Basic Info.

Product Description

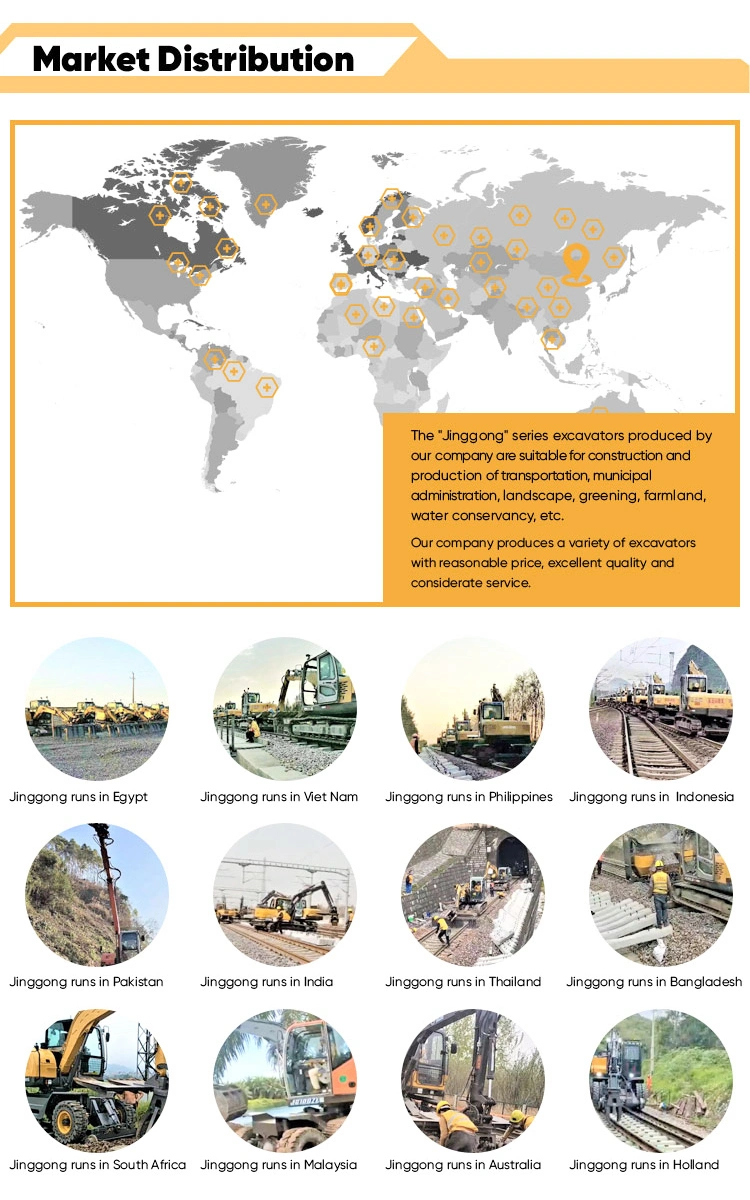

We are Quanzhou Jingli Engineering And Machinery Co., Ltd.,one of the professional excavator manufacturers in China, with 20 years of excavator manufacturing experience.

Our company mainly produces wheeld excavator, crawler excavator, grapple excavator, railway machine, sugarcane combine harvester.

Our company mainly produces wheeld excavator, crawler excavator, grapple excavator, railway machine, sugarcane combine harvester.

The structure is novel, the operation is simple, the sleeper replacement operation efficiency is high, the construction safety is high, and the practicability is stronger. Railroad sleepers are mainly replaced manually. Since the sleepers are made of reinforced concrete, the weight is as high as 400-500 kg. Manual sleeper replacement will have high labor intensity, low operating efficiency, and low construction safety. The problem. After adopting the new railway sleeper replacement machine, the operating efficiency reaches 40-50 sleepers/hour, which can reach 20 manual workers, greatly reducing the labor management cost and improving the operation safety.

8 tons chain excavator with sleeper changer max grabing weight 0.5 ~ 0.6 tons

This small crawler excavator is specially designed for the replacement of railway sleepers. The average Each pillow changing machine can replace 1.5 pillows per minute, which greatly reduces the labor management cost and improves the operation safety.

Length*width*height | 6100*2800*2650mm |

| Rated Power | 48KW |

Machine weight | 8000KG |

1. It has a compact structure, atmospheric appearance, stylish and beautiful appearance, more youthful vitality, light operation and good coordination.

2.Jingong Railway sleeper-changing machine is short and sophisticated, the scope of application of the venue is wider, the transfer is more convenient, the operation is simple, and the cost performance is high.

3.The operating efficiency after using the Jingong railway pillow replacement machine can reach 20 manual workers.

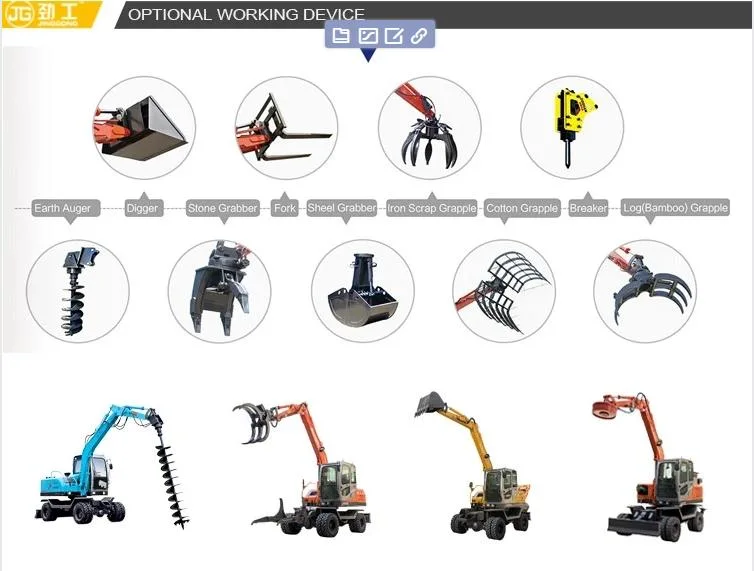

4.The grab can be customized according to the actual width of your local sleepers.We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.

1.Strict quality management produce effective and stable products to meet customers' needs.

2. Strict detecting system and advanced inspection equipment.

3.Professional sales team, quality inspection & report, maritime logistics guidance.

4.We grants our clients a twelve-month-period or 2000-hours warranty for any machine purchased from us.

5.We offer perfect facilities and comfortable environment and can provide training services to different users.