Basic Info.

Model NO.

4.8mm-21.6mm

Tensile Strengh

1570MPa, 1670MPa, 1770MPa, 1860MPa

Cross Sectional Shape

Circular

Surface

Spiral Rib

Application

to Manufacture Prestressed Concrete Products

Export Packing

Baling Strip, Plastic Cover, PP Packing Cloth

Weight

0.8-2.5mt Per Coil

Transport Package

Standard Export Packing

Specification

4.0mm, 5.0mm, 6.0mm, 7.0mm

Trademark

Silvery Dragon or as customer required

Origin

China

HS Code

7326201000

Production Capacity

400, 000mt/Year

Product Description

Spiral Rib PC Wire

Normal Diameter: 4.0mm-8.0mm

Tensile Strength: 1470, 1570, 1670, 1670, 1770, 1860Mpa

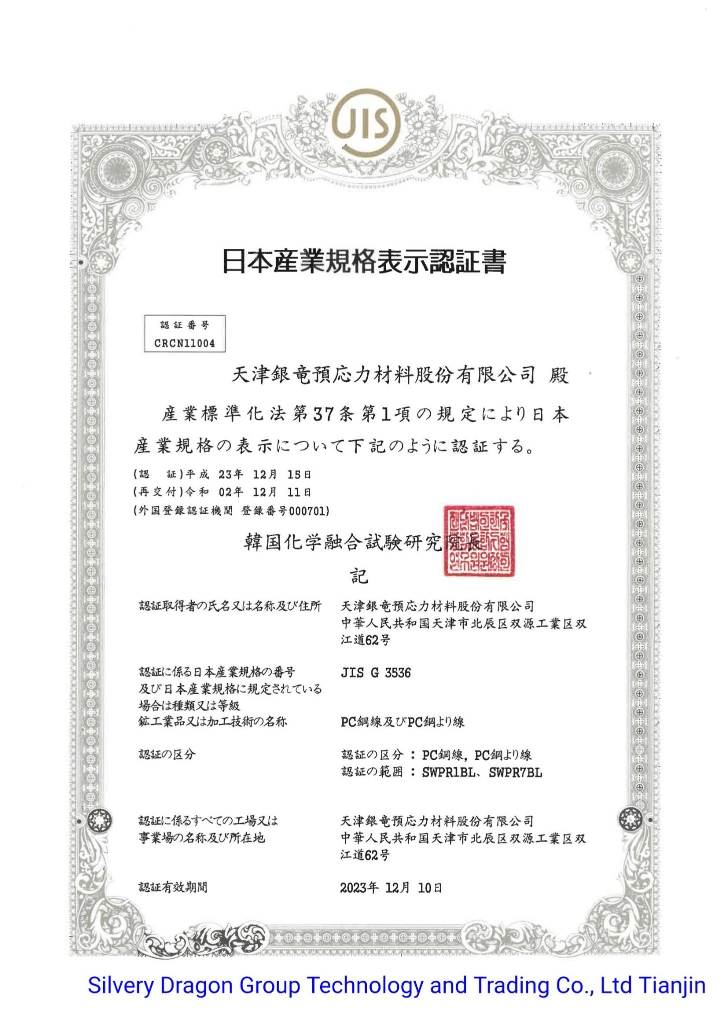

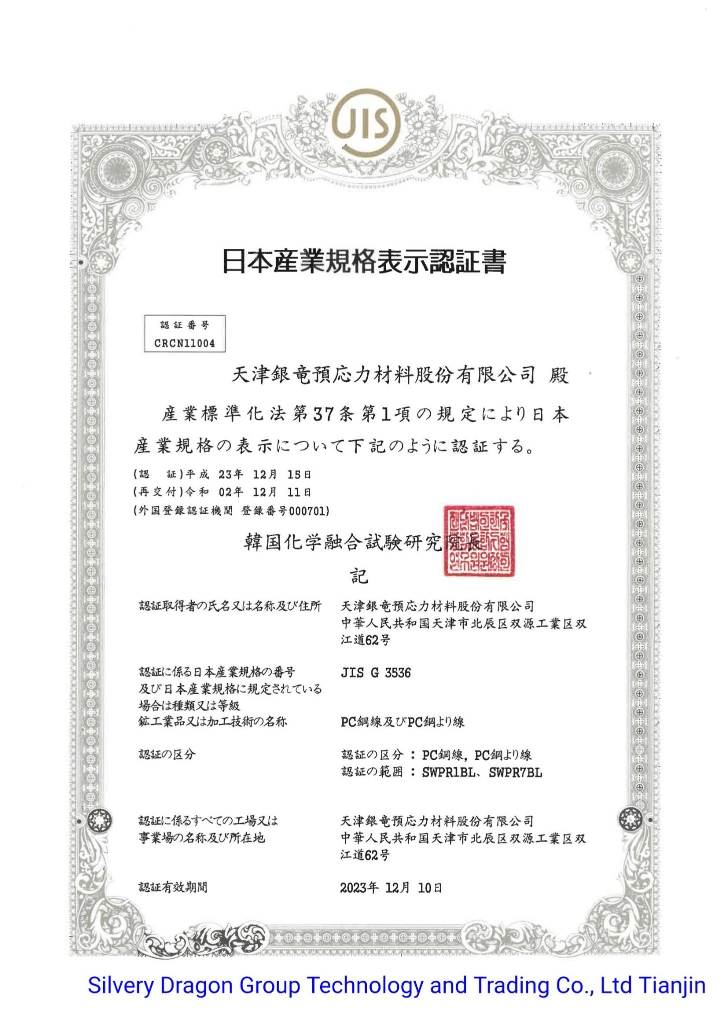

Standard: ASTM881, EN10138-2, BS5896, JISG3536, AS/NZS4672-1, GB/T5223

Surface Finishing: Spiral ribs

Coils weight: 0.8-2.5 MT / Coils

Spiral rib wire is invented by Silvery Dragon, representing China's advanced R&D achievements; it services in China and dedicates to world. The product is characteristic of 3 to 6 spiral ribs through spiral deforming drawing on the surface of wire, increasing the bond ability with concrete, thus improving the overall performance of pre-stressed concrete products and increasing the service life. Silvery Dragon holds the advanced product technology of uniform spiral drawing, internal stress relief and anti-corrosion which meets Germany, USA, France and other international anti-corrosion requirements.

Spiral rib wire is produced by the selected high quality carbon wire rod and refined by strict surface treatment, multi-times drawing and stabilization processing automatic production line. The products range from φ3.8 to 12.0mm in various specifications and different strength levels for customers' choice. It is especially suitable for the production of railway sleeper, electrical pole, roof board, beam body, etc.

When the spiral rib wire was introduced to the international markets firstly, there was no specification for this kind of wire among all the international standards. Normally, the technical specifications as for the tensile strength, yield strength, corrosion, relaxation confirmed to standards recognized by the customers; and the wire surface shape confirmed to Chinese standard GB/T5223. Now more and more foreign customers adopt directly GB/T5223.

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for OEM/ODM Supplier China Swrh77b Helical Ribs High Tensile PC Wire, All products and solutions arrive with high quality and fantastic after-sales expert services. Market-oriented and customer-oriented are what we now have been being immediately after. Sincerely look ahead to Win-Win cooperation !

Key parameter & reference standards of Indented PC wire

Photographs of the goods after load

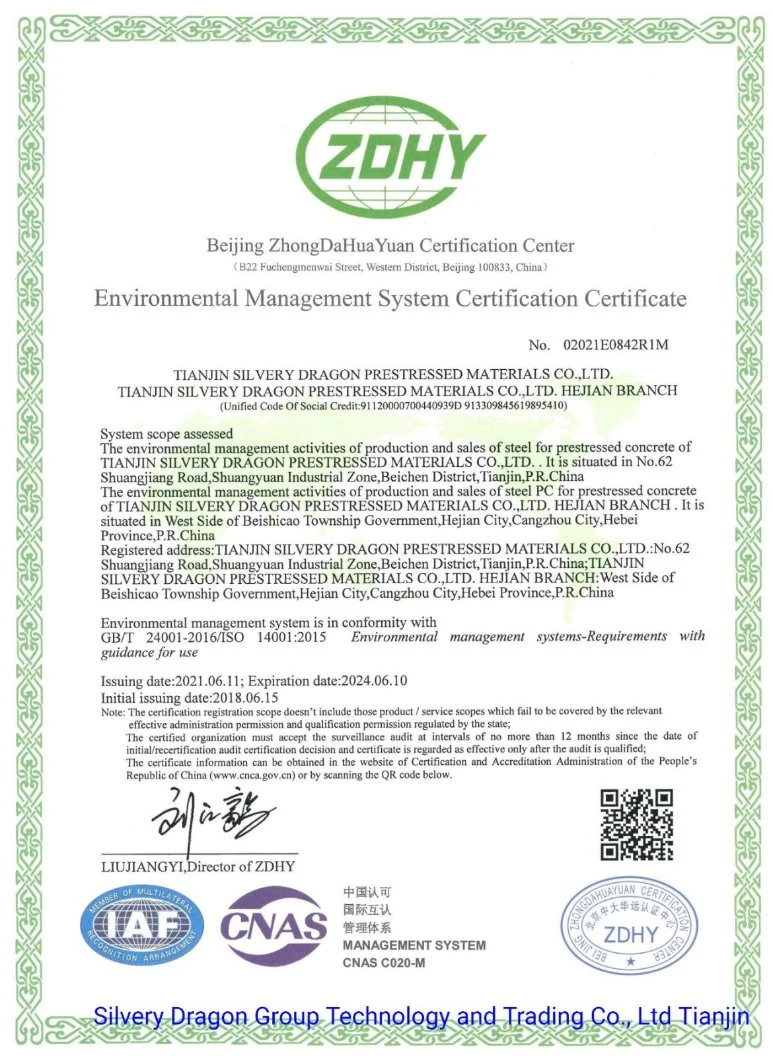

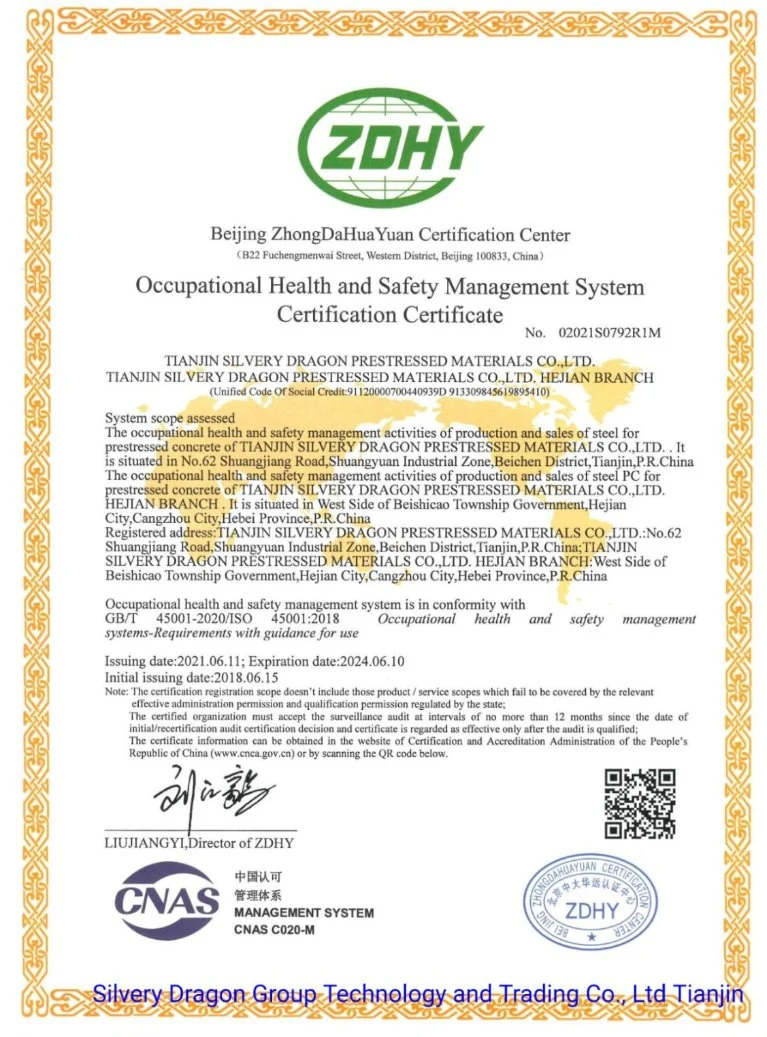

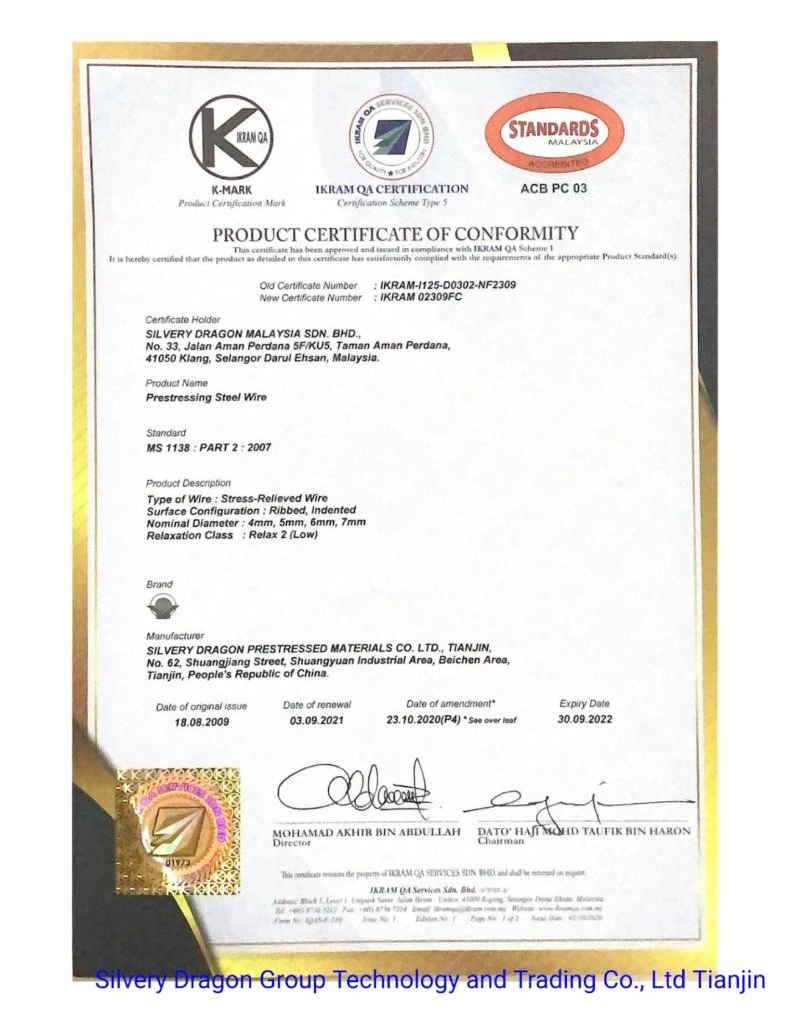

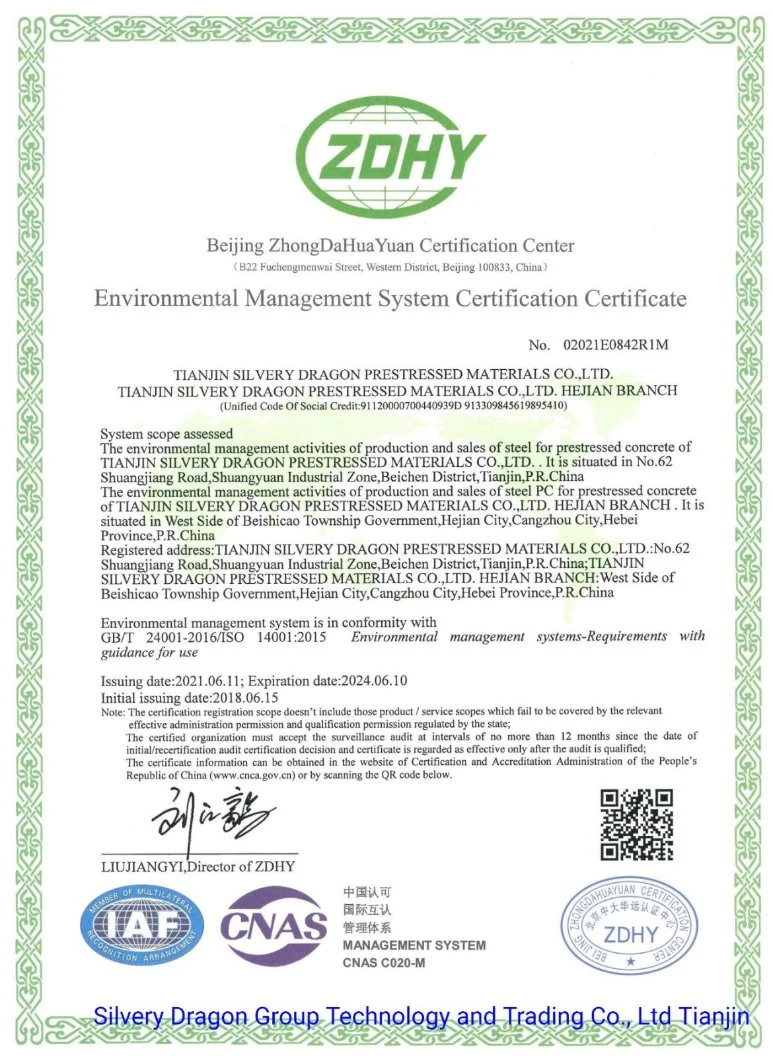

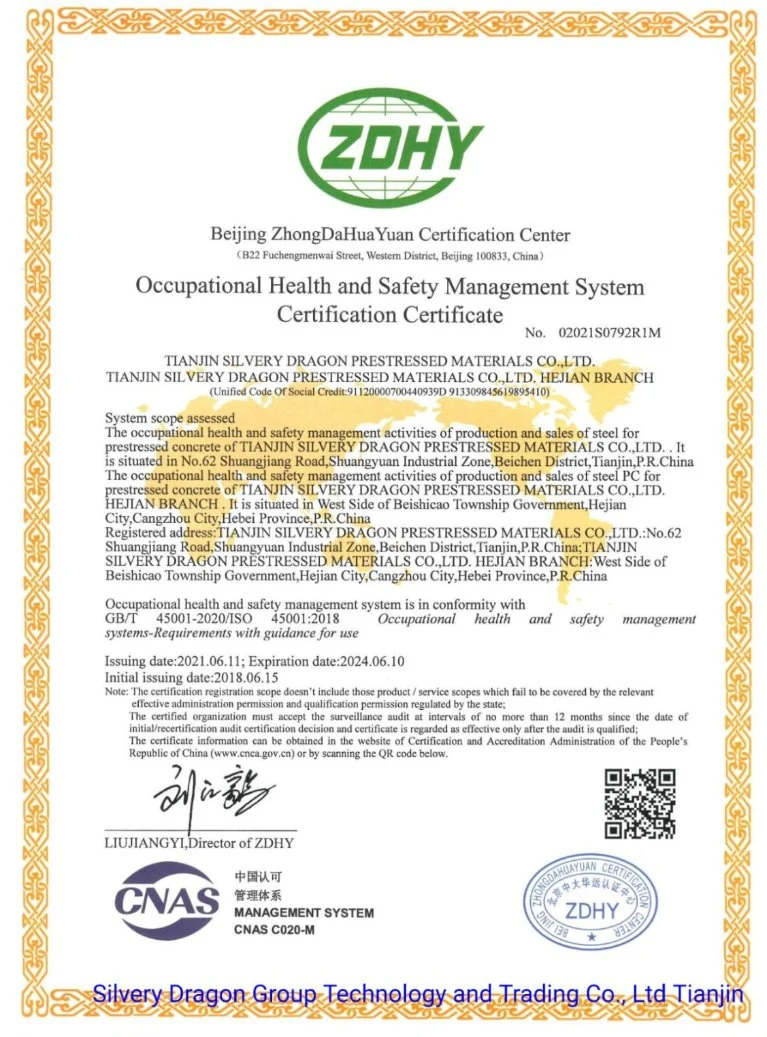

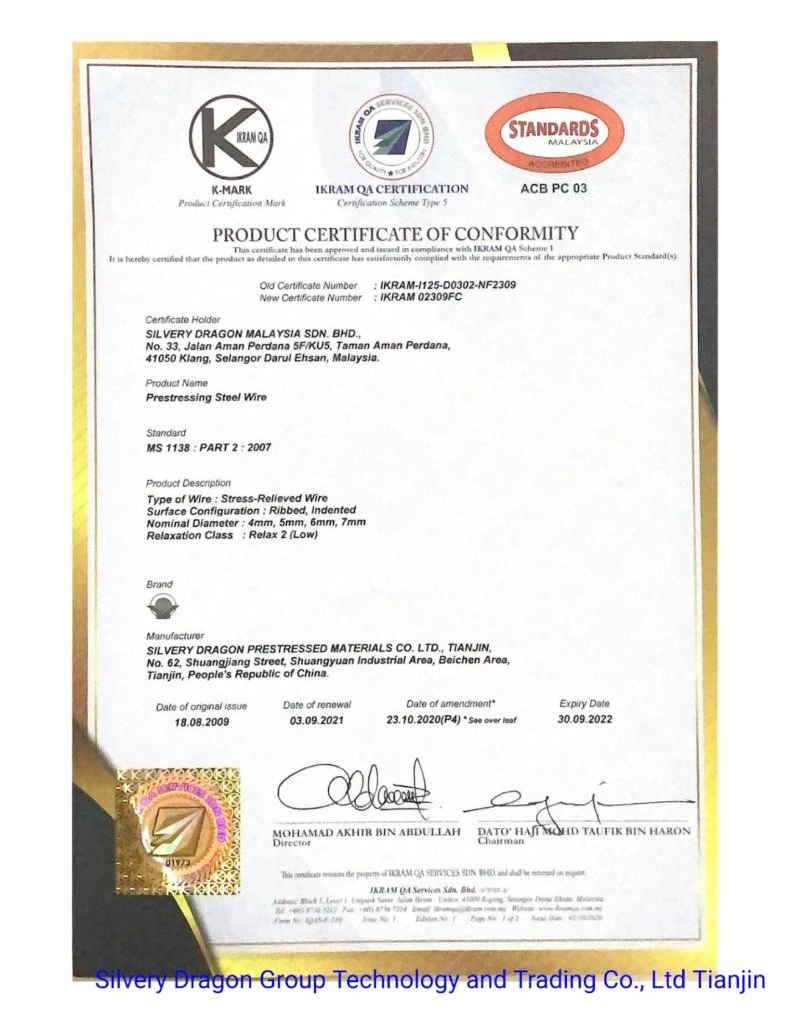

Certificate

Normal Diameter: 4.0mm-8.0mm

Tensile Strength: 1470, 1570, 1670, 1670, 1770, 1860Mpa

Standard: ASTM881, EN10138-2, BS5896, JISG3536, AS/NZS4672-1, GB/T5223

Surface Finishing: Spiral ribs

Coils weight: 0.8-2.5 MT / Coils

Spiral rib wire is invented by Silvery Dragon, representing China's advanced R&D achievements; it services in China and dedicates to world. The product is characteristic of 3 to 6 spiral ribs through spiral deforming drawing on the surface of wire, increasing the bond ability with concrete, thus improving the overall performance of pre-stressed concrete products and increasing the service life. Silvery Dragon holds the advanced product technology of uniform spiral drawing, internal stress relief and anti-corrosion which meets Germany, USA, France and other international anti-corrosion requirements.

Spiral rib wire is produced by the selected high quality carbon wire rod and refined by strict surface treatment, multi-times drawing and stabilization processing automatic production line. The products range from φ3.8 to 12.0mm in various specifications and different strength levels for customers' choice. It is especially suitable for the production of railway sleeper, electrical pole, roof board, beam body, etc.

When the spiral rib wire was introduced to the international markets firstly, there was no specification for this kind of wire among all the international standards. Normally, the technical specifications as for the tensile strength, yield strength, corrosion, relaxation confirmed to standards recognized by the customers; and the wire surface shape confirmed to Chinese standard GB/T5223. Now more and more foreign customers adopt directly GB/T5223.

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for OEM/ODM Supplier China Swrh77b Helical Ribs High Tensile PC Wire, All products and solutions arrive with high quality and fantastic after-sales expert services. Market-oriented and customer-oriented are what we now have been being immediately after. Sincerely look ahead to Win-Win cooperation !

Key parameter & reference standards of Indented PC wire

| Appearance | Nominal Dia.(mm) | Tensile Strength(MPa) | Relaxation(1000h) | Standards |

| Spiral ribs | 3.8, 4.0, 5.0, 6.0, 6.25, 7.0, 7.5, 8.0, 9.0, 9.4, 9.5, 10.0, 10.5, 12.0 | 1470,1570,1670,1770,1860 | Normal relaxation≤8% Low relaxation≤2.5% | GB/T5223, BS5896, JISG3536, EN10138 |

| 5.03, 5.32,5.5 | 1570,1700,1770 | ASTMA881, AS/NZS4672.1 | ||

| 4.88, 4.98, 6.35, 7.01 | 1620,1655,1725 | ASTMA421 |

Photographs of the goods after load

Certificate