Basic Info.

Model NO.

YD-CIP

Customized

Customized

Material

Stainless Steel 304/316

Control

PLC Automatic

Factory

Yes

Auto Mode

Fully Automatic

Transport Package

Plywood Case

Specification

Customized

Trademark

YODEE

Origin

China

HS Code

8419899090

Production Capacity

200set Per Months

Product Description

100L 300L CIP Unit Brewery CIP System Clean in Place System Stainless Steel Tanks

CIP cleaning system ( CIP ) is commonly known as clean-in-place system. It is widely used in food and beverage production enterprises with high mechanization, such as beverages, dairy products, fruit juices, fruit pulp, jams, and wines.

The CIP cleaning system mainly refers to the equipment (tanks, pipes, pumps, filters, etc.) and the entire production line, without manual disassembly or opening. In a predetermined period of time, the cleaning liquid of a certain temperature is sprayed and circulated on the surface of the equipment through a closed pipeline flow rate to achieve the purpose of cleaning.

Detail

1. It can save the consumption of cleaning agent, water and steam;

2. Increase the service life of machine parts;

3. Reduce the harmfulness of labor force and acid-base in the operation, and avoid affecting the cleaning effect due to the difference in the mental state of the operator;

4. The system can perform pickling, alkali washing, hot water washing and other processes independently, and can also program specific cleaning programs for fully automatic cleaning according to needs;

5. It can not only effectively clean and dry the equipment, but also control the growth of microorganisms; at the same time, manual control and semi-automatic control systems can be configured according to customer requirements.

CIP Classification

1) According to the number of configured storage tanks, it is divided into: one tank, two tanks, three tanks, four tanks, etc.

2) According to different control methods, it can be divided into: manual control, semi-automatic control, fully automatic configuration and other methods.

3) According to the number of cleaning circuits, it is divided into: 1-way, 2-way, 3-way, and 4-way.

Feature

1. Stable CIP cleaning, using man-machine interface image display.

2. Automatic switching of various process parameters, automatic adjustment of cleaning time, PH, temperature and other parameters.

3. There are two modes of operation: manual control or automatic control.

4. All operations can be recorded, which is convenient for GMP certification.

5. The CIP cleaning system has single tank, double tank and multiple tanks for users to choose, and there are mobile and fixed types.

Cleaning Time Reference

1. Water washing: 10-20 minutes, temperature: 40-50ºC.

2. Alkali washing cycle: 20-30 minutes, temperature: 60-80ºC.

3. Intermediate water washing cycle: 10 minutes, temperature: 40-50ºC.

4. Pickling cycle: 10-20 minutes, temperature: 60-80ºC.

5. Final water washing with pure water: 15 minutes, temperature: 40-50ºC.

NOTICE: For the configuration of the CIP system, and the detailed configuration and equipment, please contact the professionals of the YODEE team to select the CIP system according to different conditions to be cleaned.

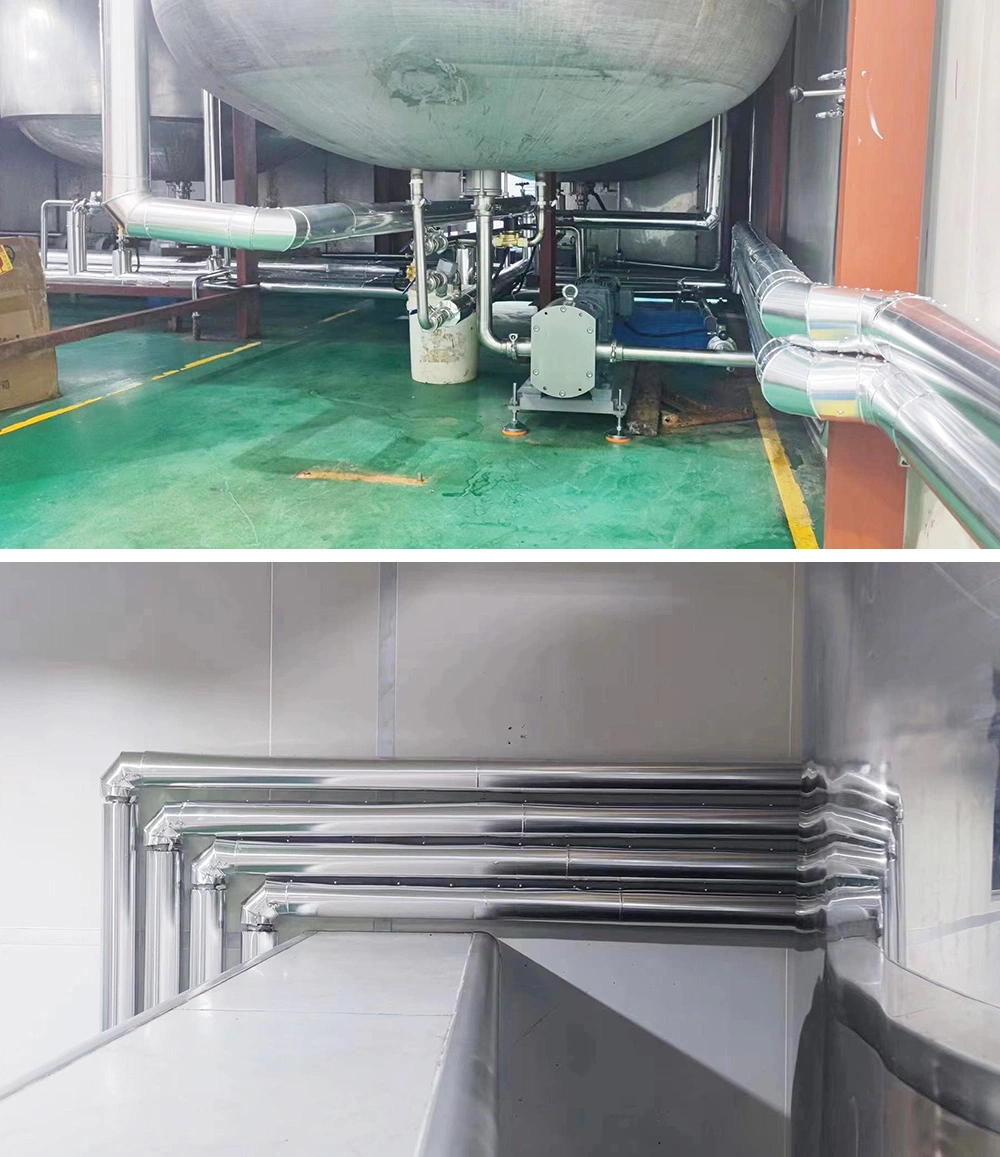

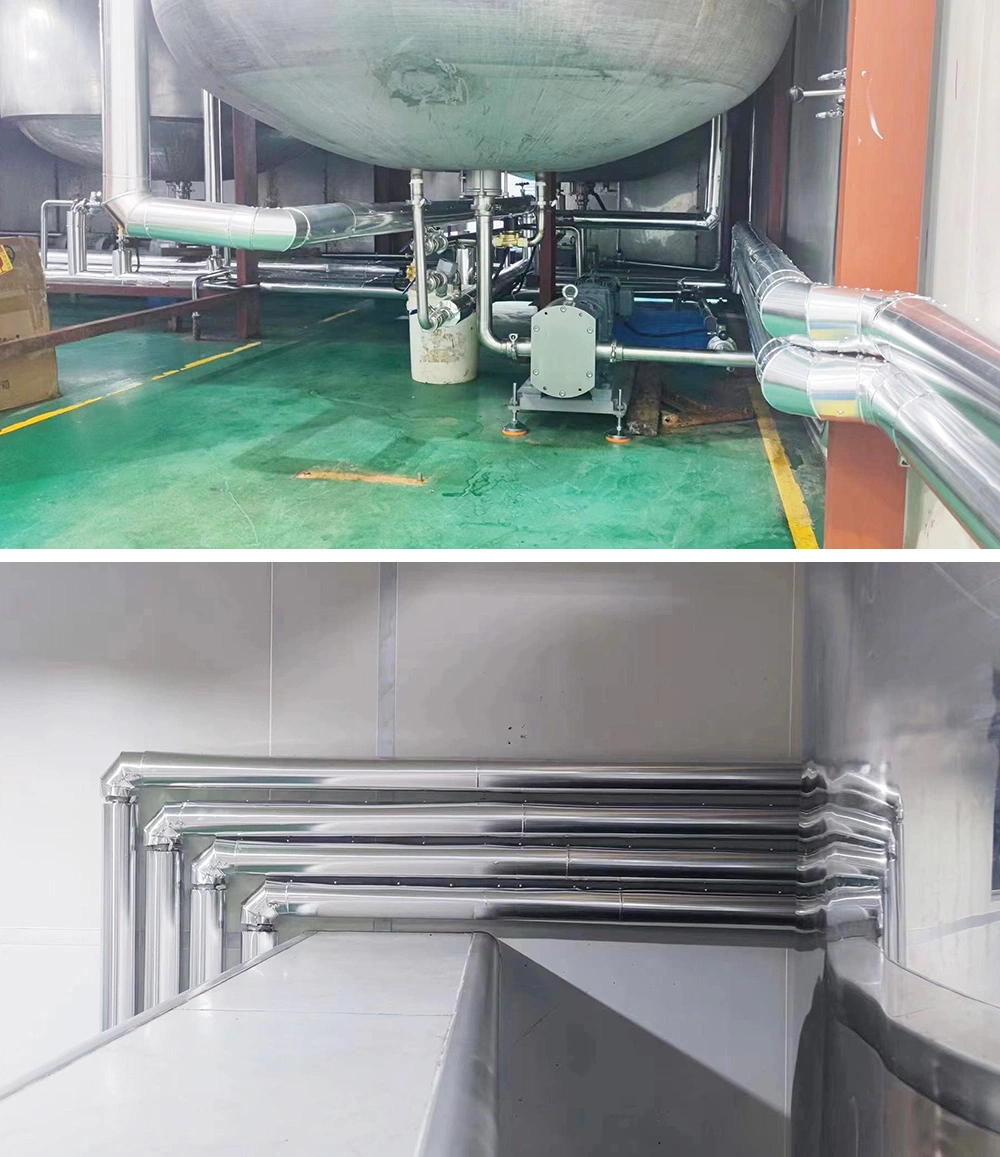

Engineering Case

About Yodee

After-sale Service

1. YODEE products will provide a one-year machine warranty service, and accessories will be replaced free of charge.

2. YODEE will provide lifelong machine technical support and technical support services for the later transformation of the old factory.

3. YODEE will provide engineers to guide the installation of equipment and equipment maintenance training services at the customer's factory if necessary.

4. YODEE can accept customer engineers to Chinese factories for equipment training.

Shipment Service

1. If you have a transportation agent, you can directly arrange to come to our company to pick up the goods.

2. If you do not have a transportation agent yet, YODEE will provide you with different ways of machine transportation services (sea, air, express, rail transportation) according to different situations for choice.

3. Under special circumstances, if the machine exceeds the shipping size of the container, YODEE will still plan and provide you with the best shipping plan for you to choose.

CIP cleaning system ( CIP ) is commonly known as clean-in-place system. It is widely used in food and beverage production enterprises with high mechanization, such as beverages, dairy products, fruit juices, fruit pulp, jams, and wines.

The CIP cleaning system mainly refers to the equipment (tanks, pipes, pumps, filters, etc.) and the entire production line, without manual disassembly or opening. In a predetermined period of time, the cleaning liquid of a certain temperature is sprayed and circulated on the surface of the equipment through a closed pipeline flow rate to achieve the purpose of cleaning.

Detail

1. It can save the consumption of cleaning agent, water and steam;

2. Increase the service life of machine parts;

3. Reduce the harmfulness of labor force and acid-base in the operation, and avoid affecting the cleaning effect due to the difference in the mental state of the operator;

4. The system can perform pickling, alkali washing, hot water washing and other processes independently, and can also program specific cleaning programs for fully automatic cleaning according to needs;

5. It can not only effectively clean and dry the equipment, but also control the growth of microorganisms; at the same time, manual control and semi-automatic control systems can be configured according to customer requirements.

CIP Classification

1) According to the number of configured storage tanks, it is divided into: one tank, two tanks, three tanks, four tanks, etc.

2) According to different control methods, it can be divided into: manual control, semi-automatic control, fully automatic configuration and other methods.

3) According to the number of cleaning circuits, it is divided into: 1-way, 2-way, 3-way, and 4-way.

Feature

1. Stable CIP cleaning, using man-machine interface image display.

2. Automatic switching of various process parameters, automatic adjustment of cleaning time, PH, temperature and other parameters.

3. There are two modes of operation: manual control or automatic control.

4. All operations can be recorded, which is convenient for GMP certification.

5. The CIP cleaning system has single tank, double tank and multiple tanks for users to choose, and there are mobile and fixed types.

Cleaning Time Reference

1. Water washing: 10-20 minutes, temperature: 40-50ºC.

2. Alkali washing cycle: 20-30 minutes, temperature: 60-80ºC.

3. Intermediate water washing cycle: 10 minutes, temperature: 40-50ºC.

4. Pickling cycle: 10-20 minutes, temperature: 60-80ºC.

5. Final water washing with pure water: 15 minutes, temperature: 40-50ºC.

NOTICE: For the configuration of the CIP system, and the detailed configuration and equipment, please contact the professionals of the YODEE team to select the CIP system according to different conditions to be cleaned.

Engineering Case

About Yodee

After-sale Service

1. YODEE products will provide a one-year machine warranty service, and accessories will be replaced free of charge.

2. YODEE will provide lifelong machine technical support and technical support services for the later transformation of the old factory.

3. YODEE will provide engineers to guide the installation of equipment and equipment maintenance training services at the customer's factory if necessary.

4. YODEE can accept customer engineers to Chinese factories for equipment training.

Shipment Service

1. If you have a transportation agent, you can directly arrange to come to our company to pick up the goods.

2. If you do not have a transportation agent yet, YODEE will provide you with different ways of machine transportation services (sea, air, express, rail transportation) according to different situations for choice.

3. Under special circumstances, if the machine exceeds the shipping size of the container, YODEE will still plan and provide you with the best shipping plan for you to choose.