Basic Info.

Model NO.

CGL001

Certification

ISO, CE

Material

Steel

Energy Sources

Water, Electricity, Nature Gas

Strip Thickness

0.2-2.5mm

Strip Width

1000-1500mm (Max)

Transport Package

Standard Seaworthy Package

Origin

China

Product Description

The steel plate that is about to be cleaned is immersed into the dissolved zinc pot after reduction annealing to make its surface adhere to a layer of zinc or zinc aluminum alloy thin steel plate to improve the corrosion resistance of its steel plate.

Raw material: Pickling hot rolled strip,cold rolled carbon structure steel, high quality carbon structure steel and low alloy steel coil should match standard: GB708-88: Dimension, figuration, weight and allowed deviation of cold rolled sheets/strips and GB13237-91: Quality carbon structural steel cold rolled thick sheets/strips

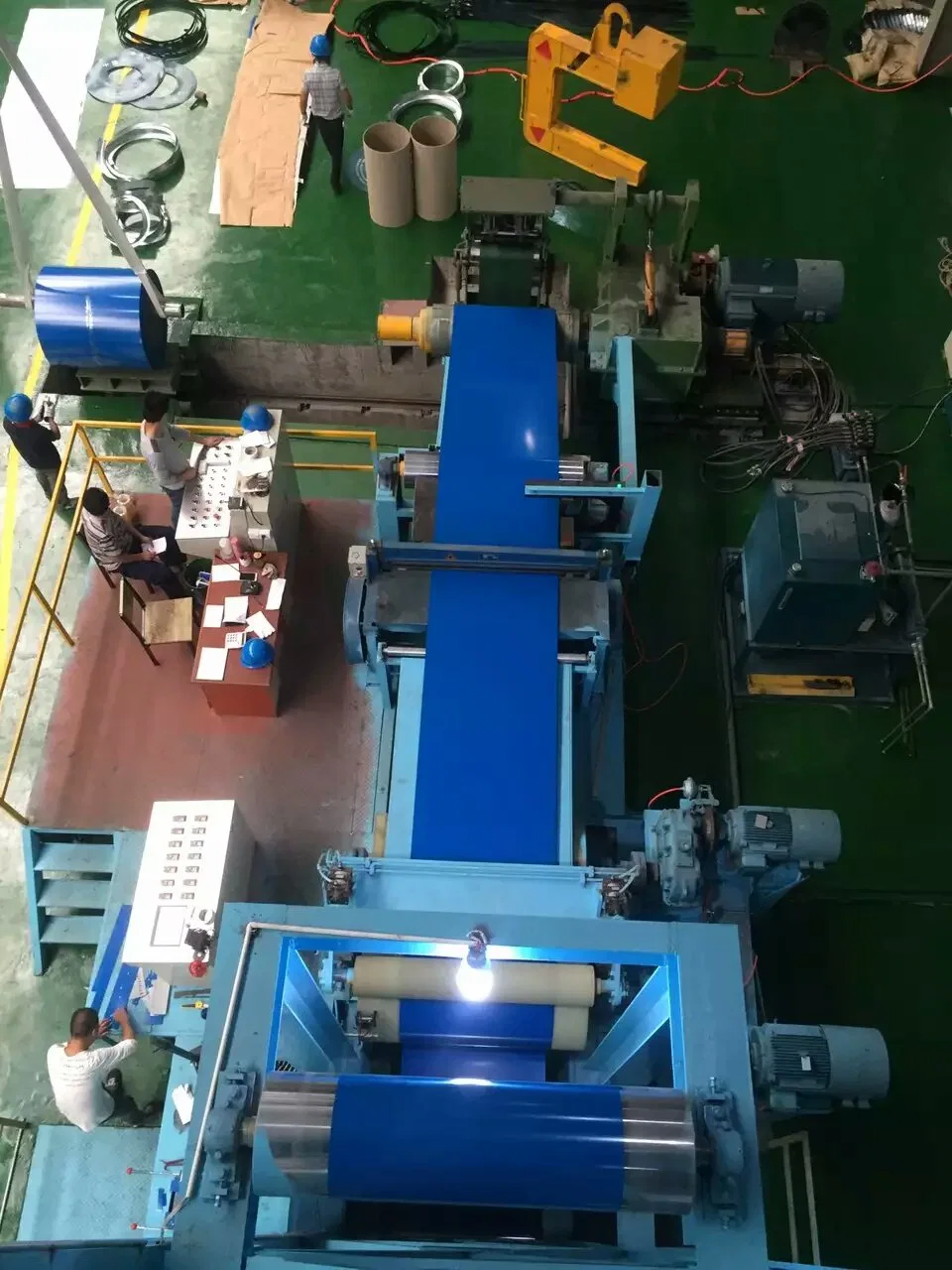

The hot dip galvanized steel sheet to be cleaned will be immersed in the dissolved zinc pot after reduction annealing to make the surface adhere to a layer of zinc or zinc-aluminum alloy thin steel sheet to improve the corrosion resistance of the steel sheet.Hot dip galvanized steel is mainly used in construction, home appliances, automobiles, machinery, electronics, light industry and other industries.

Line Main Properties :

Line Main Properties : 1. Line Type : horizontal, vertical, combination of vertical and horizontal

2. Specification / Thickness : cold rolled strip / min. 0.12mm, max. 2.5mm

hot rolled strip / min. 1.5mm, max. 5mm

Width : min. 550mm, max. 1500mm

3. Speed in Process Section: max. 200m/min (240m/min for GL)

4. Continuous Annealing Furnace:

Furnace Type: horizontal, vertical, combination of vertical and horizontal (L type) Heating Method: Gas non-oxidation heating (NOF), Gas radiant tube heating (RTF), Electric radiant tube and electric resistance tape heating Cooling Method: Shielding gas regular air jet cooling, rich hydrogen high speed air jet cooling

5. Zinc pot: jet flow ceramic induction zinc pot (GL line with pre-melting pot)

6. Air knife: single injection advanced air knife, multi-cavity air knife

7. Skin Pass Mill: 300T-800T, 4-roll wet skin pass

8. Energy saving method: high efficiency radiant tube combustion air heat exchanger, fume duct combustion air heat exchanger, fume duct hot air and hot water heat exchanger, hot shielding gas recycle injection pre- heating strip, fume heat radiant before non-oxidation heating pre-heating strip, light fiber furnace lining

Seller shall provide the production process of the typical product in the load test, and be responsible for the installation of technical guidance and service, and responsible for the commissioning.

Seller shall provide the production process of the typical product in the load test, and be responsible for the installation of technical guidance and service, and responsible for the commissioning. Our factroy is a company specializing in metallurgical complete sets of equipment, metal plate deep processing complete sets of equipment, metal surface coating complete sets of equipment and other engineering projects, focusing on metallurgical equipment research and manufacturing for 19 years, and the national major design institutes to maintain academic exchanges and project cooperation.