Basic Info.

Packaging Material

Plastic

Product Name

Turbine Heat Circulation Shrink Tunnel

After-Sales Service Provided

Overseas Third-Party Support Available

Shrink Film

PE/POF/PVC/OPP

Feature

Turbine Heat Circulation

Sealing Speed

up to 30m/Min

Keyword

Lower Heat Lost

Specification

2200x1000x1230 mm

Trademark

JHG

Origin

China

Product Description

Product Description

T-Series Turbine Heat Circulation Shrink Tunnel

Cost Saving and Environmental Protection Heat Shrink Tunnel.

Earth Conservation with Spending Less Money.

Earth Conservation with Spending Less Money.

T-Series shrink tunnel produces consistent uniform film shrink using heavy-duty, variable speed blowers and heating elements. This combination creates a recirculating air system that forces air to all package surfaces. Independent control systems regulate

temperature, air velocity and conveyor speeds. The efficient heating system on each machine reduces the amount of electricity and the cost of operation.

temperature, air velocity and conveyor speeds. The efficient heating system on each machine reduces the amount of electricity and the cost of operation.

Features

• Turbine heat circulation system design with great reduce heating time.

• Lower heat lost than traditional shrink tunnel.

• Diminish the use of electricity.

• Independent control systems regulate temperature, air velocity, flow directions and conveyor speeds.

• The lateral air flow and bottom air flow strength can be manipulated.

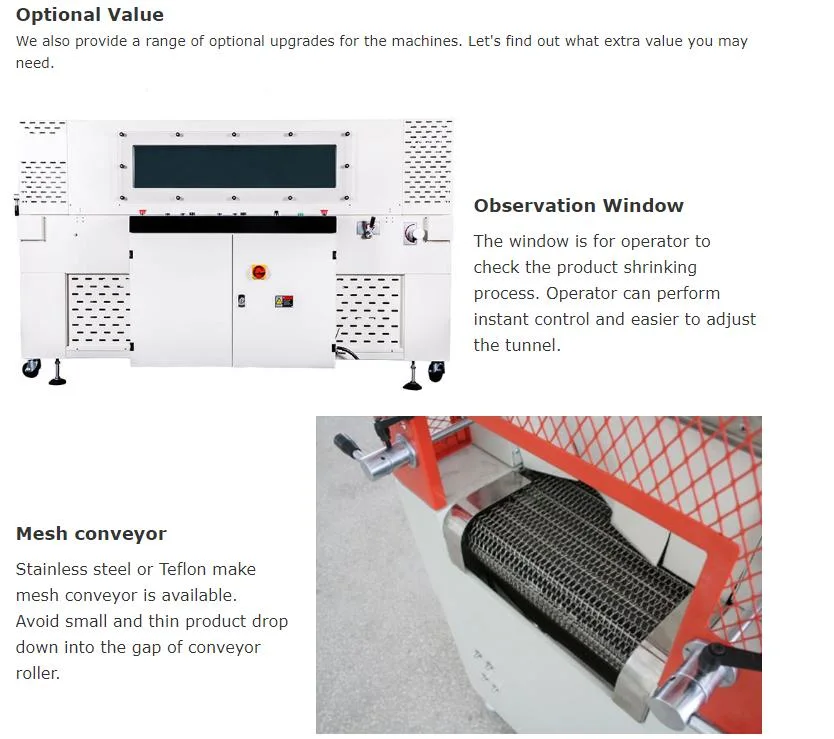

• Different conveyor systems are available (live roller, stainless steel, modular plastic or Teflon mesh).

• Lower heat lost than traditional shrink tunnel.

• Diminish the use of electricity.

• Independent control systems regulate temperature, air velocity, flow directions and conveyor speeds.

• The lateral air flow and bottom air flow strength can be manipulated.

• Different conveyor systems are available (live roller, stainless steel, modular plastic or Teflon mesh).

Specification

| Model | T-61 | T-62 | T-63 |

| Machine Szie LxWxH(mm) | 1450×895×1080 | 1700×940×1160 | 2200×1100×1230 |

| Chamber Size LxWxH(mm) | 1100×300×200 | 1200×350×280 | 1700×440×350 |

| Maximum Packing Size WxH(mm) | 280×150(W×H) | 300×230(W×H) | 400×300(W×H) |

| Power | 380V, 3P, 10.5Kw | 380V, 3P, 14.5Kw | 380V, 3P, 19Kw |

| Operating Power Consumption(V) | 5 | ||

| Conveyor Speed (m/min) | 0~30 | ||

| Model | T-64 | T-65 | T-66 |

| Machine Szie LxWxH(mm) | 2200×1142×1230 | 2200×1300×1230 | 2400×1660×1160 |

| Chamber Size LxWxH(mm) | 1700×540×350 | 1700×700×350 | 1900×1200×280 |

| Maximum Packing Size WxH(mm) | 500×300(W×H) | 650×300(W×H) | 1050×230(W×H) |

| Power | 380V, 3P, 21Kw | 380V, 3P, 24Kw | 380V, 3P, 28Kw |

| Operating Power Consumption(V) | 5 | ||

| Conveyor Speed (m/min) | 0~30 | ||