Basic Info.

Model NO.

ccl001

Annual Design Production Capacity

320 Thousand Tons

Thickness

0.18-1.2mm

Width

800-1250mm

Product Weight

<10tons

Spangle

Zera/Nomal/Big/Small

Medium and Small Zinc Flower

Non-Chromated, Chromated

Technology

Reduction Method Hot DIP Galvanizing

Transport Package

Standard Seaworthy Package

Specification

steel

Origin

China

Production Capacity

2400000

Product Description

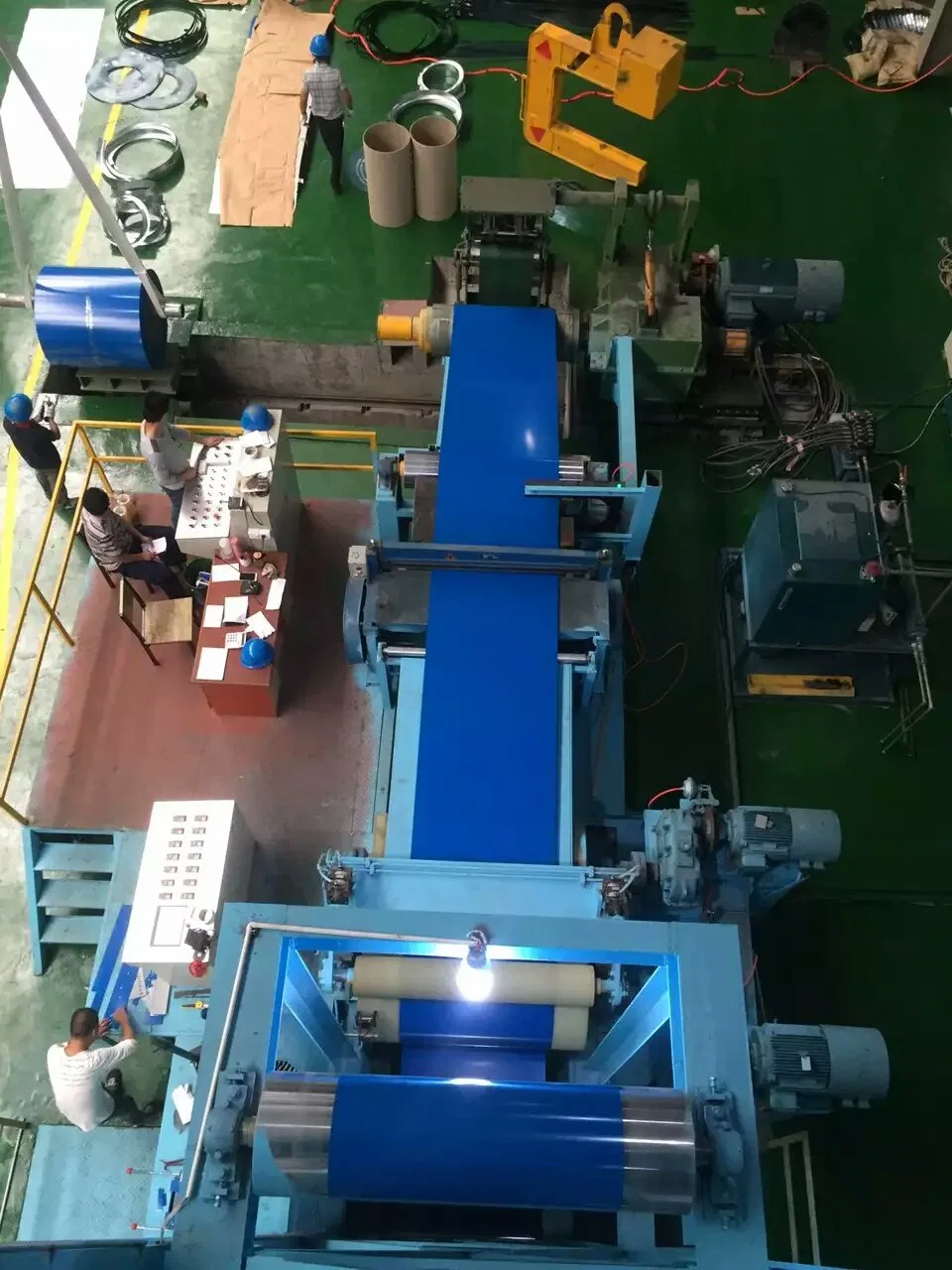

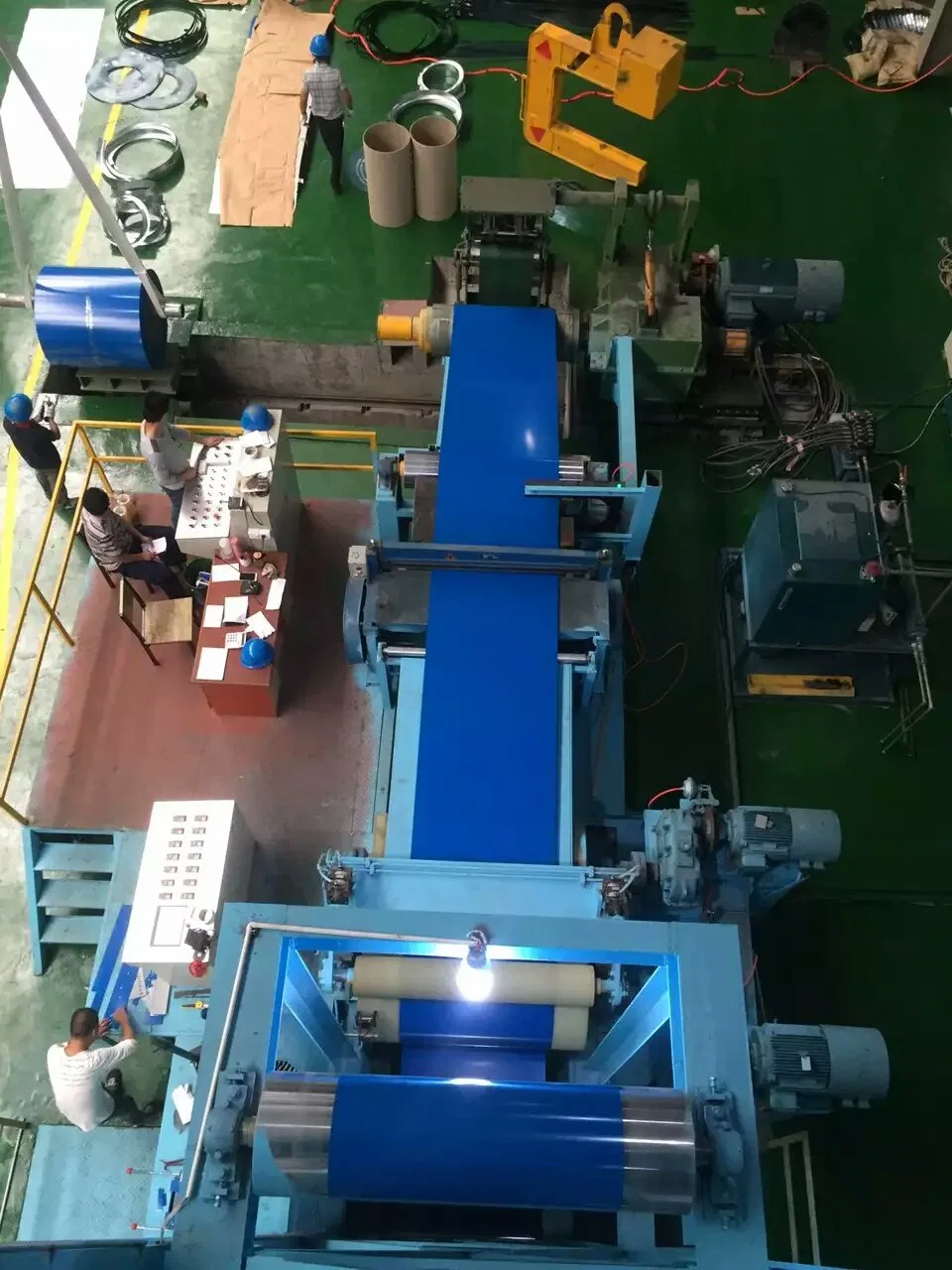

Color coating production line is one or several kinds of organic coating coated on the surface of steel (aluminum), it has a beautiful appearance, colorful, high strength, good corrosion resistance, processing and forming convenient advantages, but also allows users to reduce costs, reduce pollution.

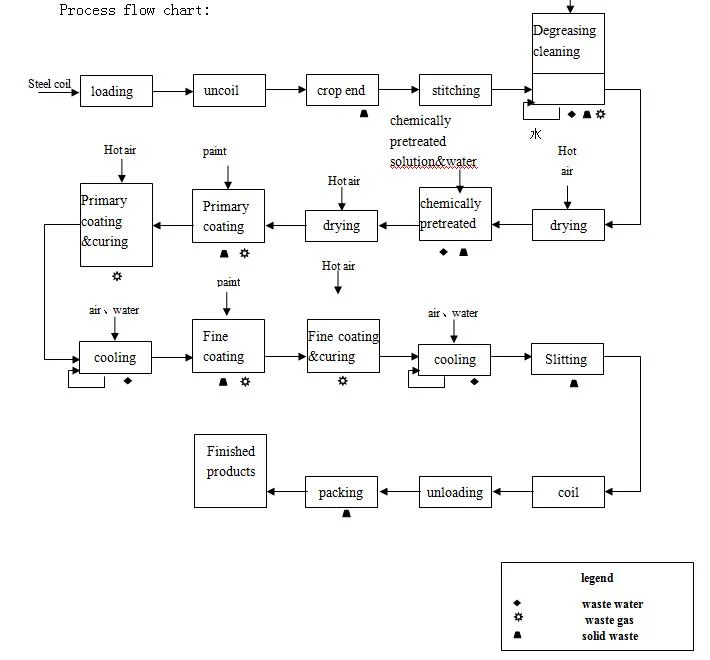

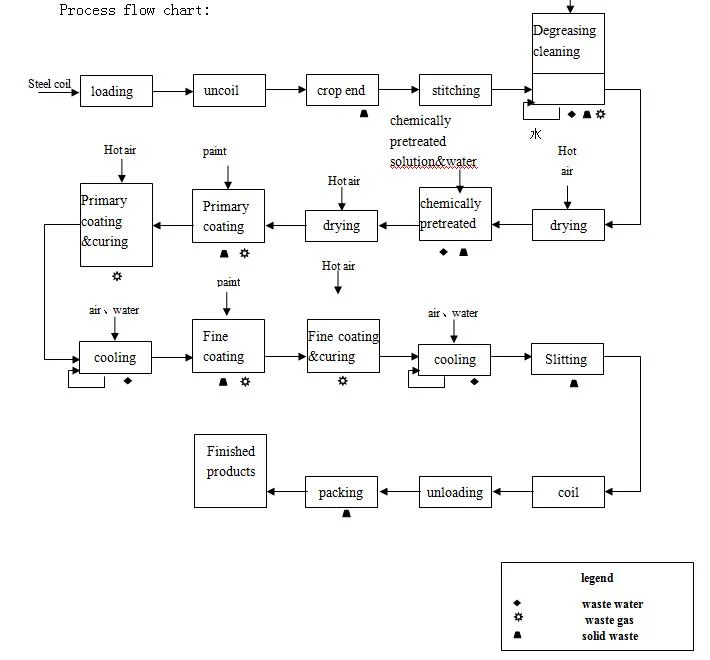

This color coating line is used for aluminium foil, steel coil color coating, decorative pattern printing and surface embossing etc. Its process flow mainly includes surface chemical treatment, powder coating, heating and solidification. These aluminum coil coating line can be differently combined according to customers' requirement.

Brief Introdution of Color Coating Line

The color coating plate is mainly based on cold rolled plate, galvanized steel plate and aluminium alloy plate. This kind of plate has advantages of corrosion resistance and decoration, as well as directly providing raw material for construction industry, automobile manufacturing, electric and others.

Line Main Properties:

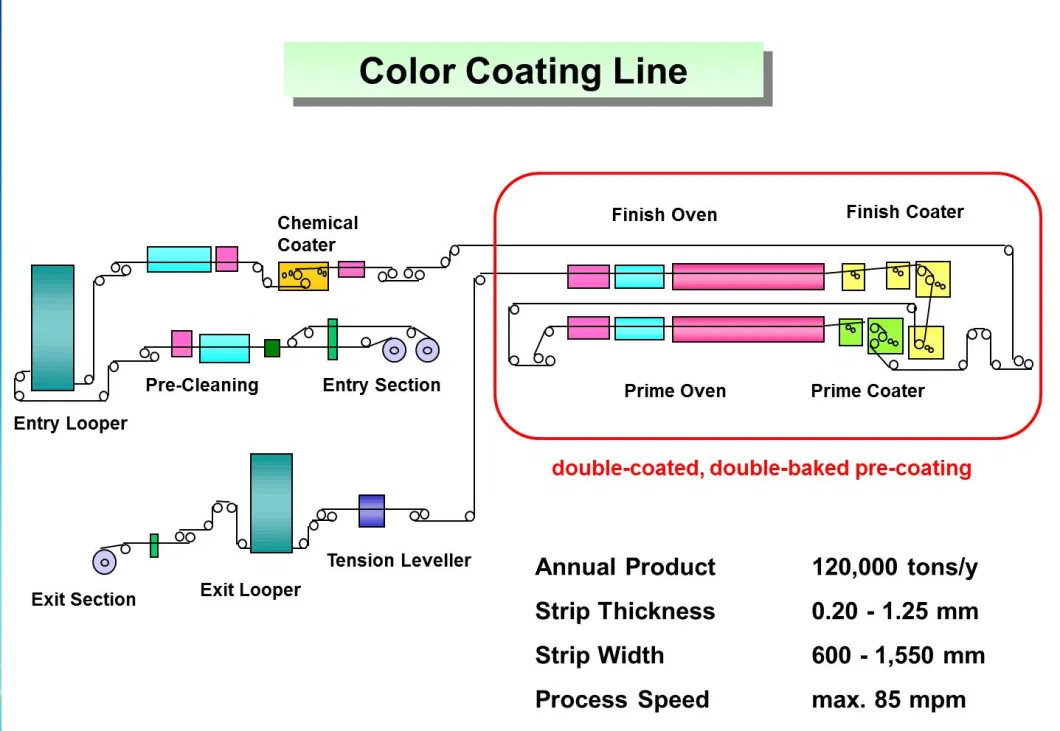

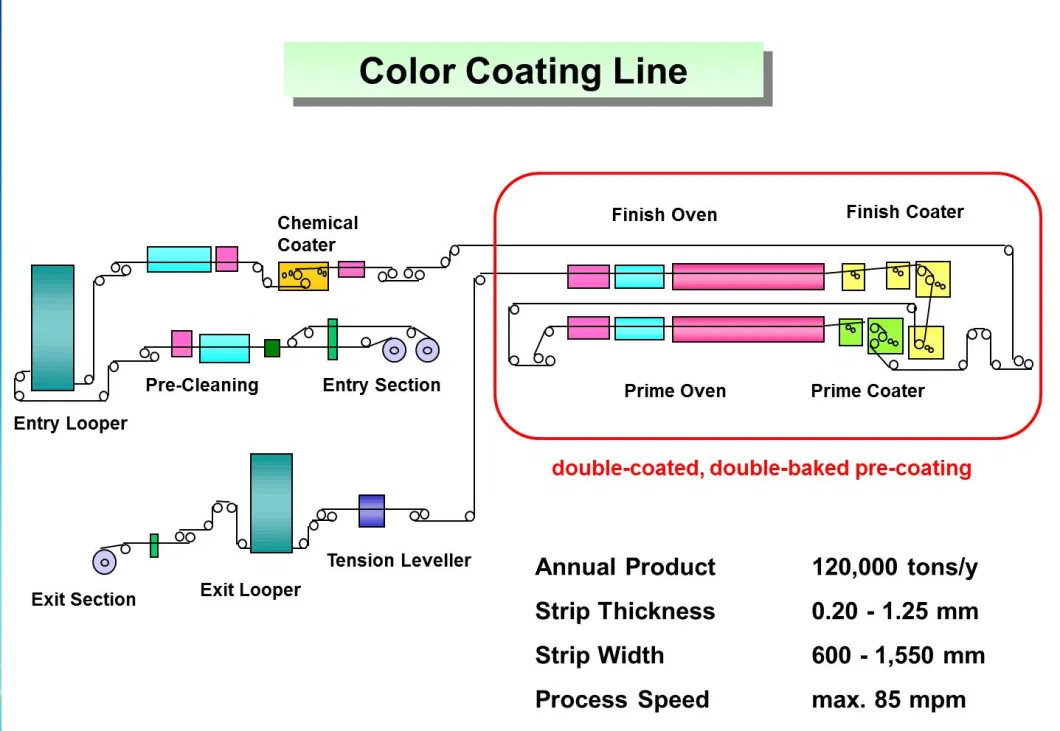

1. Line Type: two coating and two baking, three coating and three baking.

2. Product Grade: construction plate, decoration plate and household appliance plate.

3. Coating: Type: epoxy resin, polyurethane, polyester, polypropylene, polyvinyl fluoride, silicon modified polyester Dry film total thickness: min:23μm, max70μm.

4. Other treatment: printing, hot laminating, cold laminating.

5. Chemical Coater: dual-head two-roll type (used in prime coating), three-roll type (used in finish coating front side), two-roll type (used in finish coating back side).

6. Energy saving method: cyclic utilization of hot air; light fiber furnace lining; fume duct behind TIC is equipped with exhaust gas, air and water heat-exchanger, which is used for line baking, heat supply and cleaning solution heat supply, or directly use heat exhaust gas after incineration to supply heat for baking furnace; fume duct behind RTO and CIUdad is equipped with hot water heat-exchanger for cleaning solution heat supply.

Steel sheet coil coating & laminating machine is the completely production line to degreasing, phosphating and passivation first, second step is to continuous-rolling coating the gule or multilayer organic coating on the sheet surface, third step is to laminating the PVC, PET or other film by laminator after baking the sheetl to process temperature.

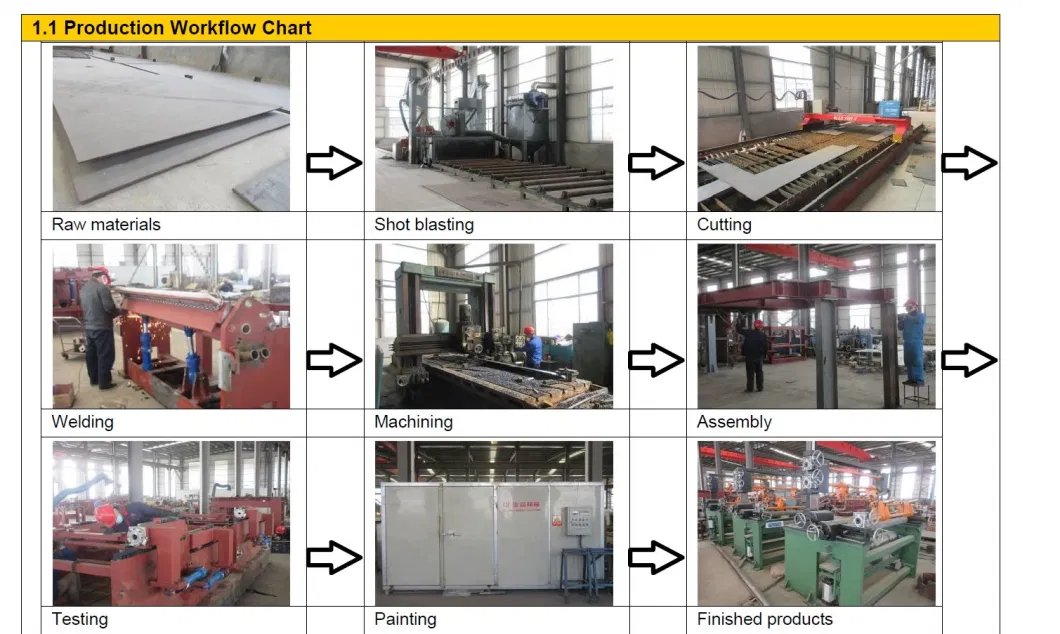

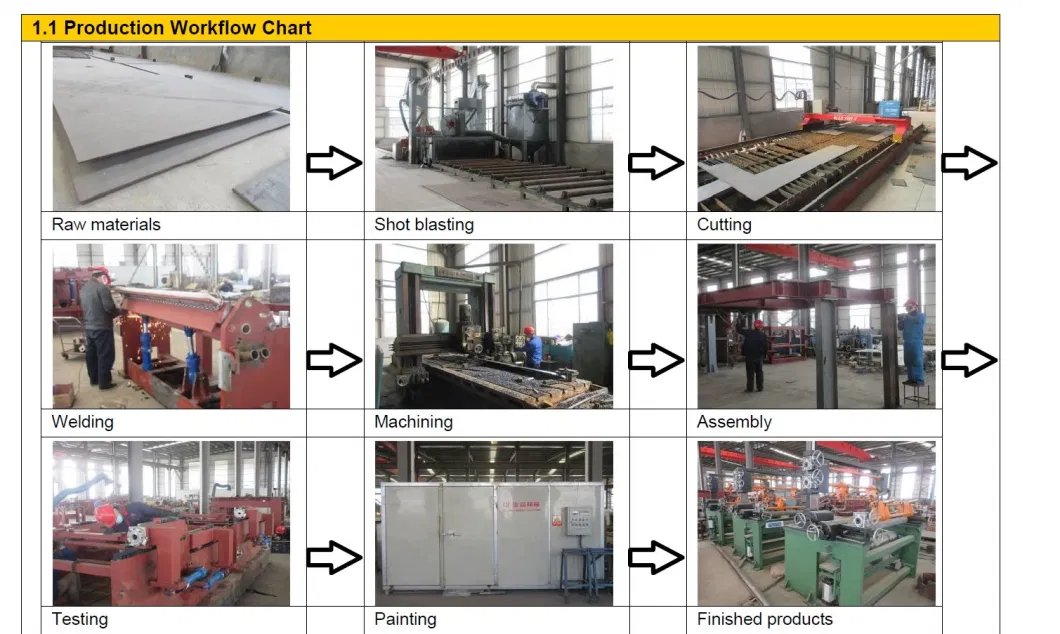

1. We are the leading manufacturer of metal coating machines in China, and we can give you the best price. We warmly welcome you to visit our factory at any time.

2. We have professional design engineers who can design and customize production lines according to your requirements.

3. Professional installation, good after-sales service and rich installation experience.

This color coating line is used for aluminium foil, steel coil color coating, decorative pattern printing and surface embossing etc. Its process flow mainly includes surface chemical treatment, powder coating, heating and solidification. These aluminum coil coating line can be differently combined according to customers' requirement.

Brief Introdution of Color Coating Line

The color coating plate is mainly based on cold rolled plate, galvanized steel plate and aluminium alloy plate. This kind of plate has advantages of corrosion resistance and decoration, as well as directly providing raw material for construction industry, automobile manufacturing, electric and others.

Line Main Properties:

1. Line Type: two coating and two baking, three coating and three baking.

2. Product Grade: construction plate, decoration plate and household appliance plate.

3. Coating: Type: epoxy resin, polyurethane, polyester, polypropylene, polyvinyl fluoride, silicon modified polyester Dry film total thickness: min:23μm, max70μm.

4. Other treatment: printing, hot laminating, cold laminating.

5. Chemical Coater: dual-head two-roll type (used in prime coating), three-roll type (used in finish coating front side), two-roll type (used in finish coating back side).

6. Energy saving method: cyclic utilization of hot air; light fiber furnace lining; fume duct behind TIC is equipped with exhaust gas, air and water heat-exchanger, which is used for line baking, heat supply and cleaning solution heat supply, or directly use heat exhaust gas after incineration to supply heat for baking furnace; fume duct behind RTO and CIUdad is equipped with hot water heat-exchanger for cleaning solution heat supply.

Steel sheet coil coating & laminating machine is the completely production line to degreasing, phosphating and passivation first, second step is to continuous-rolling coating the gule or multilayer organic coating on the sheet surface, third step is to laminating the PVC, PET or other film by laminator after baking the sheetl to process temperature.

| Product Name | Color coating line |

| Material | steel |

| Energy sources | water, electricity, Nature gas |

| Strip thickness | 0.2-2.5mm |

| Strip width | 1000-1500mm (max) |

| Weight | 300--400T |

| Size | 150m*18m*20m |

| Customized | Yes |

2. We have professional design engineers who can design and customize production lines according to your requirements.

3. Professional installation, good after-sales service and rich installation experience.