Basic Info.

Model NO.

HY-Filling

Customized

Customized

Voltage

220V

Composition

Filling Machine

Processing Material

Natural Ingredients

Process

Frozen and Chilled

Chain Distance

114.3mm

Rated Capacity

4000--8000bph

Way of Filling

Isobar Filling

Compressed Air Consumption

0.5nm3h (0.4-0.5MPa)

Suitable Can

Diameter 53-66mm, Height 70-175mm

Filling Pressure

0.25—0.35MPa

Filling Temperature

0-4

Filling Diameter

Ф972

CO2 Consumption

8 Nm3h

Bottle

Can

Speed

1500-30000cph

Color

Stainlerss Steel

Can Volume

500ml, 330ml, 350ml

Brand

Hy-Filling

Control

PLC+Touch Screen

Transport Package

Wooden Case

Specification

300KG

Trademark

HY-Filling

Origin

China

HS Code

8422301090

Production Capacity

4000-8000bph

Product Description

Product Description

We provide the Complete plant turnkey project for can beer production line including:

1.Water Treatment System, (Water Filtration)

2.Beer Filling Machine ,(Filling beer into cans)

3.Blow dryer, (Blow dry water)

4.Flat Convey, (Transport cans)

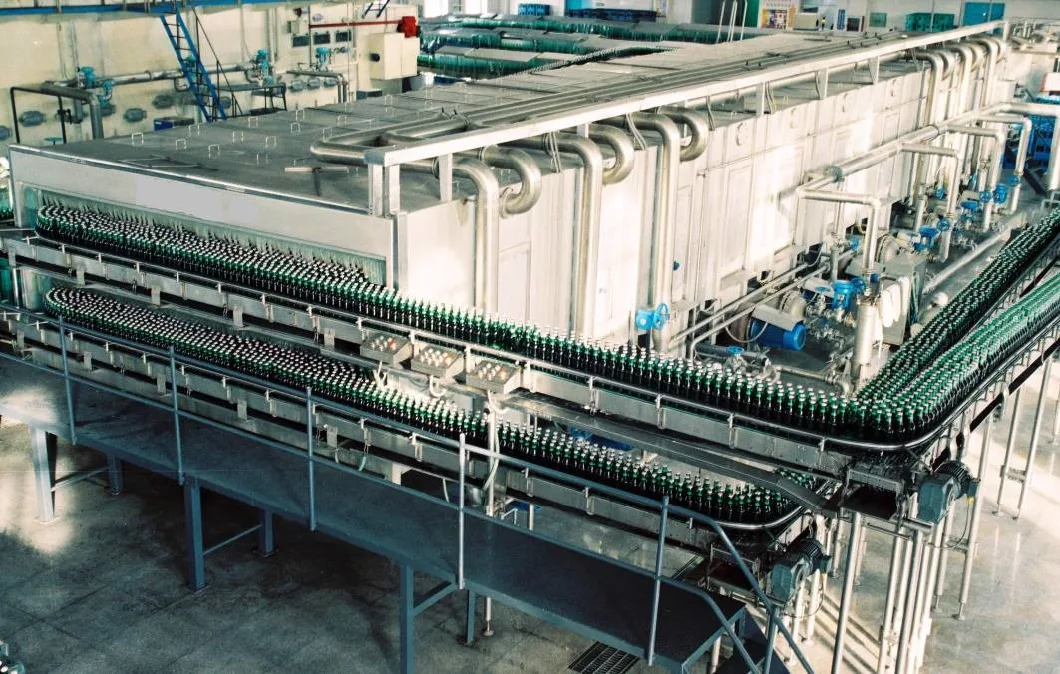

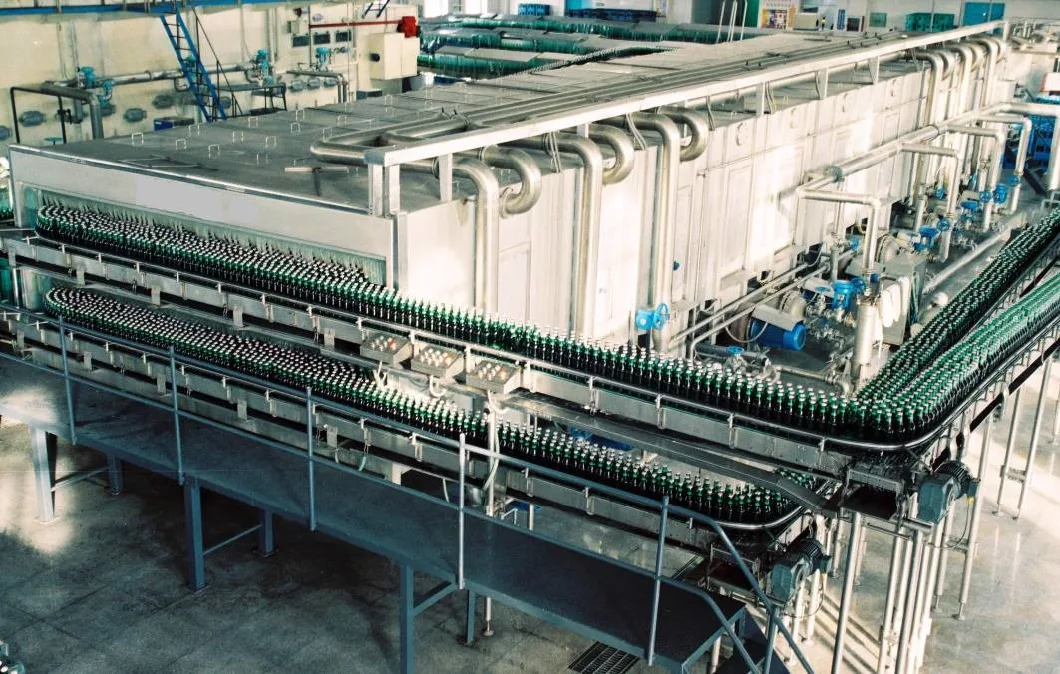

5. Beer Pateurizer Tuneer, (Beer pasteurizing)

6. Ink Jet Printer,(Printing the date on the cans)

7. Shrink Packaging Machine, (Pack the cans by film)

Auxiliary Machines

1.Water treatment

Water treatment is equipped for pure water, mineral water, and water used in beverage drink. It contains RO, natrium filter, ultra

filter, activated carbon filter, ion exchanger, ozone processor etc.

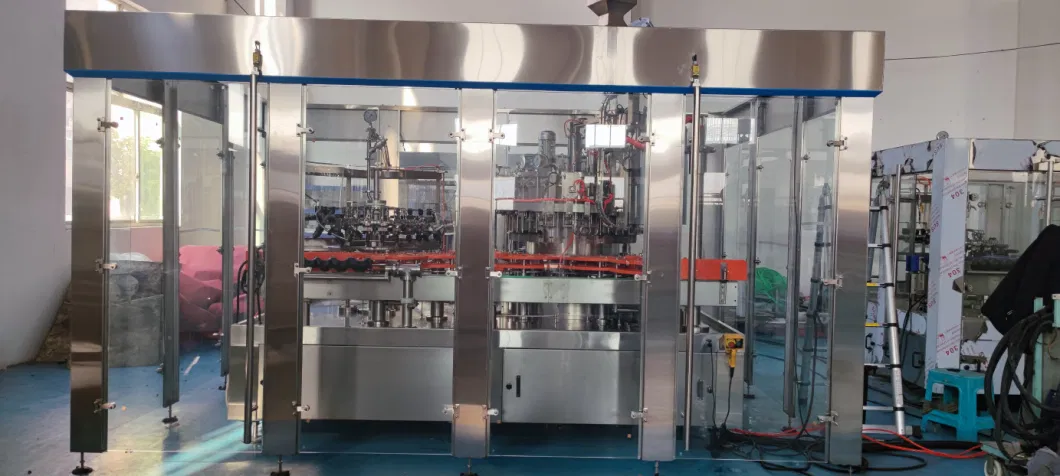

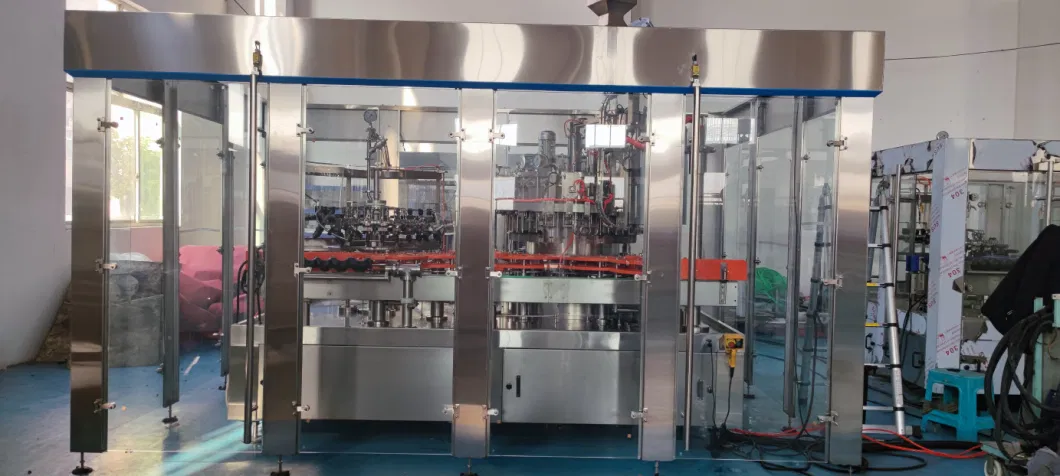

2.Beer Filling Machine

It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

3.Flat Convey

Conveying belt is designed by module, component can be interchanged easily, structure is compact, noise is little, easy assembling and maintaining, have flexibility to combine the bottle type according to the different capacity.

4.Packaging System

Customized: Sleeving Label Machine , Film Shrink-wrapping Machine ,Case Carton Packging machine, Palletizing machine,Date code printer etc.

Beer Pasteuriter Machine

- This machine use double-channel-type continuous chain plate conveyor, running stable, good permeability of water, high strength, and low power consumption. Upper and lower nozzle arrangement is reasonable, small difference in temperature, to ensure the best result of sterilization and min broken bottle.

- Main drive adopts frequency step less speed regulation.

- Main body of this machine use fully open wall structure. It's convenient to open top and both side of the machine for clean, maintain and watch at any time.

- This machine adopts spray tube with rectangular nozzle. Because of its widely square, the nozzles can be adapted to high-volume spray. It has simple structure and hard to be blocked.

- This machine adopts PID temperature automatic control device, high precision of temperature control. And because the small volume of water tank, temperature has short reaction time, it can save energy.

| Technical Parameters: | |

| Way of filling | isobar filling |

| Suitable can | diameter 45~66mm, height 70-135mm |

| Filling pressure | 0.25-0.35Mpa |

| Filling temperature | 0~4ºC |

| Filling diameter | Customized |

We provide the Complete plant turnkey project for can beer production line including:

1.Water Treatment System, (Water Filtration)

2.Beer Filling Machine ,(Filling beer into cans)

3.Blow dryer, (Blow dry water)

4.Flat Convey, (Transport cans)

5. Beer Pateurizer Tuneer, (Beer pasteurizing)

6. Ink Jet Printer,(Printing the date on the cans)

7. Shrink Packaging Machine, (Pack the cans by film)

Auxiliary Machines

1.Water treatment

Water treatment is equipped for pure water, mineral water, and water used in beverage drink. It contains RO, natrium filter, ultra

filter, activated carbon filter, ion exchanger, ozone processor etc.

2.Beer Filling Machine

It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

3.Flat Convey

Conveying belt is designed by module, component can be interchanged easily, structure is compact, noise is little, easy assembling and maintaining, have flexibility to combine the bottle type according to the different capacity.

4.Packaging System

Customized: Sleeving Label Machine , Film Shrink-wrapping Machine ,Case Carton Packging machine, Palletizing machine,Date code printer etc.