Basic Info.

Condition

New

Transport Package

Bulk

Specification

hanging

Trademark

annuo

Origin

Hebei

Production Capacity

20set/ Year

Product Description

general (batch) hot dip galvanizing plants

We can design and commission general (batch) hot dip galvanizing plants, as well as automatic pipe or spin galvanizing plants.

Our product range includes standard configuration plants, inclusive of the hot section (galvanizing furnace and dryer) and the chemical pretreatment area (degreasing-pickling-fluxing). However, we can also supply more comprehensive solutions, enriched by automation in lifting and transport of products of all sizes and categories.

Each project will be customized to the specific needs of the Customer and analyzed down to the tiniest detail, including support on the analysis of financial viability of the investment.

Our technicians will build a project that would be entirely tailored to the specifics of your company. This includes the capacity to design an installation from a green field scenario or adapt to an existing industrial building (full revamping of existing installations).

We also offer design and technical support for specific product ranges, such as pipes, wireless and power towers, poles, road barriers and many others which entail seamless integration between production and hot dip galvanizing stages, sometimes assisting with product handling outside of the specific galvanizing context.

An industrial hot dip galvanizing installation by annuo is completely devoid of bottlenecks, so that the entire process flows efficiently, reducing operating costs and maximizing return on investment.

Our Company's Advantages:

Strong research team including 50 experts, professors, senior engineers and other high-tech R&D specialists.

Established strategic partnership with famous universities and research institues in China and abroad.

World-Class leading hot-dip galvanizing techniques.

Latest concept of factory and production line design.

Capability of new equipment invention and development.

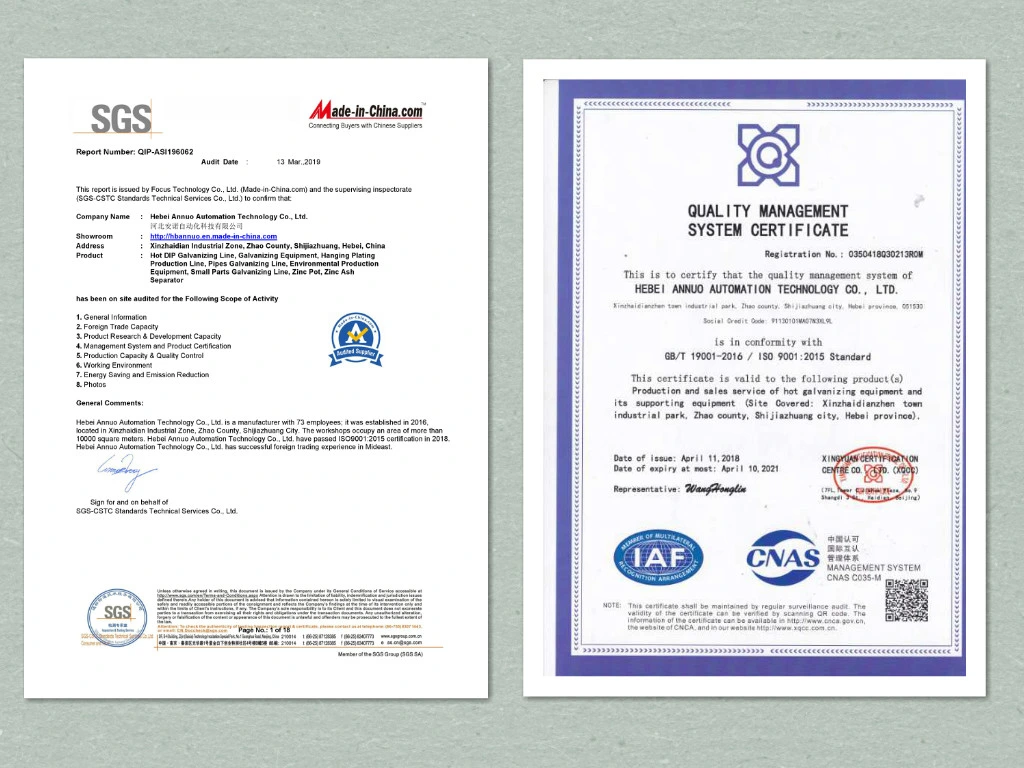

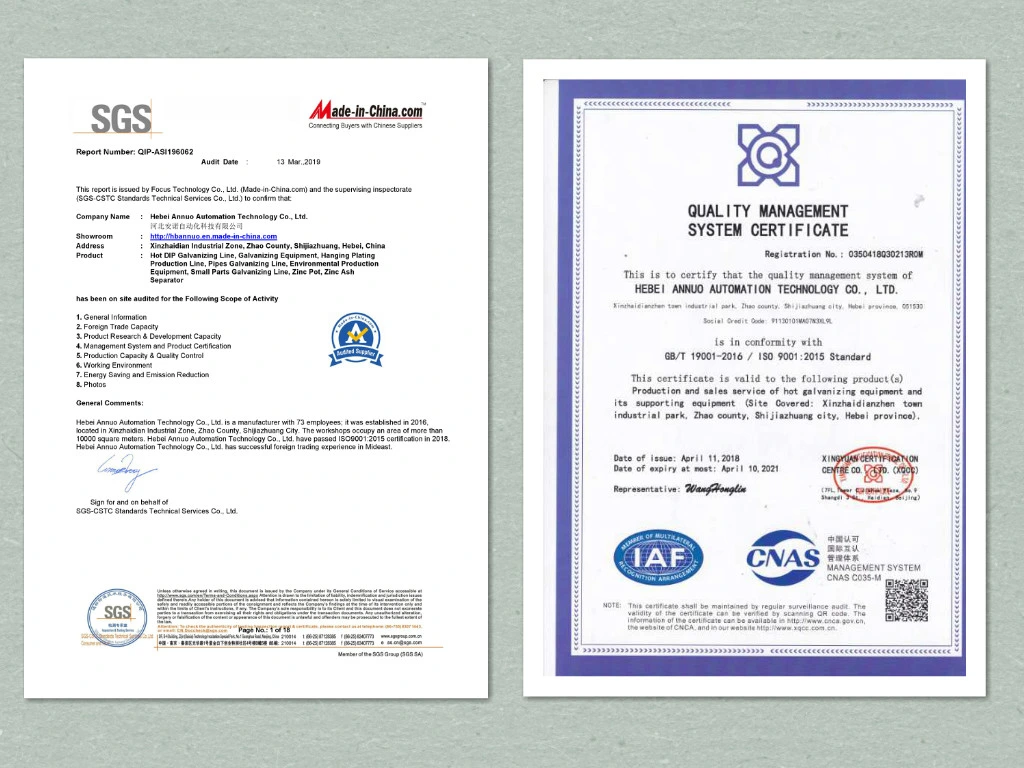

Certificates:

All products are CE Authentication

For detailed information pls feel free to contact us, thanks.

we can offer :

pre-treatment tank

fully enclosed pickling room

zinc kettle

molten zinc pump

fluxing tank iron removal machine - flux regeneration system

acid mist collection - pp scrubbing tower

wast acid storage and treatment

Bag house fliter for zinc white fume extraction

and so on

We can design and commission general (batch) hot dip galvanizing plants, as well as automatic pipe or spin galvanizing plants.

Our product range includes standard configuration plants, inclusive of the hot section (galvanizing furnace and dryer) and the chemical pretreatment area (degreasing-pickling-fluxing). However, we can also supply more comprehensive solutions, enriched by automation in lifting and transport of products of all sizes and categories.

Each project will be customized to the specific needs of the Customer and analyzed down to the tiniest detail, including support on the analysis of financial viability of the investment.

Our technicians will build a project that would be entirely tailored to the specifics of your company. This includes the capacity to design an installation from a green field scenario or adapt to an existing industrial building (full revamping of existing installations).

We also offer design and technical support for specific product ranges, such as pipes, wireless and power towers, poles, road barriers and many others which entail seamless integration between production and hot dip galvanizing stages, sometimes assisting with product handling outside of the specific galvanizing context.

An industrial hot dip galvanizing installation by annuo is completely devoid of bottlenecks, so that the entire process flows efficiently, reducing operating costs and maximizing return on investment.

Our Company's Advantages:

- Technical advantages

Strong research team including 50 experts, professors, senior engineers and other high-tech R&D specialists.

Established strategic partnership with famous universities and research institues in China and abroad.

World-Class leading hot-dip galvanizing techniques.

Latest concept of factory and production line design.

Capability of new equipment invention and development.

- Planning and design advantages of whole production line

- Quality advantages

- Project construction advantages

- Service advantages

Certificates:

All products are CE Authentication

For detailed information pls feel free to contact us, thanks.

we can offer :

pre-treatment tank

fully enclosed pickling room

zinc kettle

molten zinc pump

fluxing tank iron removal machine - flux regeneration system

acid mist collection - pp scrubbing tower

wast acid storage and treatment

Bag house fliter for zinc white fume extraction

and so on