Basic Info.

After-Sales Service

Online Video Guidence

Processing Material

Beer Kegs

Application

Beer Kegs

3-Axis CNC Control System

Keyuan

Pneumatic Components

Airtac

Cleaning Machine Feeding Height

970mm

Cleaning Speed

90s/2PCS (Adjustable)

Machine Capacity

80PCS/H

Pickling Pressure

0.5MPa

Total Equipment Power

68.7kw

Machine Dimension

8100*2700*4260mm

Product Name

Beer Keg/Can/Barrel/Drum Production Line Machine

Transport Package

Standard Seaworthy Package

Specification

ISO9001

Trademark

HLT

Origin

Jiangsu, China

HS Code

8480490000

Production Capacity

300sets Per Year

Product Description

Fully Automatic 200L,210.5L Can, Beer/Keg/Drum Production Line

Beer Keg Production Making Machine

Stainless steel kegs produced by our machines

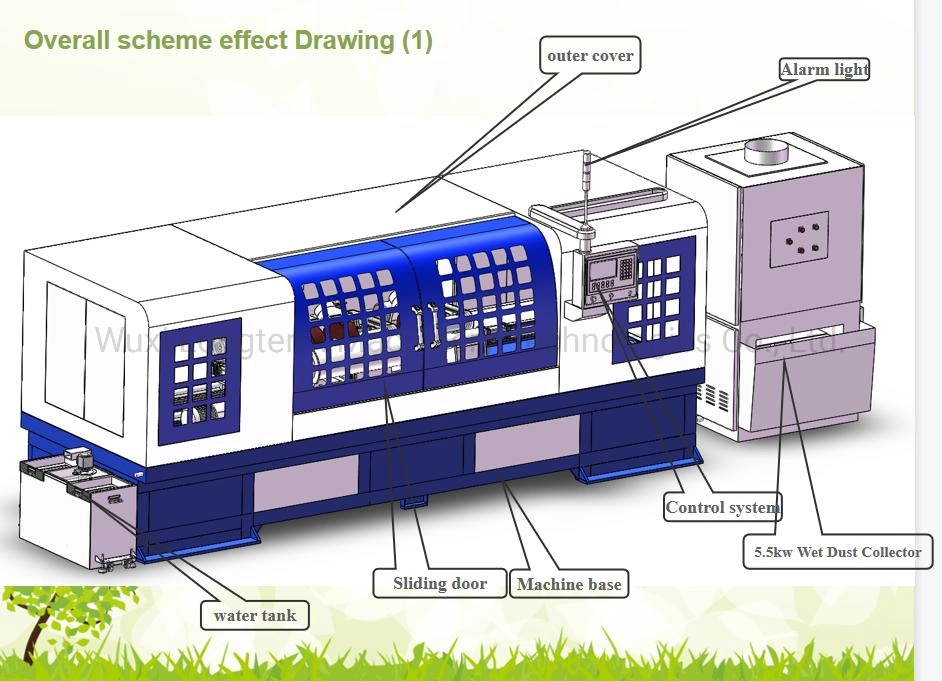

Technical Specification of Cleaning Machine(BJQX-410VII)

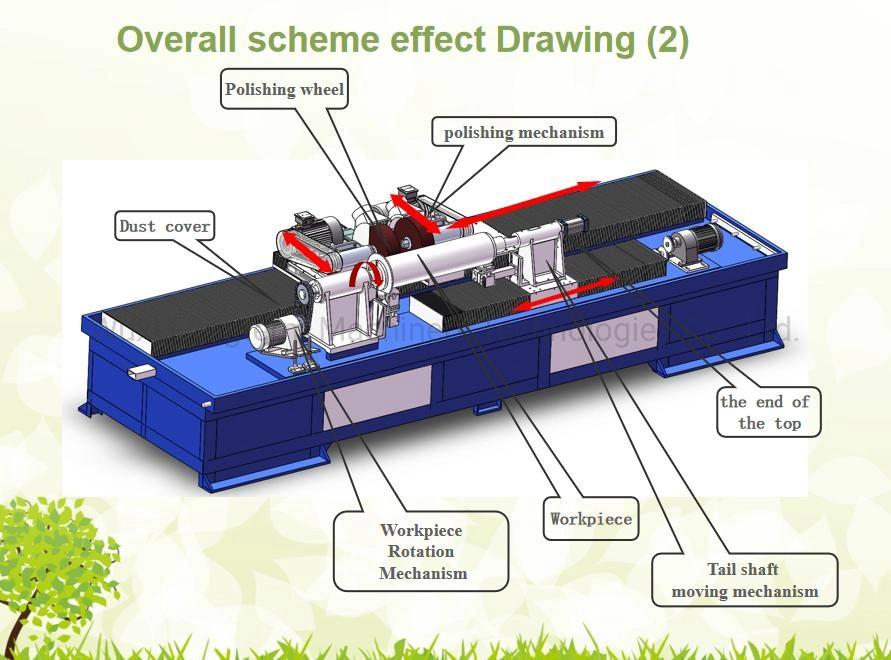

Technical specification for polishing beer keg outer surface

Beer Keg Production Making Machine

Stainless steel kegs produced by our machines

Technical Specification of Cleaning Machine(BJQX-410VII)

- Equipment name:Step-by-step beer keg cleaning machine

- Number of equipment:2 sets

- Cleaning process flow:

→Feeding→Transitioning→Pickling→Rinsing→Rinsing→Passivating→Rinsing→Rinsing→Dry with compressed air→Transitioning→Unloading

- Main cleaning method:

The first station: pickling, the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is pickled without dead ends; the pickling pressure: 0.5MPa, the flow rate: 6m³/H. There is an independent filter water tank. The cleaning solution is filtered and reused.

The second, third, fifth, and sixth stations: rinsing, the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is rinsed without dead angle; rinsing pressure: 0.4MPa, flow: 5m³/H. There is an independent filter water tank. The cleaning solution is filtered and reused.

The fourth station: passivation, the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is pickled without dead ends; the pickling pressure: 0.4MPa, the flow rate: 5m³/H. There is an independent filter water tank. The cleaning solution is filtered and reused.

The seventh station: drying; the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is dried without dead ends; drying pressure: 0.4MPa, compressed air consumption: 90m³/H.

The second, third, fifth, and sixth stations: rinsing, the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is rinsed without dead angle; rinsing pressure: 0.4MPa, flow: 5m³/H. There is an independent filter water tank. The cleaning solution is filtered and reused.

The fourth station: passivation, the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is pickled without dead ends; the pickling pressure: 0.4MPa, the flow rate: 5m³/H. There is an independent filter water tank. The cleaning solution is filtered and reused.

The seventh station: drying; the probe extends into the keg, the rotary nozzle rotates automatically, and the inner wall of the keg is dried without dead ends; drying pressure: 0.4MPa, compressed air consumption: 90m³/H.

- Main technical parameters

- Feeding height:970mm

- Channel size:W*H=420*650mm,dual channel

- Cleaning speed:90S/2pcs (adjustable)

- Machine capacity:80pcs/h

- Cleaning fluid temperature:Normal temperature -60ºC (self-control, adjustable)

- Pickling pressure:0.5MPa,spray flow:6T/h

- Passivating pressure:0.4MPa,spray flow:5T/h

- Rinsing pressure:0.4MPa,spray flow:5T/h

- Effective volume of water tank:0.3m³

- Water pump power:2.2+1.5*5=9.7KW

- Heating power:9KW*6=54KW

- Absorption power:4KW

- Stepper drive power:1.0KW

- Compressed air consumption:100m³/H,pressure 0.4-0.8Mpa

- Total equipment power:68.7KW

- Device dimensions:L *W *H =8100*2700*4260mm

- Equipment structure and principle

It is mainly composed of machine body, circulating water tank and filtration system, probe cleaning system, sliding stepping system, jacking and transplanting system, water mist exhaust treatment system and electrical control system.

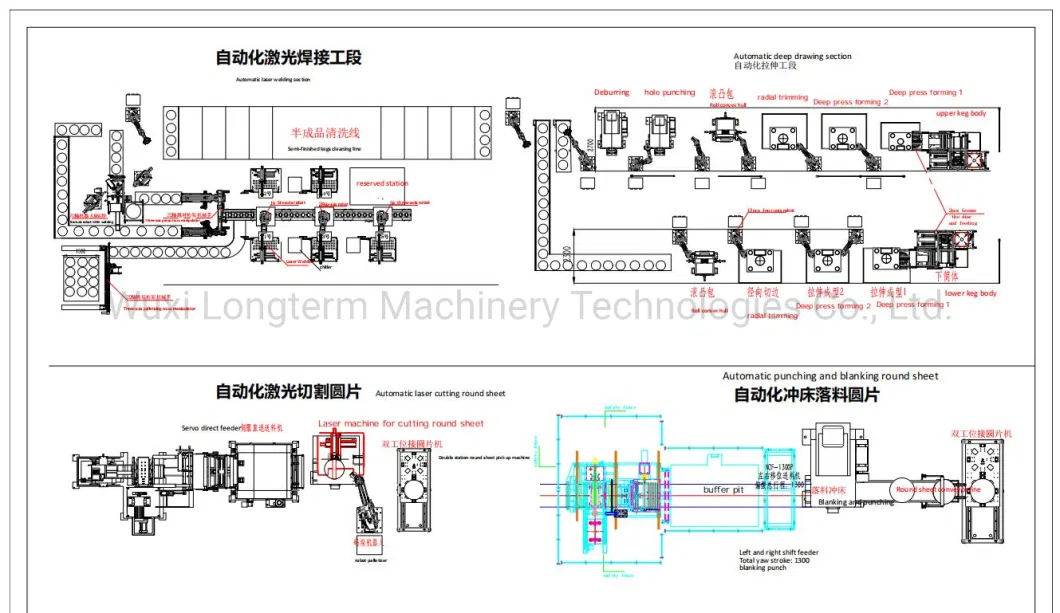

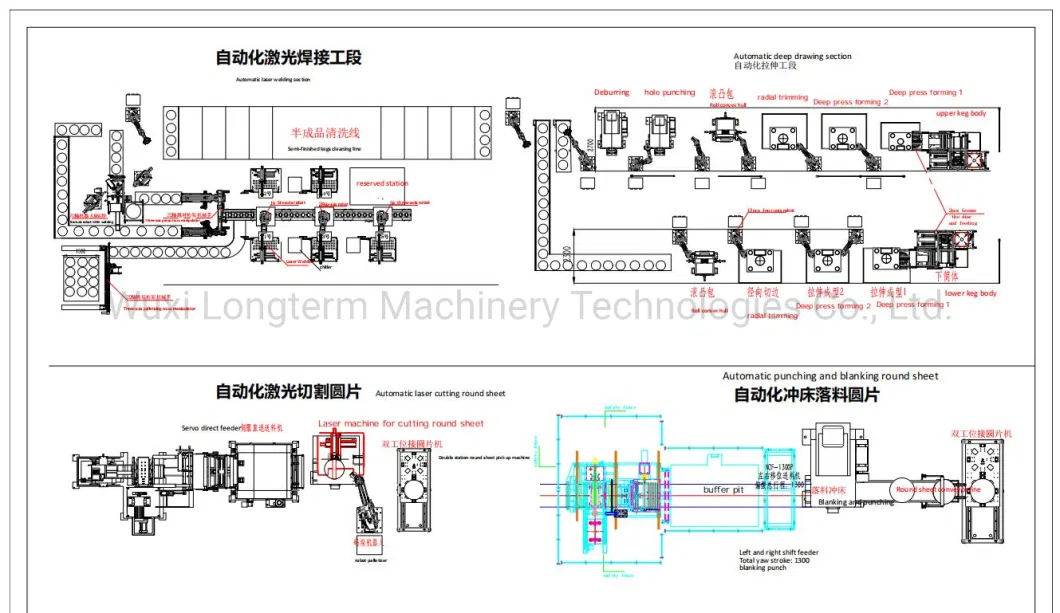

Automatic Blanking,deep drawing machine

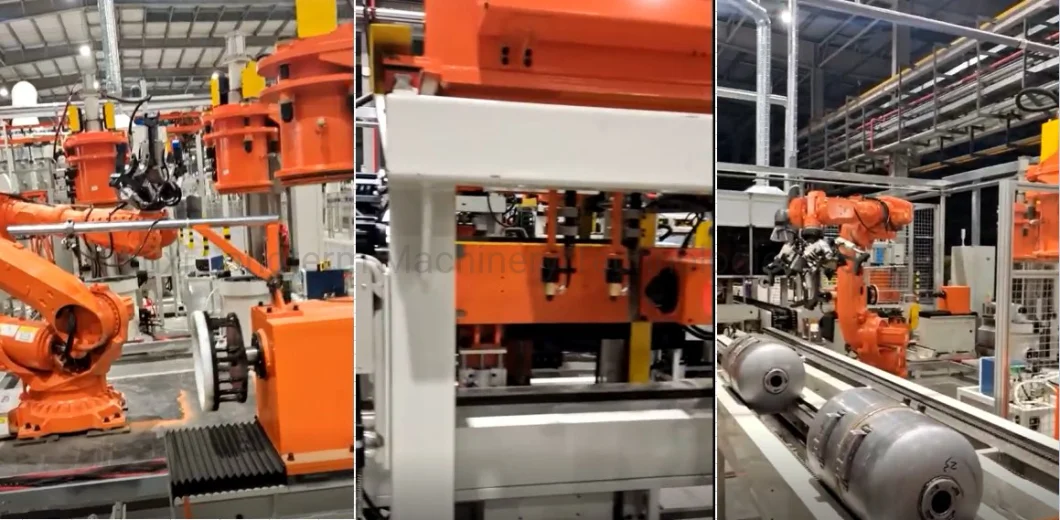

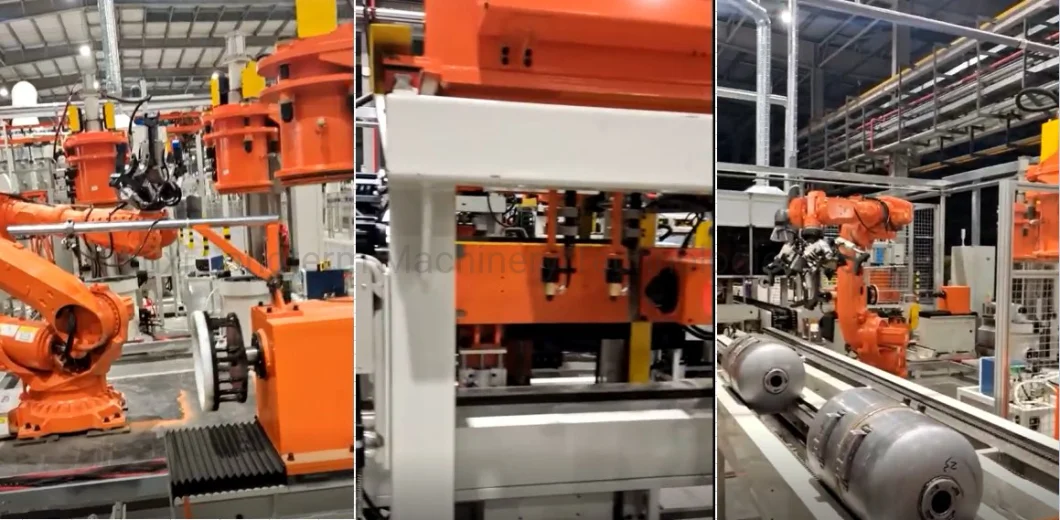

Machine in our client's plant

Automatic welding line

Six-axis MAG welding robot with one-way valve and upper keg body

Three-axis palletizing truss manipulator

Three-axis laser welding equipment

Six-axis handling robot

Triaxial group truss manipulator

One-way valve and upper keg body positioner

Upper keg body feeding conveyor line and positioning

Automatic Blanking,deep drawing machine

Machine in our client's plant

Automatic welding line

Six-axis MAG welding robot with one-way valve and upper keg body

Three-axis palletizing truss manipulator

Three-axis laser welding equipment

Six-axis handling robot

Triaxial group truss manipulator

One-way valve and upper keg body positioner

Upper keg body feeding conveyor line and positioning

Machine layout

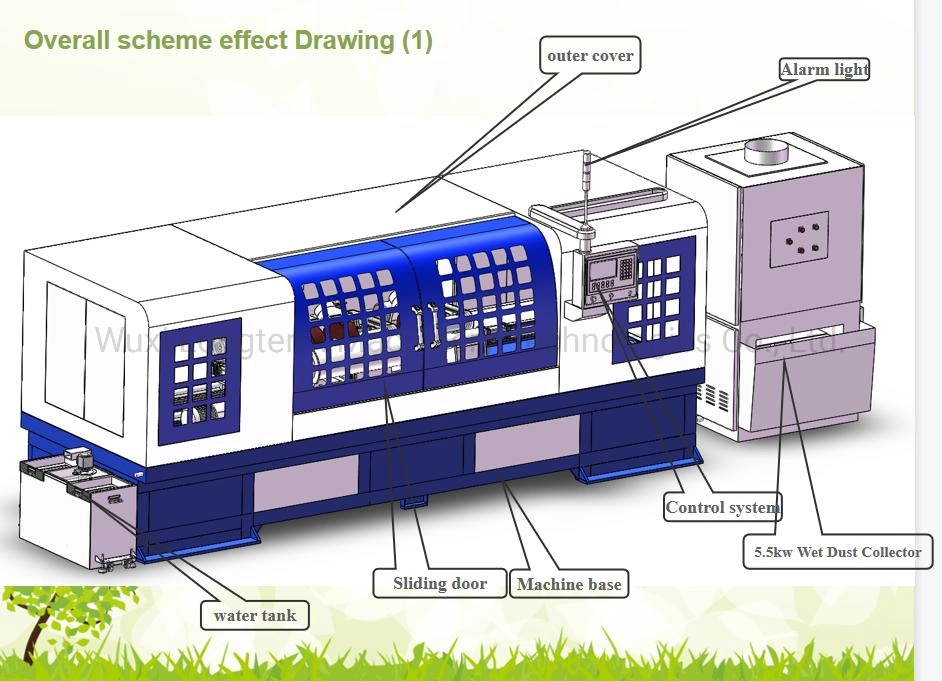

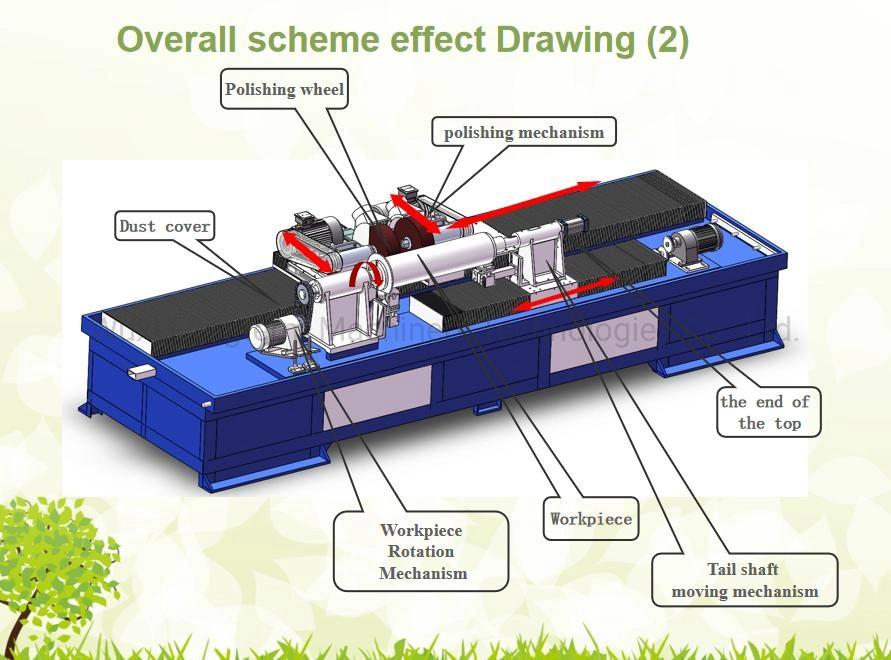

Technical specification for polishing beer keg outer surface

Machine Description

This equipment is mainly for the surface polishing of beer kegs. The equipment uses a cylinder to clamp both ends of the kegs tightly. The outer surface is polished in sequence by two sets of polishing wheels (consumables are selected according to the polishing process). The left and right movement of the grinding mechanism and the wear of the polishing wheel can be automatically fed and compensated by the servo system. The equipment automatically completes the polishing process, and the surface effect is uniform and meticulous, and the operation is simple. The whole machine is equipped with a ring protection cover, and is equipped with a dust collector, which is safe and environmentally friendly.

This equipment is mainly for the surface polishing of beer kegs. The equipment uses a cylinder to clamp both ends of the kegs tightly. The outer surface is polished in sequence by two sets of polishing wheels (consumables are selected according to the polishing process). The left and right movement of the grinding mechanism and the wear of the polishing wheel can be automatically fed and compensated by the servo system. The equipment automatically completes the polishing process, and the surface effect is uniform and meticulous, and the operation is simple. The whole machine is equipped with a ring protection cover, and is equipped with a dust collector, which is safe and environmentally friendly.

| Main configuration | ||

| Name | Brand/Specification | QTY(set) |

| Frame | Homemade 6000*1600*500 | 1 |

| Sheet metal | Homemade 6000*1700*1200 | 1 |

| Workpiece rotating power head | Bearing seat, spindle | 1 |

| Polishing power head | Bearing seat, spindle, motor board, pulley | 2 |

| The end of the top | 63*150 Cylinder, Tailstock | 1 |

| Servo motor + drive | Delta/1.5KW | 1 |

| Servo motor + drive | Delta/0.75KW | 2 |

| Planetary reducer | Newgate/120 Model 1:10 | 1 |

| Bearing | HRB | 1 lot |

| Screw rod | Homemade 32*450 | 2 |

| Dust cover | Homemade 500*5500 | 2 |

| Dust cover | Homemade 400*1200 | 2 |

| Rails, sliders | 30*800 | 4 |

| Rails, sliders | 40*5500 | 2 |

| Rails, sliders | 40*1200 | 2 |

| Main motor | Mindong, Fujian/4KW | 2 |

| Gear reducer | Feibao/1.5KW | 1 |

| Gear reducer | Feibao/0.75KW | 1 |

| 3-axis CNC control system | Keyuan | 1 |

| Electrical appliances | Shihlin Electric | 1 lot |

| Pneumatic Components | AirTAC | 1 lot |

| Inverter | Zheng Xuan | 1 |

| 1 | Voltage | 480V-60HZ | 2 | Equipment installation size | 6000*2000*2000 |

| 3 | Total power | 13.25kw | 4 | Polishing Wheel Specifications | φ350x100*φ32 Inner hole mm |

| 5 | Polished main motor | 4kw*2 | 6 | One-time processing product | 1 piece |

| 7 | Workpiece rotation motor | 1.5kw | 8 | Spindle speed | 2300r/min |

| 9 | Tail shaft moving motor | 0.75KW | 10 | Machine weight | About 2200kg |

| 11 | Polishing wheel feed servo | 0.75kw*2 | 12 | Polishing wheel moves left and right servo | 1.5kw |

| 13 | Air pressure | 0.5-0.8MPa | 14 | Scope of workpiece | Diameter:50-500 Length: 200-300mm |

| Numbers of workers for fully-auto beer keg prodution line | |||

| NO. | Production Process | No. of workers | Remark |

| 1 | Round sheet blanking | 1 | |

| 2 | Automatic deep drawing | 1 | |

| 3 | Cleaning line | 0 | |

| 4 | Auto keg body welding | 1 | |

| 5 | Semi-auto top&bottom skirt welding | 3 | |

| 6 | Air leakage | 1 | |

| 7 | Passivation | 2 | |

| 8 | Outer polishing | 8 | According to 150 kegs per hour, it requires about 25 sets machine |

| 9 | Top skirt welding line | 7 | |

| 10 | Bottom skirt welding line | 5 | |

Company Introdution

Wuxi Longterm Machinery Technologies Co.,Ltd is the professional manufacturer of steel drum, beer kegs, steel cans production line machienry,such as auto-welding equipment (MIG, TIG, MAG, PAW) and automatic welding system integration, as well as related equipment. Due to highly automatic, simple operation, welding strength and service life with the same stainless steel and plate, is widely used in aerospace.

if you have any inquiry,welcome to inquiry us!

FAQ

To enable me send you offer for correct machines, please tell me following details:

A: Technical drawing of beer kegs

B: Size range of beer kegs you want to manufacture

C: What's the capacity per shift/day?