Basic Info.

Product Description

Hydraulic Tank Jacking Device is designed for lifting of storage tank with top-to-bottom construction method, which is innovated by NAEC using advanced modular design concept.

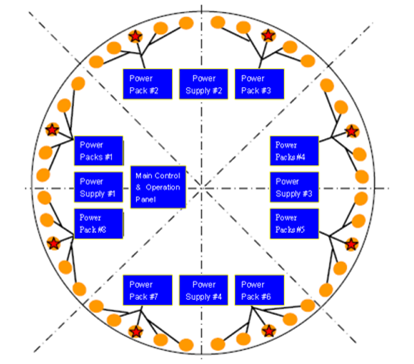

Compared with conventional type lifting system, NAEC Hydraulic Lifting System is modular design, each modular contains one power pack with 5 cylinder jacks. Cylinder is double tele type, also has adjustable stay. Pls see below picture(Yellow round means cylinders, Blue square means power supplies and main control).

Hydraulic Tank Jacking Device has bellow features:

- Standard oil cylinder stroke is 2800mm, all work is done in the first shell height. It is very safe.

- Unique design, more suitable for application of automatic welding machine. It matches with our specialized top-to-bottom girth welding machine to realize automatic welding of inside girth seam.

- The lifting efficiency is high. For example, if shell height is 2.6m, it takes 15-20mins to lift the shell to the proper position.

- Synchronism controlling is PLC supervised, if the hydraulic lifting system lifts not synchronized, it can be adjusted manually to ensure synchronism. In this way, the whole system will works very safely.

- It can keep continuous lifting. Continuous lifting capability improves tank construction efficiency.

- Modularized design ensures all jacks invested can work for different diameter tank, greatly reduce any possible waste.

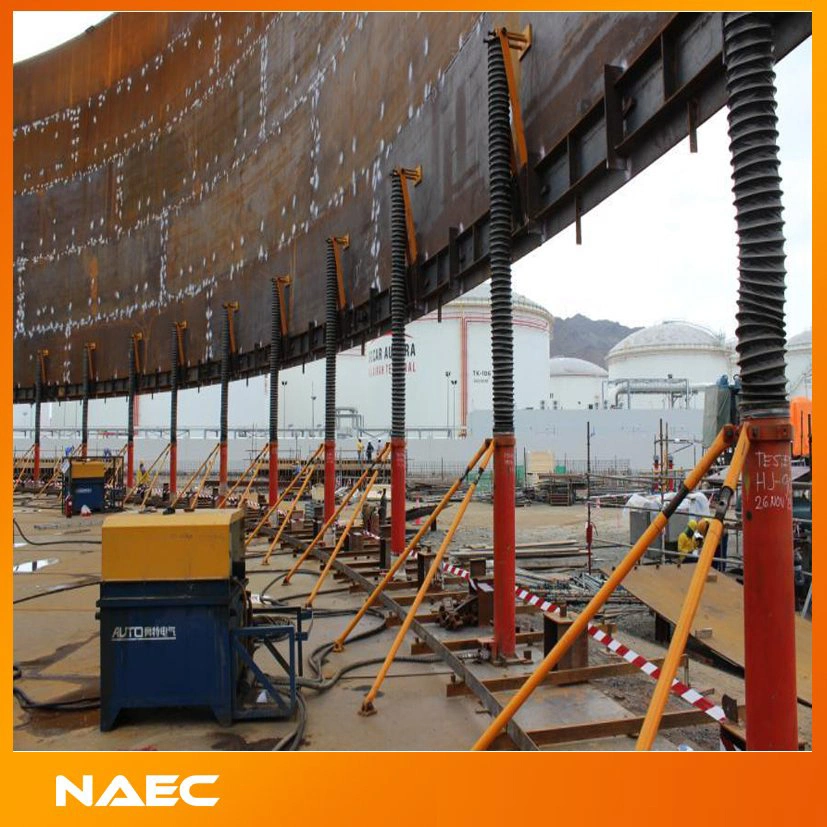

By using Hydraulic Tank Jacking Device, the lifting safety can be ensured, lifting efficiency is improved, and lifting operation is easier. NAEC hydraulic lifting system is reliable choice for storage tank construction companies. Such hydraulic lifting system has been used in many storage tank/ tank farm construction projects. Below are some pictures on site.

Tank Construction Machines

| 1 |  | Girth Seam Welding Machine >Applicable to both bottom-to-top and top-to-bottom tank erection >Adopting Sub Arc Welding technology >Standard machine suitable for shell plate width: 1.3M-2.8M >Max. Efficiency of AGW could be 30 times as manual welding |

| 2 |  | Vertical Seam Welding Machine >Suitable for tank plate wall thickness is from 10mm to 50mm >Motor frequency inverter drive system >Weatherproof control box with digital display for welding speed >Travel speed: 0~2200mm/min >Beveled gear drive reducer, good locking ability in both directions |

| 3 |  | Butt/Corner Seam Welding Machine >Applicable to butt seam welding of bottom plates >With magnetic idler system >More than 99% Qualified first X-ray test. >Suitable for both Top-to-Bottom and Bottom-to-Top Tank Construction Method |

Welcome to visit NAEC in Nanjing, China.

Our company view

Nanjing Auto Electric Co., Ltd (NAEC) was established in 2001, taking promoting "Lean Fabrication to Global Energy Engineering Industry" as its mission, NAEC's core business is to provide Lean-fabrication One-stop Solution to energy engineering contractors and fabricators. With advanced innovation ability and continuous integration of new technology & processes, NAEC's solution ensure its users high quality and efficient fabrication, and make itself become worldwide clients' most preferred partner.

Our Strategic Clients are

EPC companies, Contractors or Fabricators in Onshore Oil & Gas Exploration, Transportation, Storage, Refinery & Chemical

EPC companies, Contractors, Fabricators or Equipment Manufacturers in Offshore Oil & Gas Exploration, Treatment, Transportation & Storage

EPC companies, Contractors or Fabricators in Nuclear Power, Wind Power, or Thermal Power

Various Energy Engineering Equipment Manufacturers

We provide Lean-fabrication One-stop Solution for Energy Engineering EPC Companies/ Contractors/ Fabricators, Based on Following Systems:

NAEC Lean-fabrication Mode

NAEC Lean-fabrication Management System

NAEC Lean-fabrication Production System

NAEC Lean-fabrication One-stop Solution can help engineering fabrication operators to solve project problems. It can organize fabrication production and ensure the final delivery in good quality and on time.