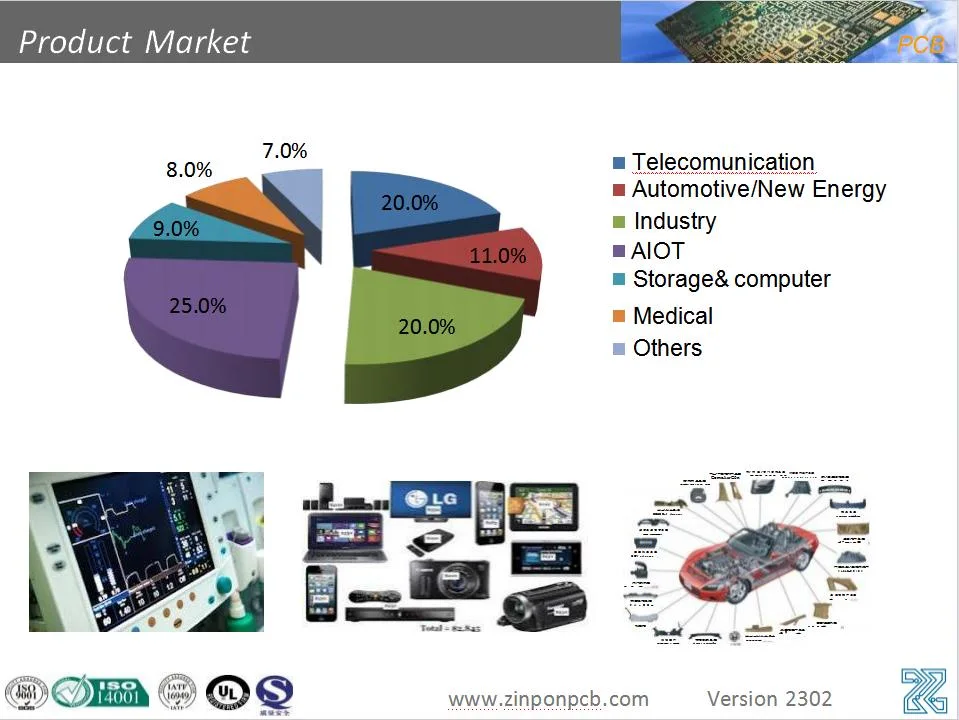

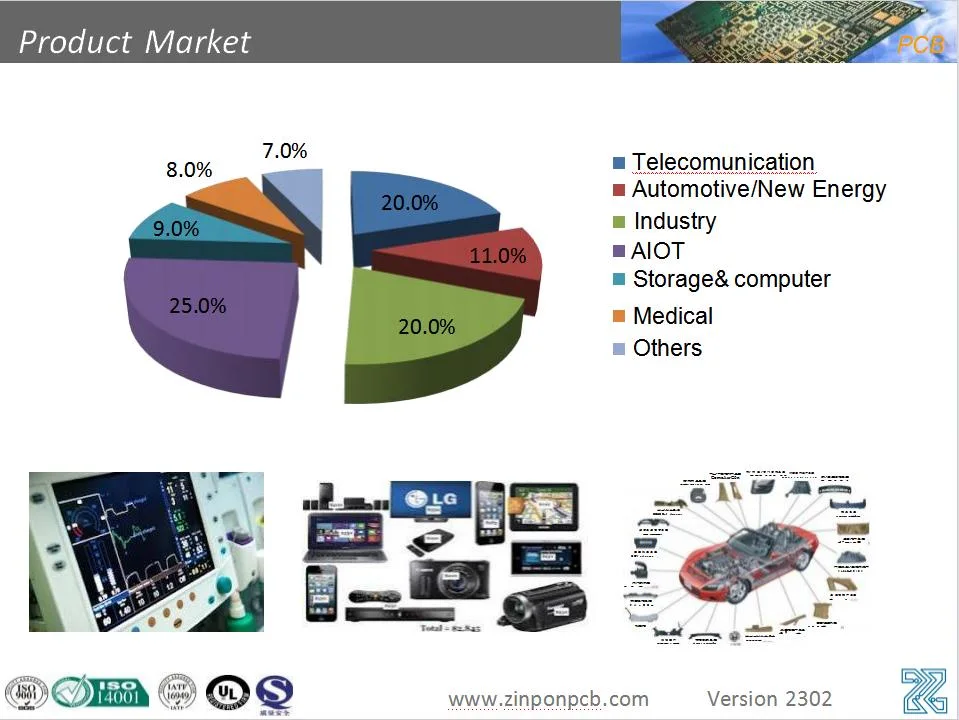

Product Market

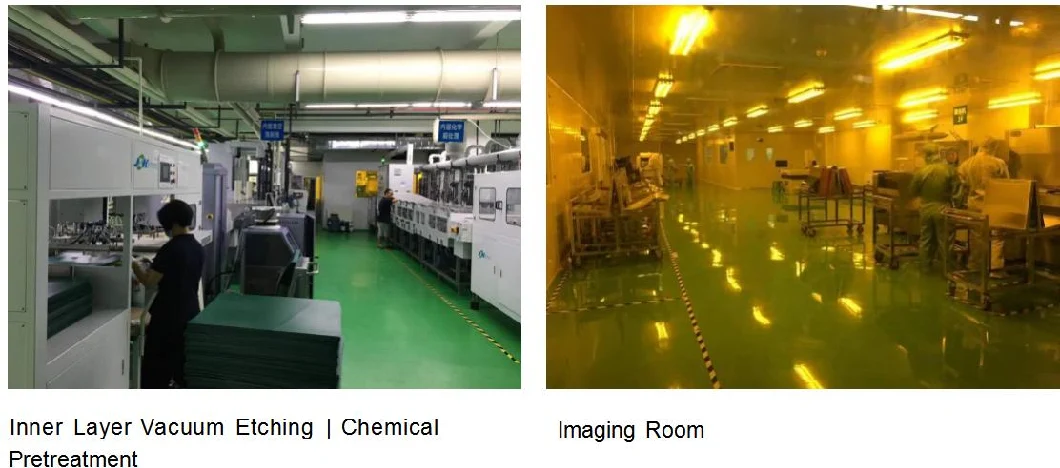

PCB Manufacturing facilities

PCB Assembly Facilities

PCBA Equipment List

PCBA Capability

1.7 Sony High-Speed SMT Lines

2.8Millions daily SMT Placements Capability

3.1Million daily DIP Placements Capability

4.680x500mm Maximum Board Size

5.0.25"x 0.25" Minimum Board Size

6.450mm Max.Width for Wave-Solder

7.Passives Components Down to 0201 Size BGA and VFBGA Lead less Chip Carrier/CSP Double- Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and

Replacement

SMT and Thru-hole

0-50KN Press Range

Top120mm/Bot15mm component height

High speed:0.15sec/chip 0.7sec/QFP

X-RAY Inspection

AOI Testing

in-circuit-test

Flying Probe

Burn-in

Function Test

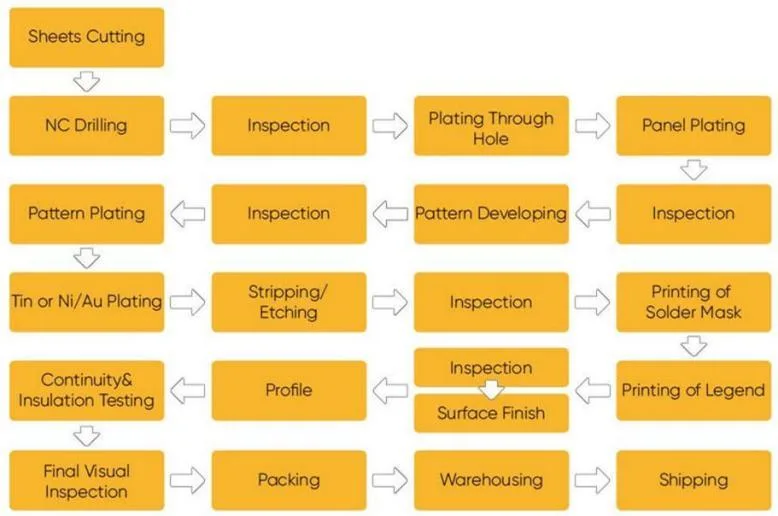

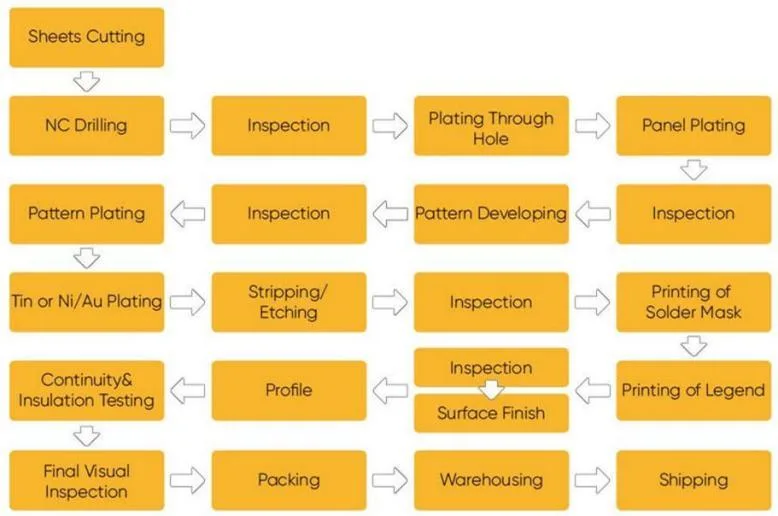

Rigid PCB Process flow

Aluminum PCB Process flow

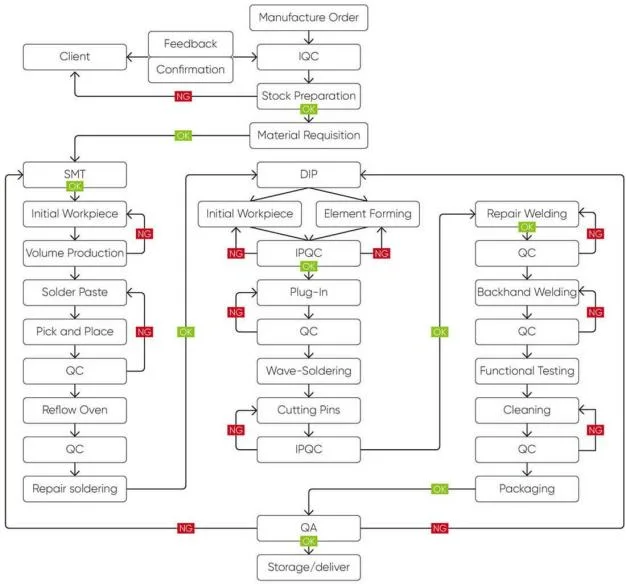

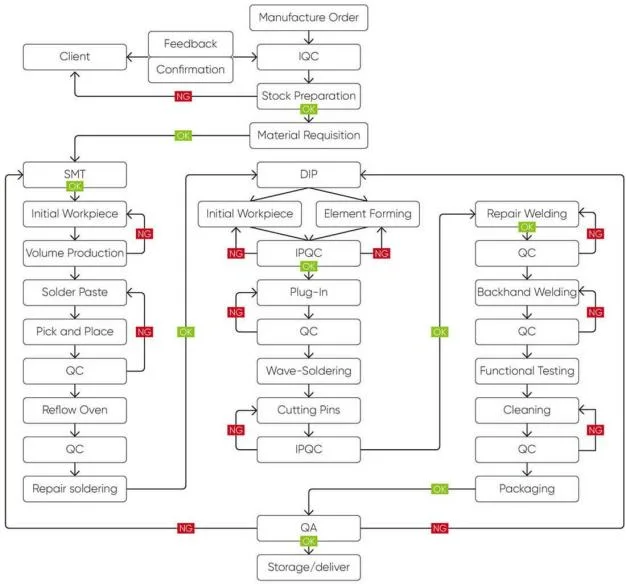

PCBA Process flow

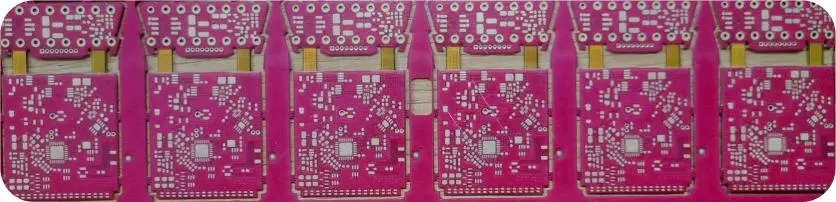

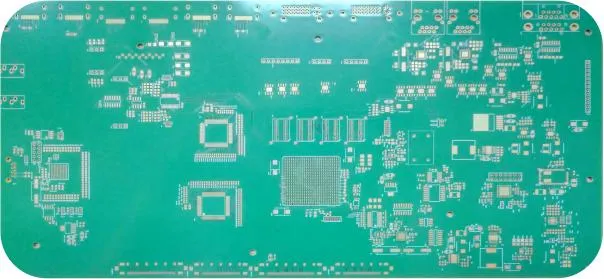

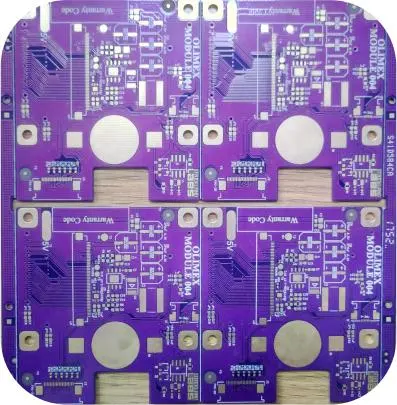

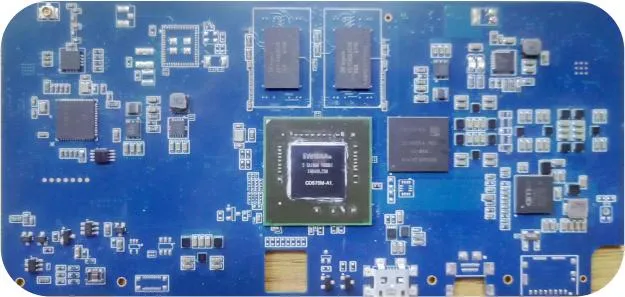

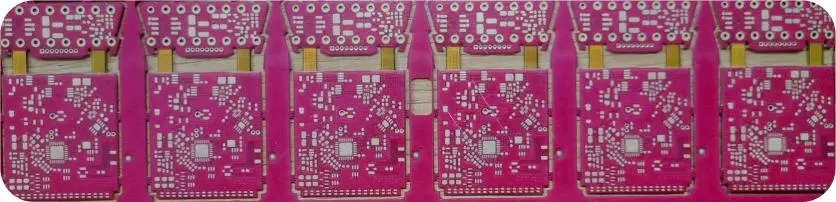

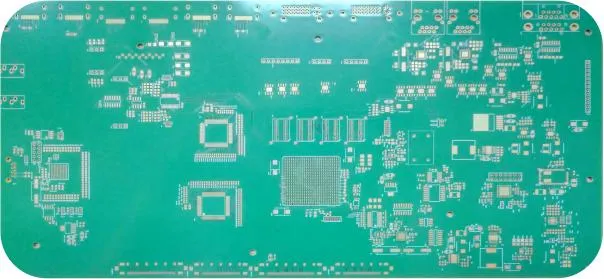

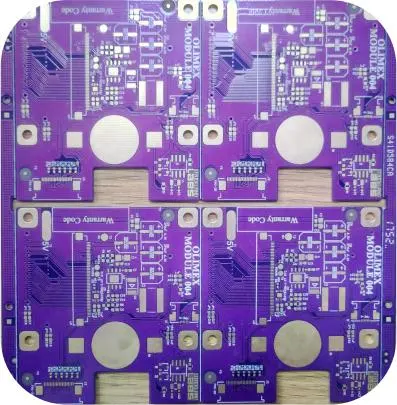

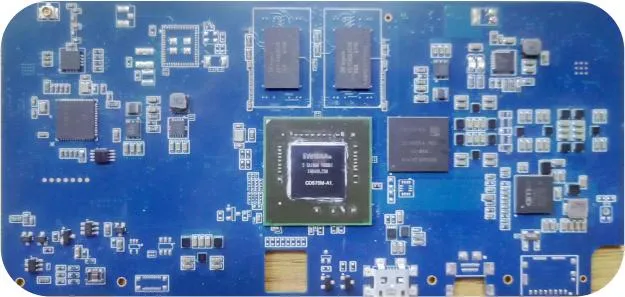

Some Products

Some Products

6 layer rigid-flex pcb, Car OBD Project

6 layer rigid-flex pcb, Car OBD Project

4 layer pcb, consumer electronics

4 layer pcb, consumer electronics

12 layer pcb, smart home project

12 layer pcb, smart home project

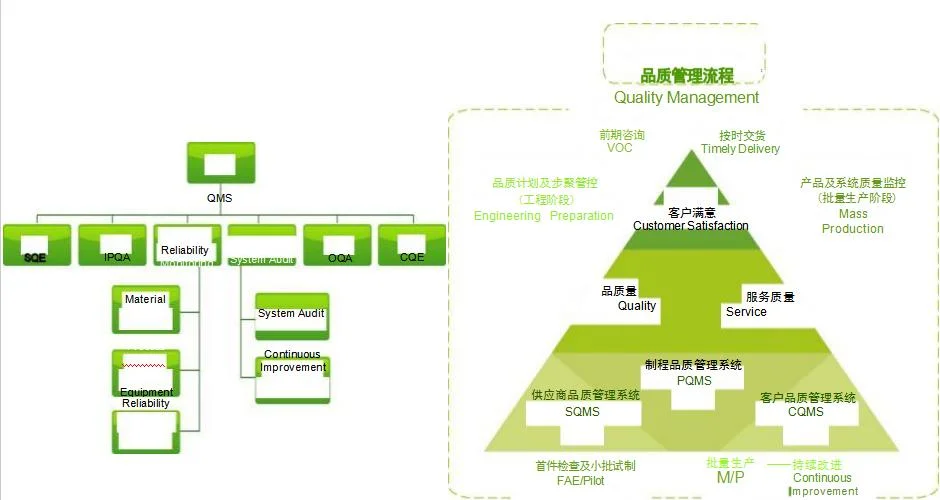

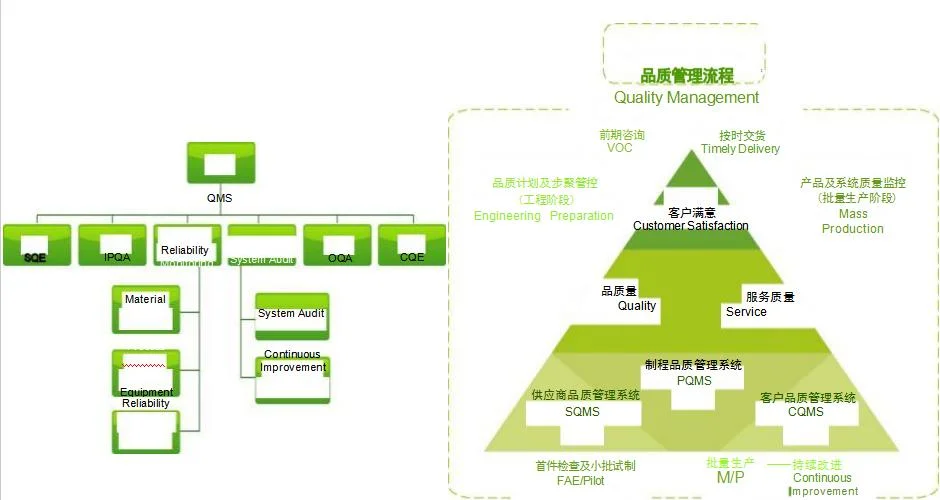

Quality Management

Quality Management

Fast Response services

Door to door Services

ZINPON PCB is a leading manufacturer of high-density multi layer PCBs with more than ten years experience. 60% products are sold to Europe, America, Japan and other Asia-pacific countries. The high quality of our products and short lead time brought us reputation and recognition worldwide.We specialize in providing PCB prototype and mid-volume production with a diversified range of materials. Our capabilities allow us to provide you with printed circuit board solutions to all your leading-edge technology needs. Quality and service are the foundation to help us build long-term business partnerships with our customers.

Adhering the mission to "offer customer satisfy product, offer stuff satisfy work, offer socially satisfied enterprise ", and the core value to "Customer orientation is one of ZINPON's core values and we are committed to providing the customer with high quality and efficient service. ",ZINPON PCB will realize noble vision" to be an excellent PCB supplier of the global electronics industry".

2.FAQ

1.Can you offer PCB design services?

Yes,we have several PCB design team for your concept to manufacturing services.

2.How to guarantee the PCB and PCBA quality?

We do SPI, AOI,X-RAY, for PCBA ,AOI Scanning and flying probe test #fixture test for PCB BARE BOARDS.

3.What files formats do we need for PCB quotation.

we accept the Allegro#PADS#Altium#protel#Gerber#odb+ format etc

3.Technical Capability

Company structure.

Product Market

PCB Manufacturing facilities

PCB Assembly Facilities

PCBA Equipment List

| Main Equipment Item | Qty | Main Equipment Item | QTY |

| SONY High-speed SMT SI-F130WR | 16 | ChaojinDa Full-automatic Ultrasonic Cleaning Machine | 3 |

| DESEN Automatic silk-screen Machine DSP-1008 | 8 | Yongxing Industrial Oven | 3 |

| Youngxin lift Slab Machines BL-250W-ST | 8 | Automatic Belt-type Cleaning Packagine Production Line | 2 |

| Automatic Belt-type Post-welding production Line | 5 | Automatic Double-Wave-peak welding Line | 2 |

| YAMAHA Multi-functional SMT YV100XGP | 4 | 3D-SPI inspection Equipment | 2 |

| SONY Multi-functional SMT SI-F209 | 4 | Computer Test Maintenance Equipment | 1 |

| Online AOI Inspection Equipment | 4 | Automatic Belt-type Assembly Line | 1 |

| US Heller18 Zones Reflow Oven | 4 | US PACEB BGA Repair Station | 1 |

| SONY High-speed SMT SI-F130WR | 4 | Japanese X-RAY Detector | 1 |

PCBA Capability

1.7 Sony High-Speed SMT Lines

2.8Millions daily SMT Placements Capability

3.1Million daily DIP Placements Capability

4.680x500mm Maximum Board Size

5.0.25"x 0.25" Minimum Board Size

6.450mm Max.Width for Wave-Solder

7.Passives Components Down to 0201 Size BGA and VFBGA Lead less Chip Carrier/CSP Double- Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and

Replacement

SMT and Thru-hole

0-50KN Press Range

Top120mm/Bot15mm component height

High speed:0.15sec/chip 0.7sec/QFP

X-RAY Inspection

AOI Testing

in-circuit-test

Flying Probe

Burn-in

Function Test

Rigid PCB Process flow

Aluminum PCB Process flow

PCBA Process flow

Some Products

Some Products 6 layer rigid-flex pcb, Car OBD Project

6 layer rigid-flex pcb, Car OBD Project  4 layer pcb, consumer electronics

4 layer pcb, consumer electronics  12 layer pcb, smart home project

12 layer pcb, smart home project  Quality Management

Quality Management

Fast Response services

| Layers | QTA | Mass production |

| 2 Layers | 24 Hours | 10 days |

| 4 Layers | 48 Hours | 12 days |

| 6 Layers | 48 Hours | 14 days |

| 8 Layers | 72 Hours | 15 days |

| 10 Layers | 96 Hours | 18 days |

| 12 Layers | 120 Hours | 18 days |

| 14 Layers | 120 Hours | 20 days |

| Above 16 Layers | Depends on the specific requirments | |

| Note: -Above lead time base on EQ clearly and materail available. -Above lead time base on general techologies.Specail requirments will need extended days. | ||