Basic Info.

Model NO.

KQ Series

Application

Milk, Yogurt, Ice Cream

Customized

Customized

Name

Stainless Steel Half Open Lids Heating Mixing Pre

Capacity

100--2000L

Material

Sanitary Stainless Steel 304/316/316L

Cooling

Ice Water /Cooling Water

Delivery

10 Days After Get Your Advance Payment .

Surface

Polished and Mirror

Mixer

Mixer / Mixer with Scraper /Stirrer with Paddle

Voltage

Follow Your Request

Market

All Country

Orign

Shanghai China

Motor

ABB / Siemens /China Brand

Working Life

More Than 10 Years

Packing

Wooden Box

MOQ

1set

Insulation Wall

Polyurethane Foam /Rock Wool

Transport Package

Wooden Box

Specification

Based on special order

Trademark

KAIQUAN

Origin

China

HS Code

8434200000

Production Capacity

50000PC Per Year

Product Description

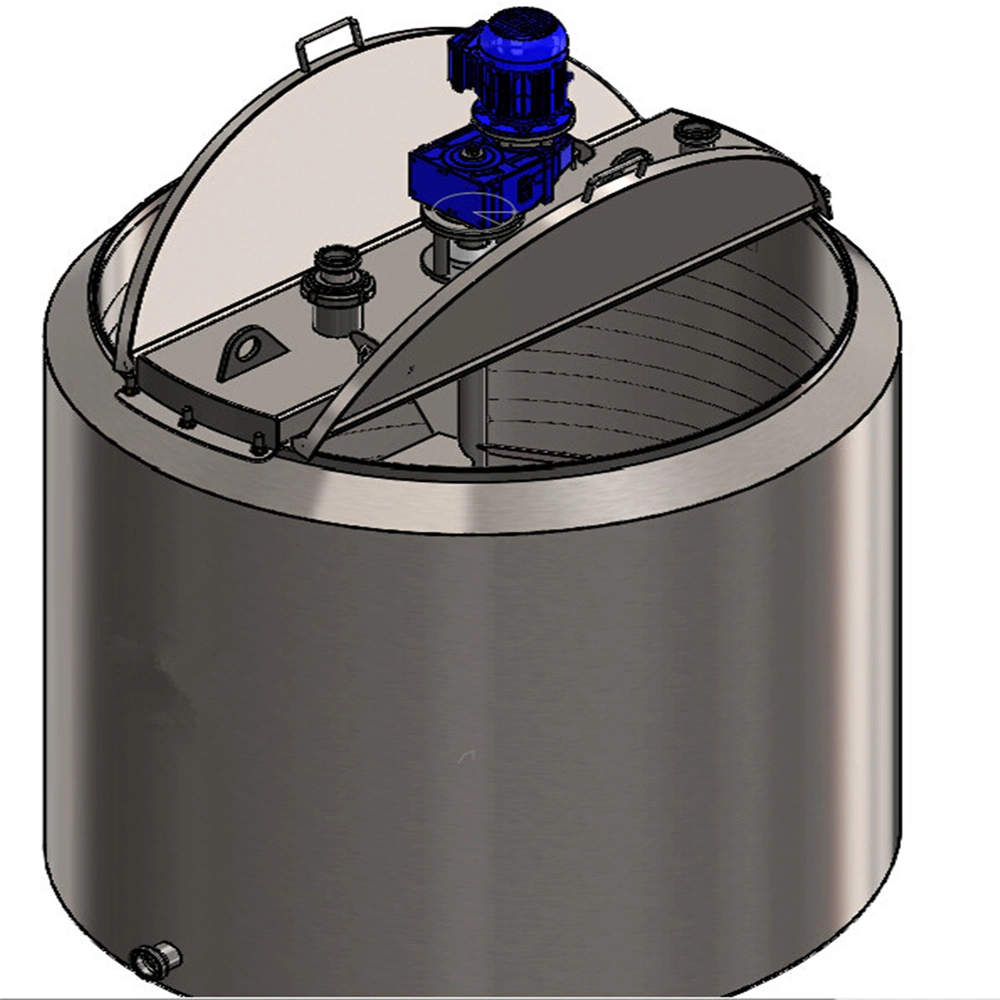

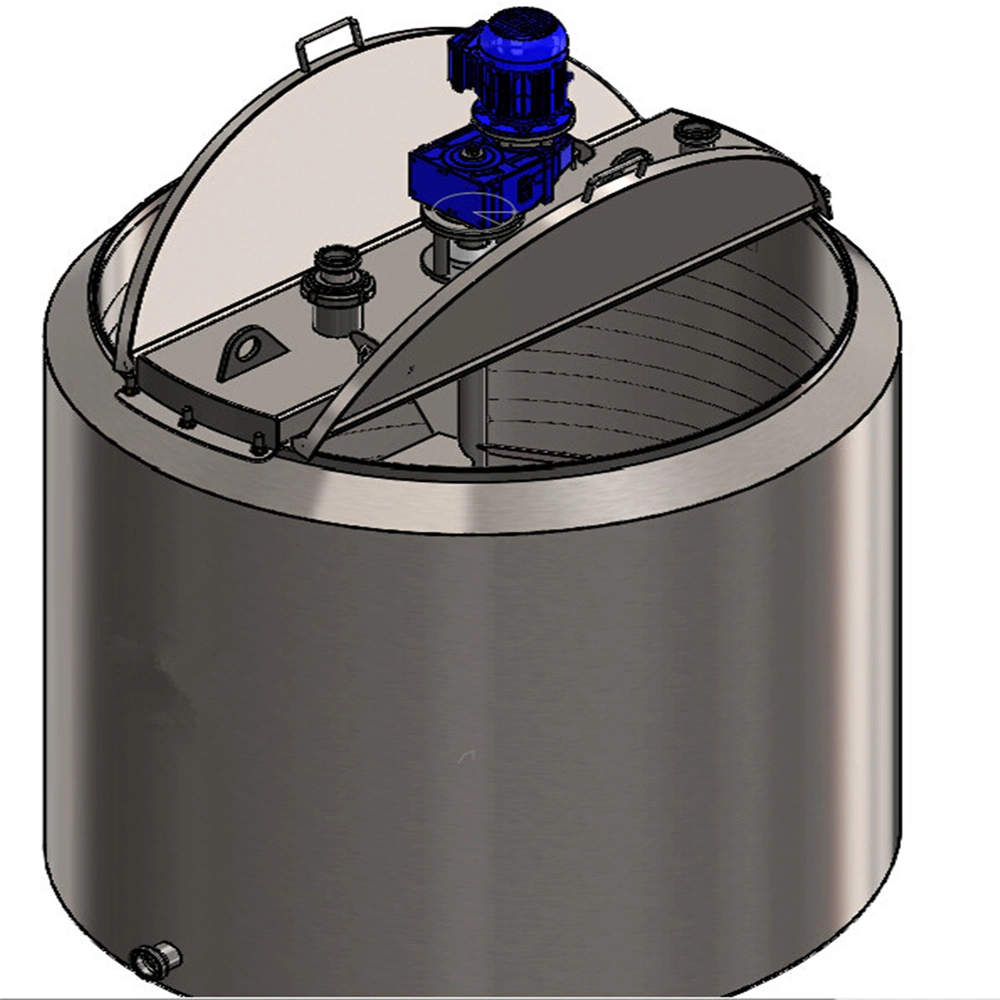

Stainless Steel Half Open Lids Heating Mixing Pressure Tank Factory

Classification of Urn

According to Structure: Opening on the head & ramp bottom, opening on the head & conical sealed head on the bottom

According to Structure: Opening on the head & ramp bottom, opening on the head & conical sealed head on the bottom

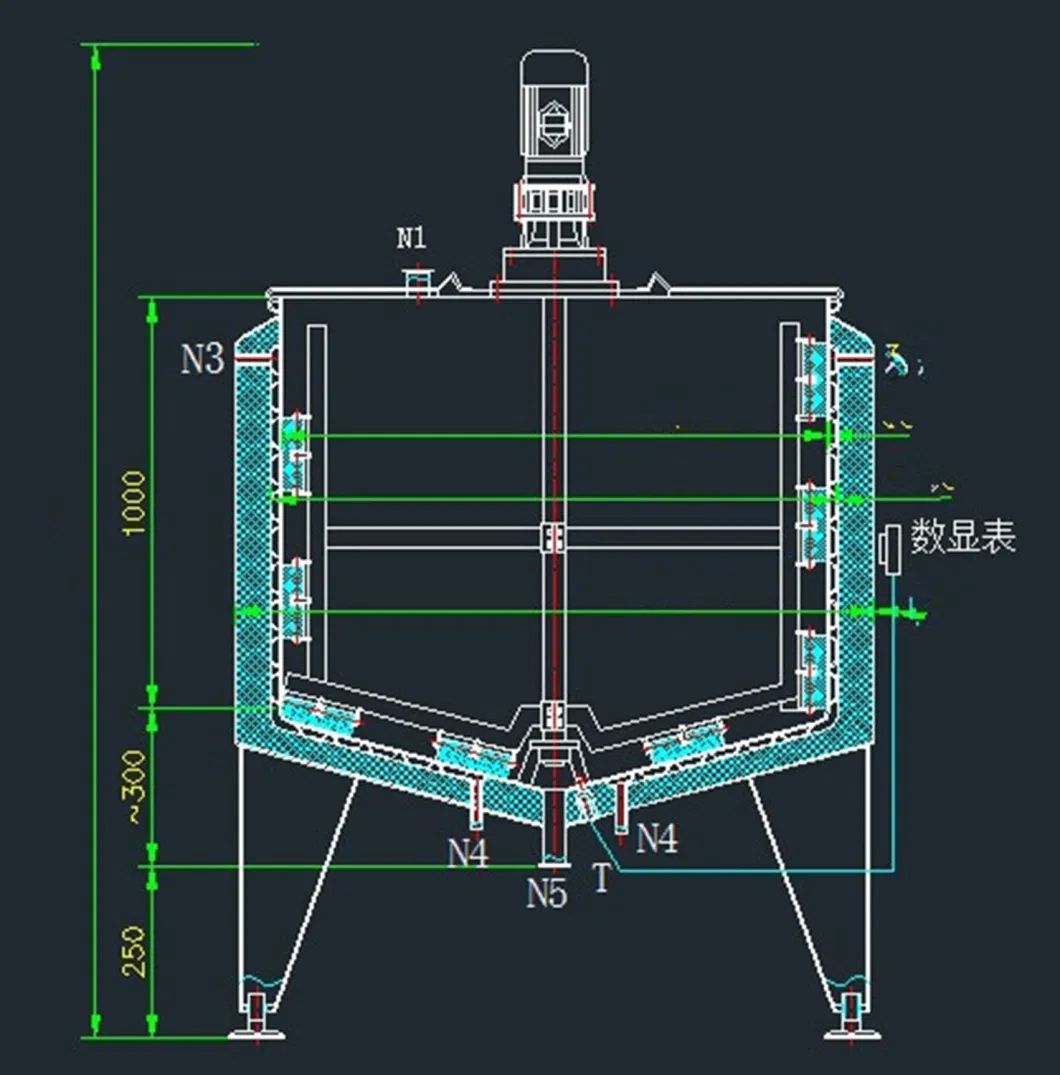

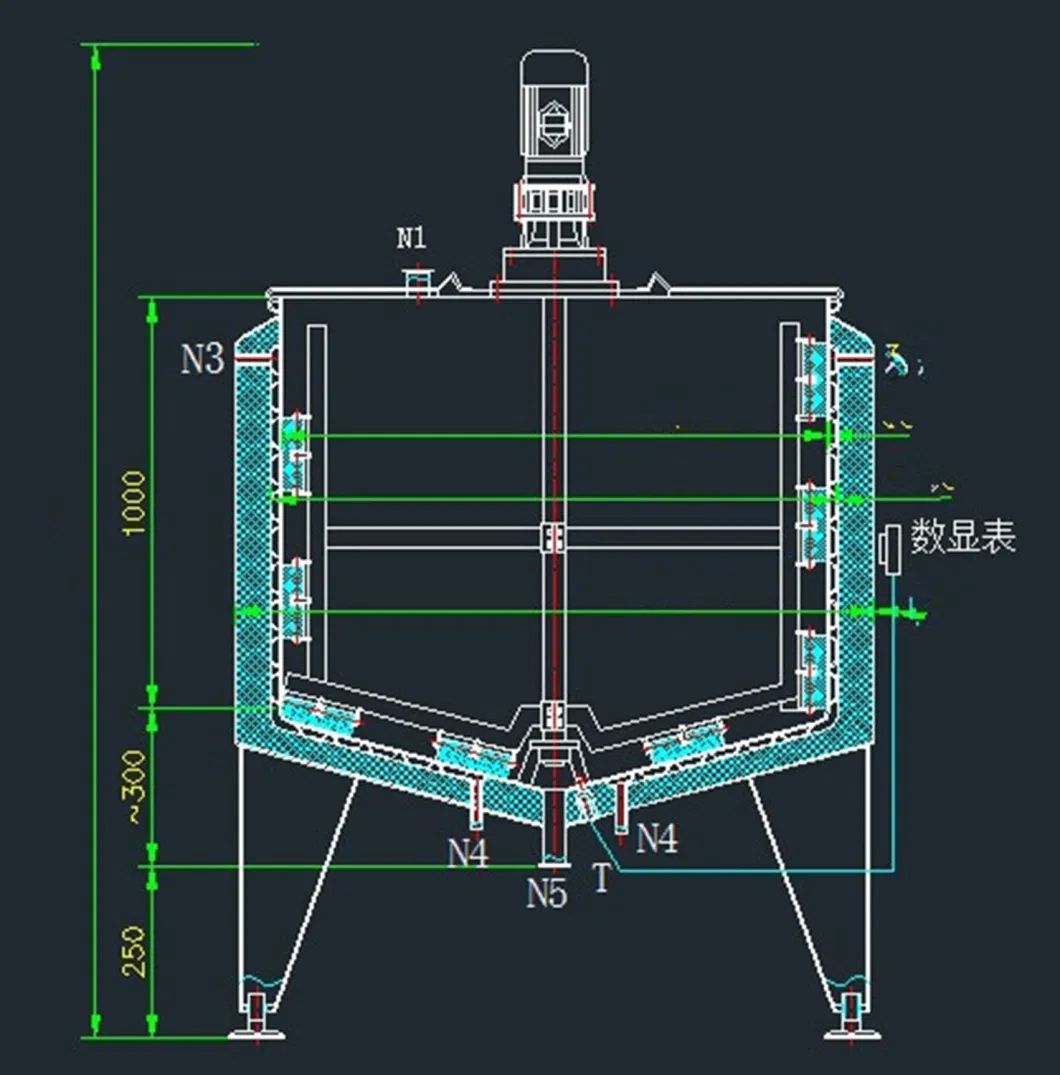

Structure of Urn

Structure: The interior, jacket, insulation layer, the outer foreskin, speed reducer, agitator, thermometer and so on.

The interior: Stainless steel SUS304, mirror-polished surface.

Jacket: The A3 or 1Cr18Ni9Ti steel plate, strengthen circle spiral device, the cold water from bottom to top (without pressure), to achieve the best heating and cooling purposes.

Insulation group: Stainless steel plate cast into scales, insulation layer use polyurethane or mineral wool to keep the temperature, achieve insulation effect.

Speed reducer: Cycloid planetary reducer, fixed in the tray of the beam, a shaft gear wheel connect with the impeller flexibly for easy removal and cleaning.

Thermometer: Specification 100C-1000C, installed on the beam, straight out to minimum medium position, makes sure that can indicate temperature even when the liquid material to the lowest position, to achieve sterilization and aging purposes.

Stainless Steel Half Open Lids Heating Mixing Pressure Tank Factory .

Classification of Urn

| Volume | 300L | 400L | 500L | 600L | 800L | 1000L | 1500L | 2000L | 3000L | |

| Body diameter(mm) | Φ 800 | Φ 800 | Φ 900 | Φ 1000 | Φ 1000 | Φ 1000 | Φ 1200 | Φ 1300 | Φ 1600 | |

| Body height(mm) | 600 | 800 | 800 | 800 | 1000 | 1220 | 1220 | 1500 | 1500 | |

| Motor power(kw) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 1.5 | 2.2 | 3 | |

| Stirring speed(rpm) | 36r/min | |||||||||

| Working pressure | ≤ 0.09Mpa | |||||||||

| Working temperature | < 100° C | |||||||||

| Accessories | Thermometer, safety valve, pressure gauge | |||||||||

According to Structure: Opening on the head & ramp bottom, opening on the head & conical sealed head on the bottom

According to Structure: Opening on the head & ramp bottom, opening on the head & conical sealed head on the bottom Structure of Urn

Structure: The interior, jacket, insulation layer, the outer foreskin, speed reducer, agitator, thermometer and so on.

The interior: Stainless steel SUS304, mirror-polished surface.

Jacket: The A3 or 1Cr18Ni9Ti steel plate, strengthen circle spiral device, the cold water from bottom to top (without pressure), to achieve the best heating and cooling purposes.

Insulation group: Stainless steel plate cast into scales, insulation layer use polyurethane or mineral wool to keep the temperature, achieve insulation effect.

Speed reducer: Cycloid planetary reducer, fixed in the tray of the beam, a shaft gear wheel connect with the impeller flexibly for easy removal and cleaning.

Thermometer: Specification 100C-1000C, installed on the beam, straight out to minimum medium position, makes sure that can indicate temperature even when the liquid material to the lowest position, to achieve sterilization and aging purposes.

Stainless Steel Half Open Lids Heating Mixing Pressure Tank Factory .