Basic Info.

Model NO.

SJSZ65/132

Customized

Customized

Condition

New

After-sales Service

Our Engineer Go UR There for Installation

Pipe Material

PVC PP PE

Voltage

380V 50Hz; 220V 60Hz

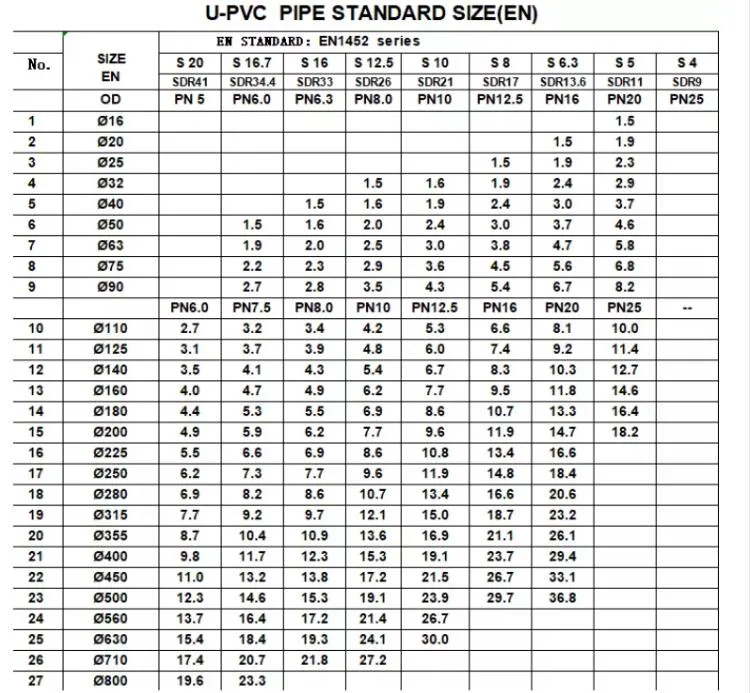

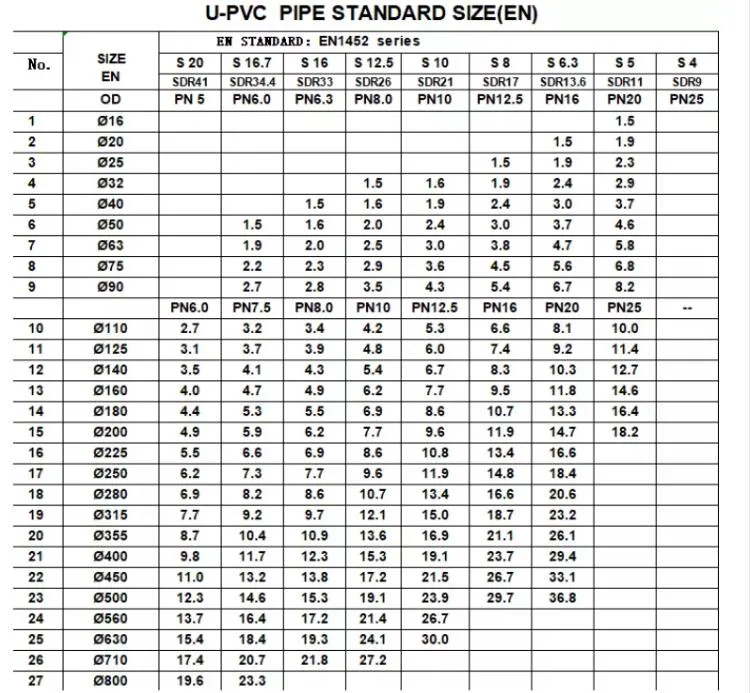

Diameter

16mm-800mm

Screw Design

Double-Screw

Type

Plastic Pipe Extruder PP/PE/PPR

Processing Type

Pipe Extrusion Machine

Keywords

PP/PE/PPR Pipe Extruder Line

Function

Pipe Making

Name1

Water Pipe Extrusion Line

Name2

PVC Drain-Pipe Production Line

Name3

PVC Pipe Making Machine

Name4

PVC Pipe Machine

Name5

Pipe Extrusion Machine

Name6

PVC Pipe Extrusion Machine

Name7

PVC Pipe Production Line

Transport Package

Plastic Film or Wooden Case

Trademark

GeGao

Origin

China

HS Code

8477209000

Production Capacity

30 Sets/Month

Product Description

63mm-125mm Water Pipe Extrusion Line Plastic PVC Drain-Pipe Production Line Strong PVC Pipe Making Machine

- PVC Plastic pipe making machine is mainly used in the production of Agricultural water supply & water discharge systems, architectural water supply & discharge systems, wire laying systems, etc. purposes.

- The unit consists of a Conical (Parallel) double screw extruder-PVC pipe mold-Vacuum forming tank-Haul-off machine-Cutting machine-Stacker/Belling machine.

- the line can be equipped with a Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.

- Process Flow: Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mould → Vacuum Calibration Tank → Four claws Haul-off → Planetary Saw Cutter → Belling machine/ Tripping Table → Final Product Inspecting &Packing

Product Paramenters

Technical Parameters of Main Extruder

Product Details:

Conical double-screw extruder

PVC pipe extrusion mould

Vacuum calibration tank

Pipe Haul-off Machines

Pipe Cutter

Pipe Stacker

Final product

Packing&Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

Our Services :

Our after sales service teamwork is very strictly on quality.our machine will be checked very carefully on every

steps,Meanwhile,we send our engineer to install equipment on client.

Company Introduction

Our company occupies an area of 20,000 square meters, and we own 7,000-square-meter international standard factory building.

Ourcompany is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, conedouble -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

FAQ

Q:Are you machinery factory or trading company?

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days

- PVC Plastic pipe making machine is mainly used in the production of Agricultural water supply & water discharge systems, architectural water supply & discharge systems, wire laying systems, etc. purposes.

- The unit consists of a Conical (Parallel) double screw extruder-PVC pipe mold-Vacuum forming tank-Haul-off machine-Cutting machine-Stacker/Belling machine.

- the line can be equipped with a Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.

- Process Flow: Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mould → Vacuum Calibration Tank → Four claws Haul-off → Planetary Saw Cutter → Belling machine/ Tripping Table → Final Product Inspecting &Packing

Product Paramenters

| NO. | Name | Quantities |

| 1 | Screw loader | 1set |

| 2 | SJSZ xxxx Conical twin-screw extruder | 1set |

| 3 | Mould | 1set |

| 4 | Vacuum cooling tank | 1set |

| 5 | Haul-off | 1set |

| 6 | Cutting machine | 1set |

| 7 | Stacker/Auxiliary equipment | 1set |

| Auxiliary equipment | ||

| 8 | Mixing machine | 1set |

| 9 | Crusher machine | 1set |

| 10 | Belling machine | 1set |

| 11 | Pulverizer machine | 1set |

| 12 | Printer machine | 1set |

Technical Parameters of Main Extruder

| Pipe Diameter | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ110/220 | ||||||||||

| Main extruder | 16-63 | 32-110 | 63-200 | 16-32 | 20-63 | 63-110 | 63-110 | 110-250 | 200-400 | 200-400 | 315-630 | 315-630 | 400-1000 | |

| Die Head | Double outlet | Single outlet | Single outlet | Four outlet | Double outlet | Single outlet | Double outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet |

| Down-Stream equipment | GRF63 | GRF63 | GRF110 | GRF200 | FGF63 | SGF63 | GF110 | SGF110 | GF250 | GF400 | GF400 | GF630 | GF630 | GF1000 |

| Total Power | 81kw | 85kw | 86.5kw | 91kw | 85kw | 85kw | 136kw | 103kw | 114kw | 131kw | 212kw | 220kw | 270kw | 500kw |

Product Details:

Conical double-screw extruder

| Feeding system | Motor Power | 1.5kw |

| Force Feeder Motor Timing | ABB inverter | |

| Screw | Diameter of screw | 80/156mm |

| Material of screw | 38CrMoAl | |

| Barrel | Material | 38CrMoAlA |

| Heating mode | Cast aluminum + stainless steel covering | |

| Method of cooling: | air blow |

PVC pipe extrusion mould

| Material | Made by 40Cr. Inner surface polished |

| Pipe Thickness Control | With 2 different pipe wall thickness |

| Calibration mould material | Wearable tin bronze ZQSn5-2-5 |

Vacuum calibration tank

| Dimensions | Length: 6000mm |

| Vacuum pump | Hydroseal vacuum pump Power: 2.2kw x2 |

| Water pump | Power: 3KW x 2 |

| Tank material | Stainless steel, Limit switch; Electric cabinet with water-proof protection |

Pipe Haul-off Machines

| Haul-off length | 1000mm |

| Haul-off Motor Power | 0.55KW×4sets |

| Haul-off Speed | 1.1KW×2sets Inverter |

| Haul-off Speed | 0.5~12 meters/min |

Pipe Cutter

| Cutting pipe diameter scope | 16~40mm |

| Saw blade Diameter: | 230mm |

| Cutter motor power: | 0.75KW×2 sets |

| Blade Bracket Longitudinal Moving Distance | 500mm |

Pipe Stacker

| The length of stacker | 2 meters |

| Support-Board | 0.8mm stainless steel board |

| Working Method | pneumatic, with stroke switch soleplate, to provide the fixed length cutting signal |

Packing&Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

Our Services :

Our after sales service teamwork is very strictly on quality.our machine will be checked very carefully on every

steps,Meanwhile,we send our engineer to install equipment on client.

Company Introduction

Our company occupies an area of 20,000 square meters, and we own 7,000-square-meter international standard factory building.

Ourcompany is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, conedouble -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

FAQ

Q:Are you machinery factory or trading company?

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days