Basic Info.

Model NO.

YSST-270

Loading Method

Static Load

Display

Digital

Control

N/a

Weight

100-500Kg

Power Source

AC220V

Oil Cylinder Position

N/a

Inner Size

900*500*600mm

External Size

1380*800*1150mm

Volume

270L

Inside Chamber Temp. Range

Rt--50degrees, +/-0.5 Degree

Air Saturated Barrel Temp. Range

Rt--63degrees, +/-0.5 Degree

Salt Water Tank Temp. Range

Rt.-- 50degrees, +/-0.5degree

Exterial/Inner Material

Imported PVC & PP

Heating System

SUS#304 and SUS#316 S.S. Heater+Taflon

Salt Spray Veicle

Air+Acid Based Liquid

Power

AC 1 Phase 220V 50Hz

Transport Package

Strong Wooden Cases

Specification

CE, SGS, TUV certified.

Trademark

Yuanyao

Origin

Guangdong, China

HS Code

9031809090

Production Capacity

10 Sets/Month

Product Description

Introduction:

Compound salt spray test chamber can do the test of salt spraying, drying,wetting,soaking,constant temperature &humidity.It is widely applied to surface treatment of various materials, including, paint,electroplating,organic and inorganic coating, anodizing,corrosion rust oil products after testing its corrosion resistance.

Main features of the equipment:

1. Use imported PP & PVC for solid mechanical structure, good resistance to hydrochloric acid, heat resistance and never aging, suitable for salt fog copper acetate, etc.

2. Patent nozzle and conical diffusion device makes the fall fog rapidly and evenly. With manual level automatic control mode, the biggest setting time can reach 9990 hours.

3. Have automatic demist device, can clear observe tested products after the experience is finished.

4. Three complete temperature control systems(Saturated air temperature, the temperature in the cabinet, the test liquid temperature) ensure the consistency and standards of the test.

5. Meet international test standards.

6. Customization service is available & buyer's ideas are warmly welcomed.

For more technical details, please refer to the data sheet as attached.

Product detail:

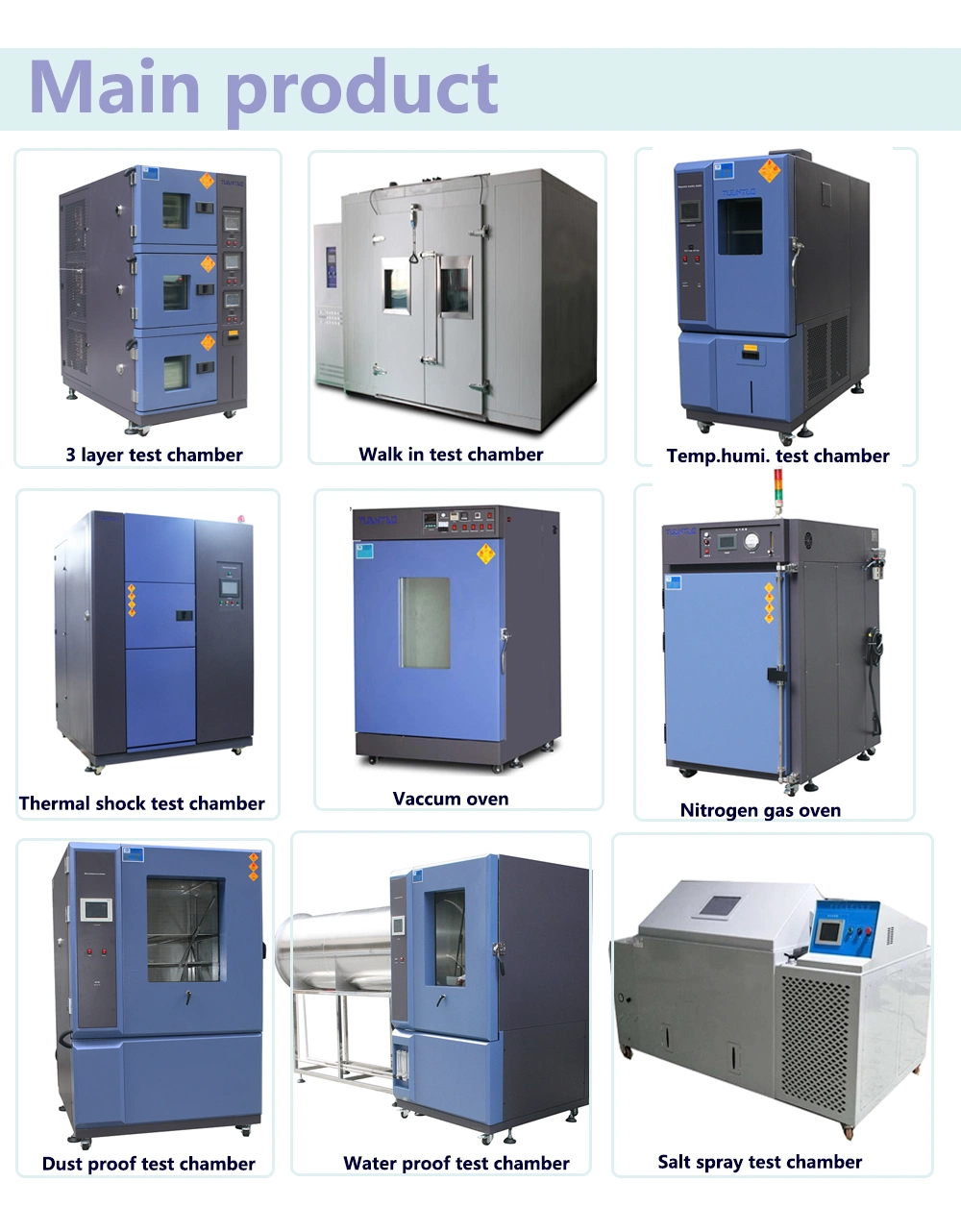

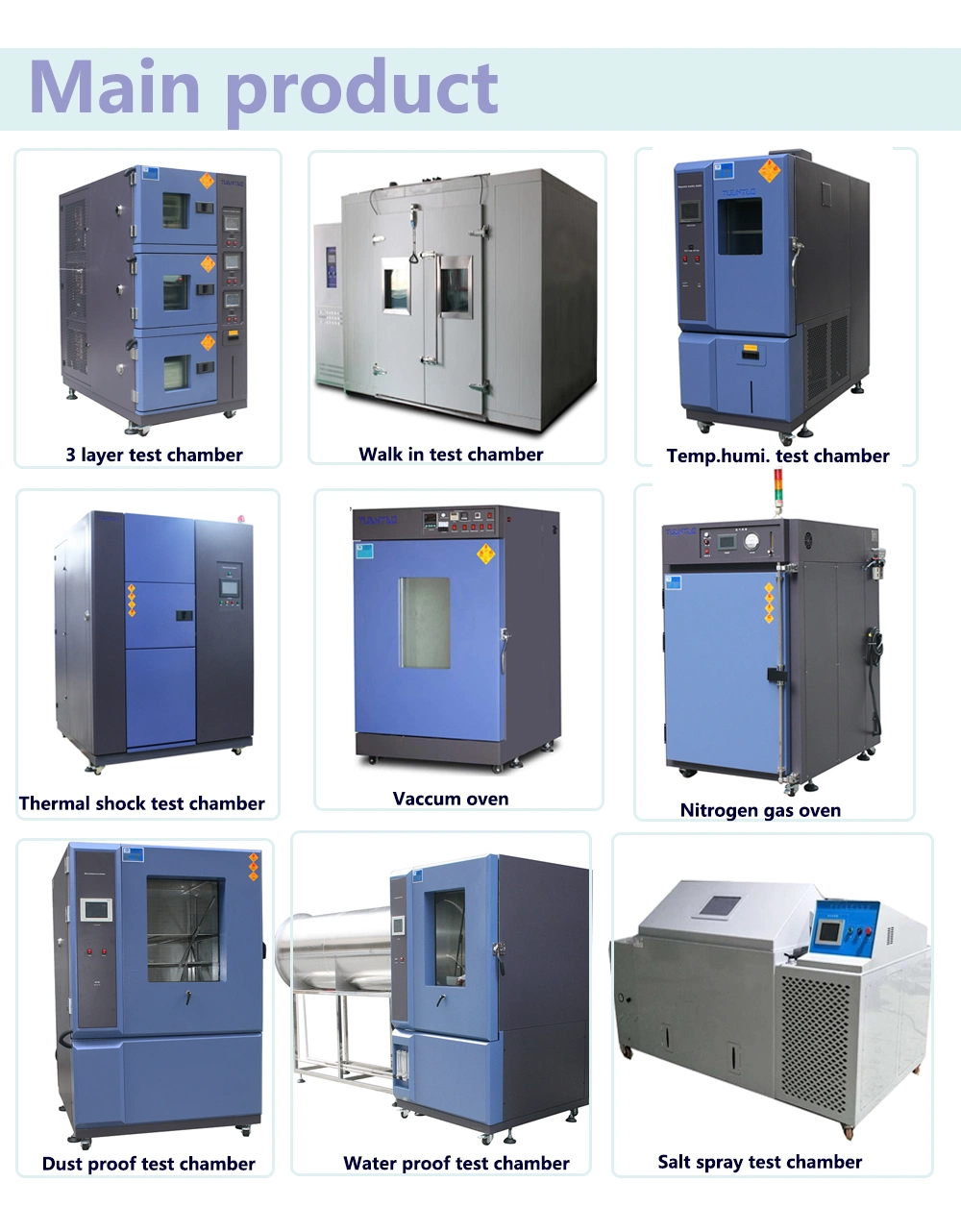

In addition to Compound salt mist corrosion test chamber, we are also manufacturing:

Precision Oven Tester, Triple Type Temp. & Humi. Chamber, Temp. & Humi. Control Host, Air Thermal Shock Tester, Liquid Thermal Shock Tester, Walk-in environmental Test Room, Temp. Humi. &Vibration Conbined Test Chamber, Aging Oven Tester, Rain/Spray Test Chamber, Burn-in test equipment, Dust Tester, Steam Aging Tester, Vibration Tester, Tensile Tester, Drop Tester and so on.

Company profile

Other styles / size with different configurations are available upon request, welcome to enquire and purchase!

Other styles / size with different configurations are available upon request, welcome to enquire and purchase!

Compound salt spray test chamber can do the test of salt spraying, drying,wetting,soaking,constant temperature &humidity.It is widely applied to surface treatment of various materials, including, paint,electroplating,organic and inorganic coating, anodizing,corrosion rust oil products after testing its corrosion resistance.

Main features of the equipment:

1. Use imported PP & PVC for solid mechanical structure, good resistance to hydrochloric acid, heat resistance and never aging, suitable for salt fog copper acetate, etc.

2. Patent nozzle and conical diffusion device makes the fall fog rapidly and evenly. With manual level automatic control mode, the biggest setting time can reach 9990 hours.

3. Have automatic demist device, can clear observe tested products after the experience is finished.

4. Three complete temperature control systems(Saturated air temperature, the temperature in the cabinet, the test liquid temperature) ensure the consistency and standards of the test.

5. Meet international test standards.

6. Customization service is available & buyer's ideas are warmly welcomed.

For more technical details, please refer to the data sheet as attached.

| Technical Specifications | |||||

| Model | YSST-108 | YSST-270 | YSST-600 | ||

| Internal Dim.WHD(mm) | 600*400*450 | 900*500*600 | 1200*500*1000 | ||

| External Dim.WHD(mm) | 1070*580*1030 | 1380*800*1150 | 1700*950*1150 | ||

| Temp. Range | Chamber | Room temp.-- 50ºC,±0.5ºC | |||

| Air | Room temp.--63ºC,±0.5ºC | ||||

| Salt | Room temp.--50ºC,±0.5ºC | ||||

| Saturated Air Pressure(Kg/m) | 0.8--2.0 | ||||

| Humidity range | 35%~98%RH | ||||

| Spray Volume(m/80cm.hr) | 0.5--3.0 | ||||

| PH | Salt | 6.5--7.2 | |||

| Cu(CH COOH) | 3.0--3.2 | ||||

| Exterior / Inner Chamber Material | Imported PVC & PP | ||||

| Systems | Salt Spray Veicle | Air+acid(base)liquid | |||

| Heating | SUS#304 & #316stainless steel heater+taflon | ||||

| Controller | Hydrometer,salinomerer,fog collector,glassbar | ||||

| Other Components | Digital electronic control+S.S.R | ||||

| Savety Devices | Overheating prevention circult-breaker,dehydration and overheating prevention mechanism,breakdown indicator light | ||||

| Power Source[K.W] | AC 1Ψ 220V 60/50Hz | ||||

| 1.1 | 1.5 | 3.5 | |||

| Comply with ASTM B-117, B-287,B-380,JIS D-0201, D-0205, H-8681, Z-2371, K-5400^^ | |||||

Product detail:

In addition to Compound salt mist corrosion test chamber, we are also manufacturing:

Precision Oven Tester, Triple Type Temp. & Humi. Chamber, Temp. & Humi. Control Host, Air Thermal Shock Tester, Liquid Thermal Shock Tester, Walk-in environmental Test Room, Temp. Humi. &Vibration Conbined Test Chamber, Aging Oven Tester, Rain/Spray Test Chamber, Burn-in test equipment, Dust Tester, Steam Aging Tester, Vibration Tester, Tensile Tester, Drop Tester and so on.

Company profile