Basic Info.

Model NO.

ANG-H

Condition

New

Heating Method

Electricity, LNG, LPG, Oil

Voltage

380V/ 460V

Design Service

Available

Installation Service

Available

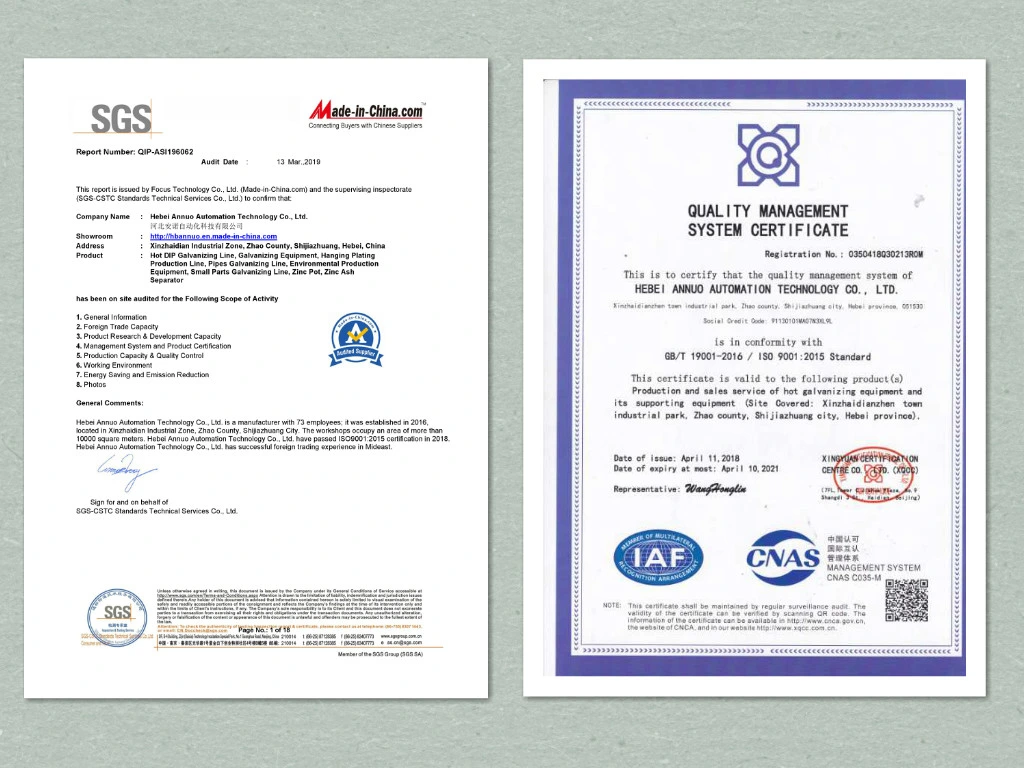

Certificate

CE ISO9001 SGS

ODM

Available

OEM

Available

Zinc Fume Enclosure

Fixed Enclosure,Movable Enclosure,Tunnel Enclosure

Pickling Room

Fully Enclosed

Pickling Tank

PP, Granite, Steel

Transport Package

as Required

Specification

customized

Trademark

ANNUO

Origin

Hebei, China

HS Code

8543300000

Production Capacity

20 Sets/Year

Product Description

Features of Automatic Hot Dip Galvanizing Production Line

1. Fully enclosed pretreatment

2. Fully enclosed drying

3. Fully enclosed hot dip galvanizing

4. Near zero emissions to the atmosphere

5. Waste heat is recycled and re-used

6. Water recycled within the plant

7. Energy consumption is significantly reduced

8. Fully automatic handling equipment

9. Significantly improved workplace safety

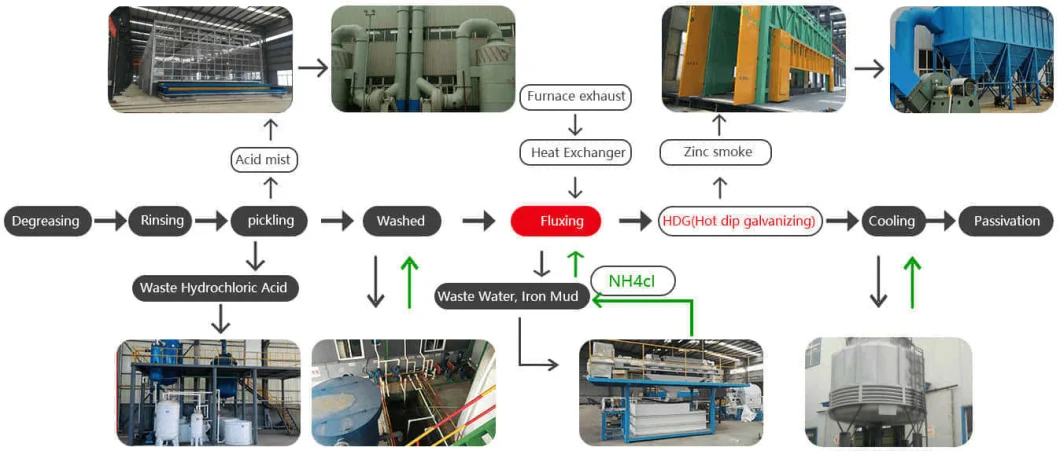

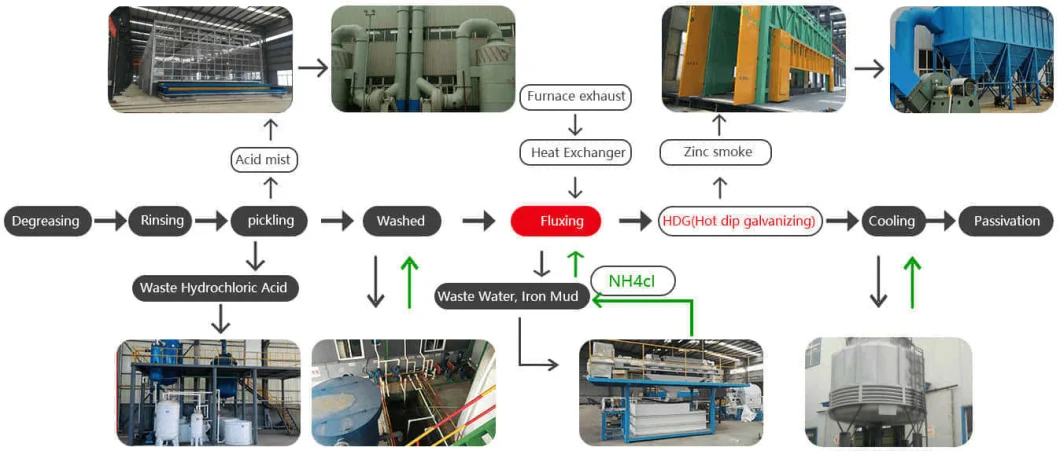

Technical Process for Galvanizing line

Black workpiece preparation--- Degreasing --- Rinsing --- Pickling --- Rinsing --- Fluxing--- Drying --- Galvanizing ---Cooling --- Passivation--- Finished products check and packing

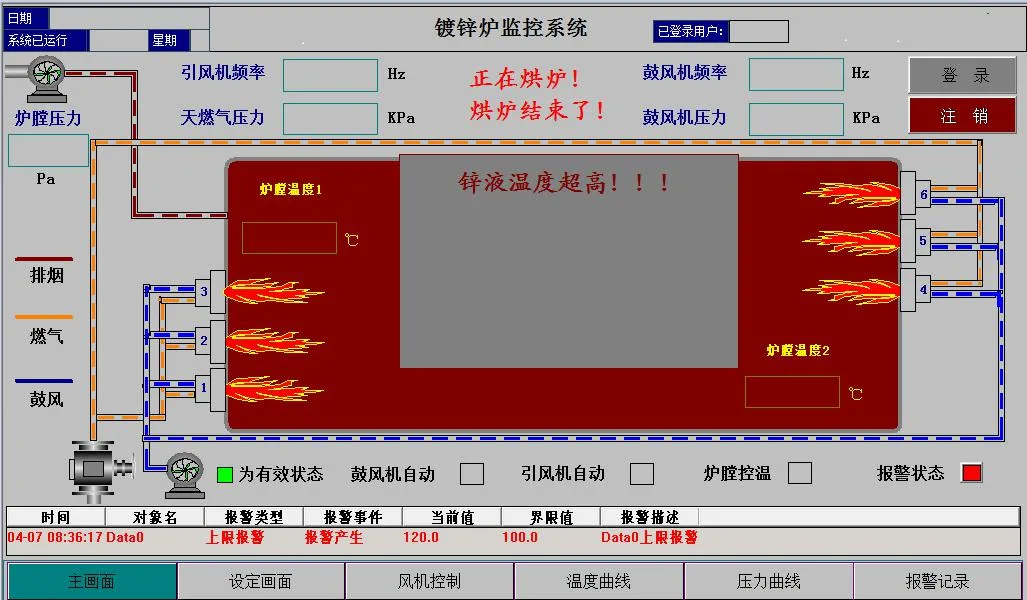

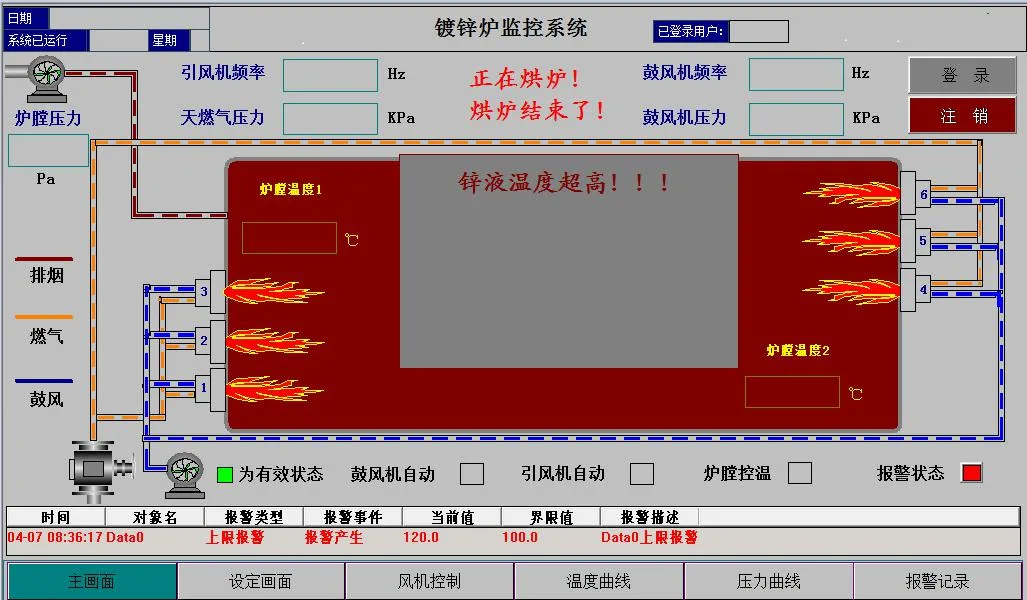

Galvanizing Furnace

Zinc kettle

Pretreatment system

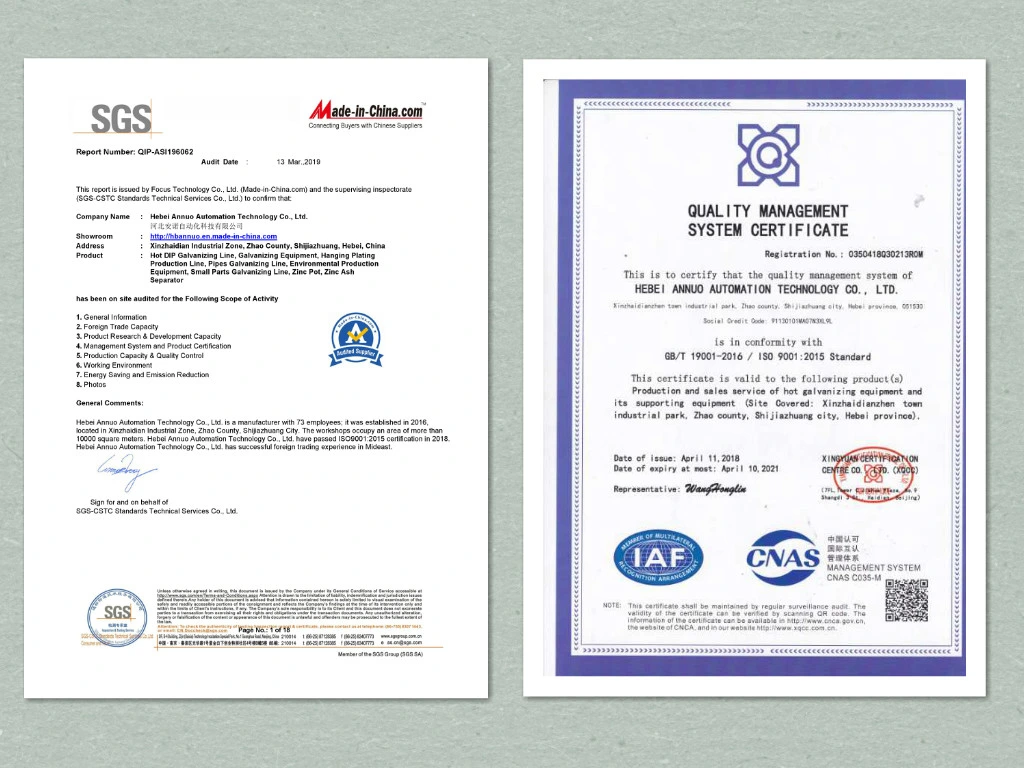

ISO9001 & SGS Certificates:

CE CERTIFICATES

For detailed information pls feel free to contact us, thanks.

1. Fully enclosed pretreatment

2. Fully enclosed drying

3. Fully enclosed hot dip galvanizing

4. Near zero emissions to the atmosphere

5. Waste heat is recycled and re-used

6. Water recycled within the plant

7. Energy consumption is significantly reduced

8. Fully automatic handling equipment

9. Significantly improved workplace safety

Technical Process for Galvanizing line

Black workpiece preparation--- Degreasing --- Rinsing --- Pickling --- Rinsing --- Fluxing--- Drying --- Galvanizing ---Cooling --- Passivation--- Finished products check and packing

Galvanizing Furnace

Zinc kettle

Pretreatment system

ISO9001 & SGS Certificates:

CE CERTIFICATES

For detailed information pls feel free to contact us, thanks.