Basic Info.

Model NO.

pppl

Annual Design Production Capacity

320 Thousand Tons

Thickness

0.18-1.2mm

Width

800-1250mm

Product Weight

<10tons

Spangle

Zera/Nomal/Big/Small

Medium and Small Zinc Flower

Non-Chromated, Chromated

Technology

Reduction Method Hot DIP Galvanizing

Transport Package

Standard Seaworthy Package

Origin

China

Production Capacity

2400000

Product Description

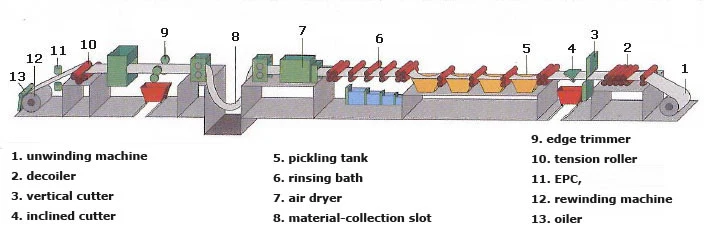

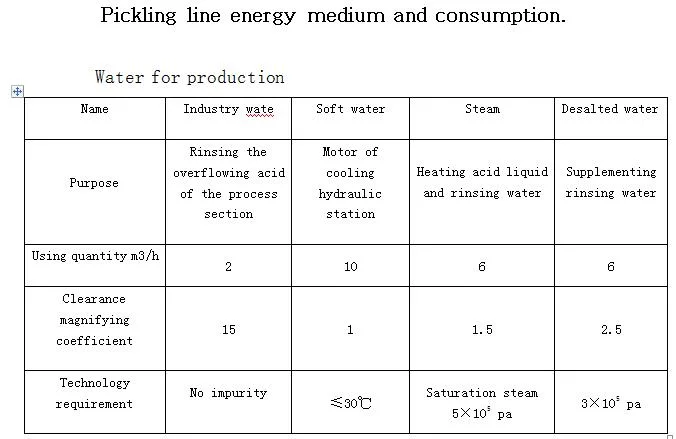

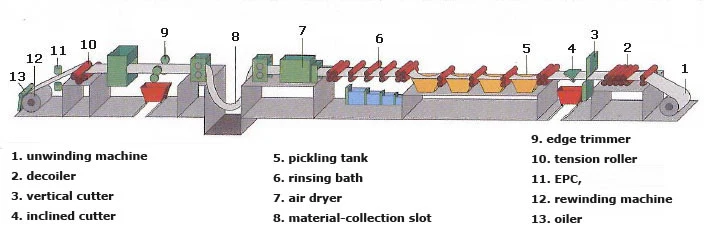

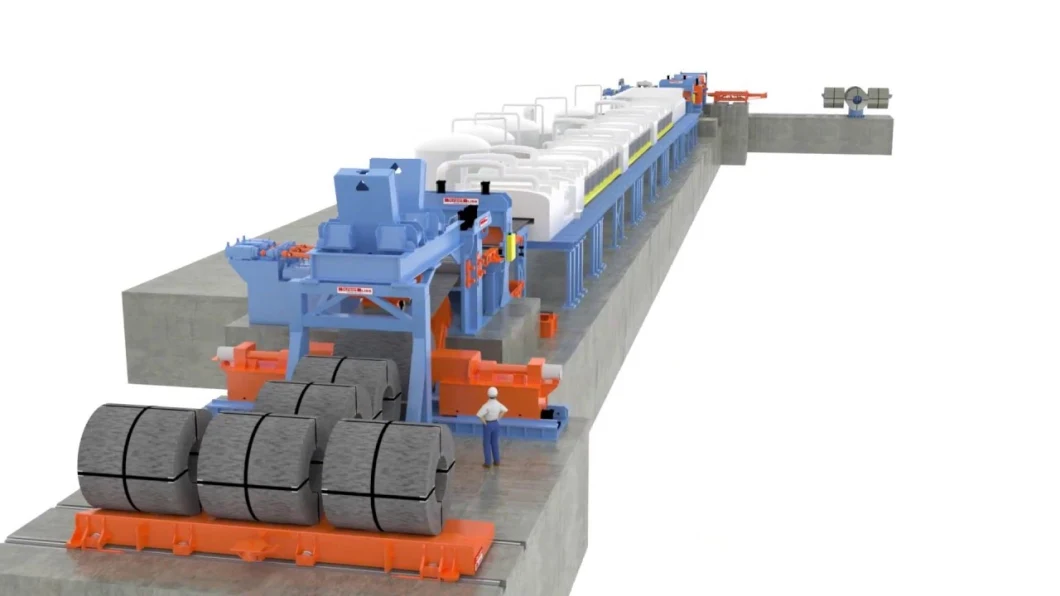

During the hot rolling process, a layer of brittle and hard oxide is formed on the surface of the steel coil. Before the cold rolling process, the oxide on the surface of the coil must be removed. This process is usually completed by the pickling unit.The pickling unit is divided into push-pull pickling production line and continuous pickling production line.

Pickling line energy medium and consumption.

Water for production

Line Main Properties:

1.Push-pull pickling adopts advanced shallow turbuleimmernt pickling process, with short pickling time and high pickling efficiency. Push-pull pickling can be divided into six sections, each section has its own outer heating and pickling system, through adjusting the temperature of every pickling sections to achieve the best pickling effect.

2.Continuous pickling adopts turbulent shallow pickling process with extinct advantages. The liquid height inside the acid tank is just 150mm, the inner and outer cover of the acid tanks, all can reduce the evaporation and improve the turbulence speed of the acid liquid.

3.Continuous pickling line has three acid tanks, each of them has separated outer heating system and acid recycled system. Through adjusting the temperature, concentration and the turbulence speed of every acid tank to achieve the best acid effect.

4.Using five-stage counter follow cascade rinse system, only need few rinsing water. Though controlling the accuracy of the conductivity in the last rinsing section to ensure the rinse quality of the strip surface.

5.Continuous pickling line has set 800t rolled skin pass mill to improve the defects of the strip shape and the quality of the strip surface, as well as eliminate part of the yield platform, and improve the product competitiveness.

6. Continuous pickling adopt reliable technical, stable running double head rotate tower side trimmer, the open degree of the shear blade, overlap amount, side seam can be adjusted automatically.

Applications

1. For constructional exterior curtain walls, aluminum composite panel.

2. Widely used in exhibition, stores, offices, banks, hotels, restaurants and apartments.

3. Decorative renovation for storey-added old buildings, facades, roofing.

4. Indoors decoration for interior walls, ceilings, bathrooms, kitchens, balconies and subway.

5. Advertisement board, display platforms, billboards and signboards.

6. Wallboard and ceilings for tunnels.

7. Raw materials in industrial purpose.

8. Material used for vehicle bodies, yachts and boat.

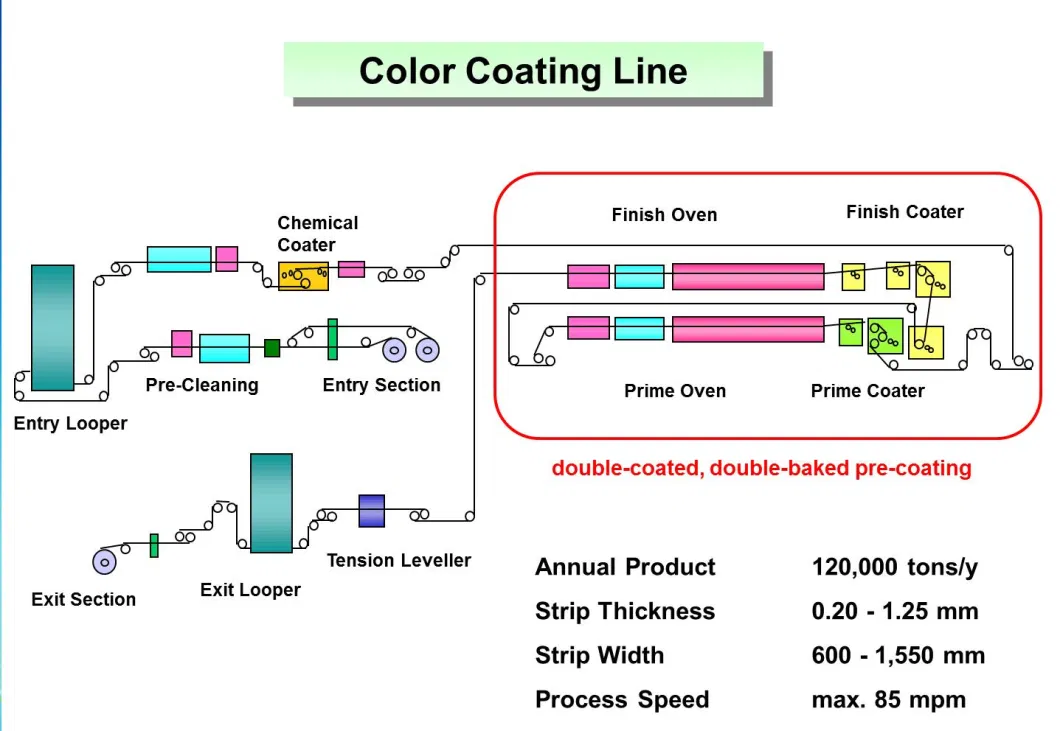

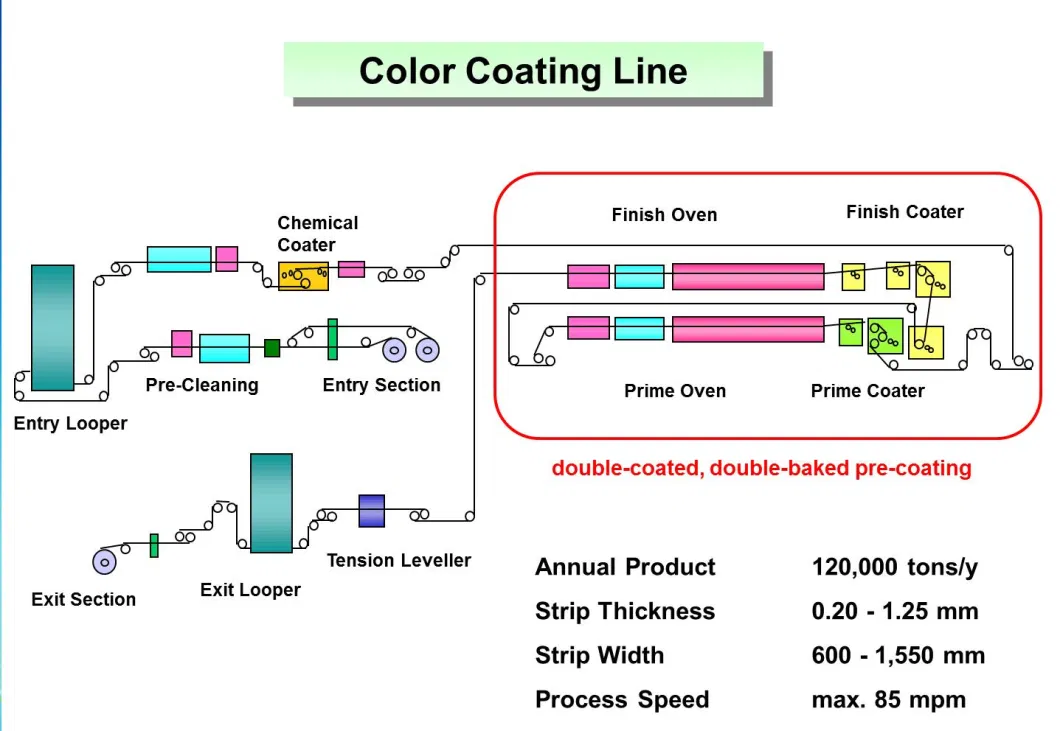

ADVANTAGES OF THE PRODUCTION LINE:

1.The production line adopts turn-back design to save the occupied area greatly.

2.The sheet belt joint adopts butt welding to effectively avoid breakage of belt

3.The dry oven adopts the temperature control equipment imported from south korea to make sure that the difference in temperature is no more than 3 degrees centigrade.

4. The two sets of coating rollers for finish coating can change with each other qucikly to ensure timely supply.

our company has one color coating line with the design specification of 0.135 to 0.8mm in thickness and width of 1000/1200, the dedigned capacity of 200,000tons/year.

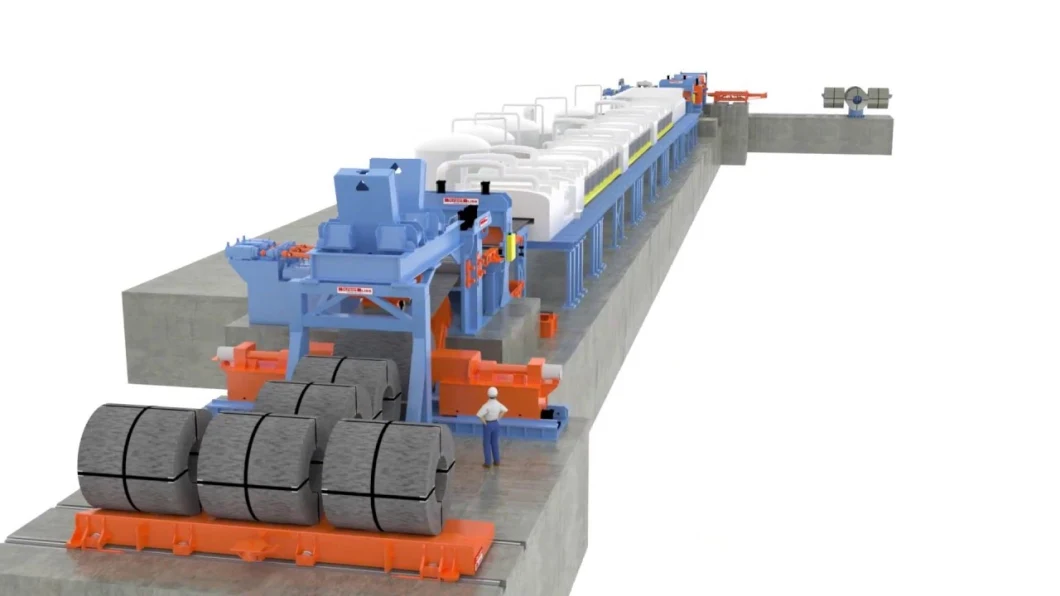

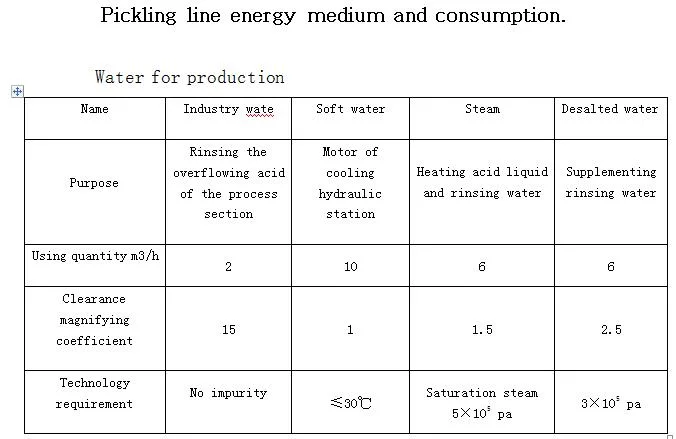

Pickling line energy medium and consumption.

Water for production

| Name | Industry wate | Soft water | Steam | Desalted water |

| Purpose | Rinsing the overflowing acid of the process section | Motor of cooling hydraulic station | Heating acid liquid and rinsing water | Supplementing rinsing water |

| Using quantity m3/h | 2 | 10 | 6 | 6 |

| Clearance magnifying coefficient | 15 | 1 | 1.5 | 2.5 |

| Technology requirement | No impurity | ≤30ºC | Saturation steam 5×105 pa | 3×105 pa |

| Product Name | pickling line |

| Material | steel |

| Energy sources | water, electricity, Nature gas |

| Strip thickness | 0.2-2.5mm |

| Strip width | 1000-1500mm (max) |

| Weight | 300--400T |

| Size | 150m*18m*20m |

| Customized | Yes |

Line Main Properties:

1.Push-pull pickling adopts advanced shallow turbuleimmernt pickling process, with short pickling time and high pickling efficiency. Push-pull pickling can be divided into six sections, each section has its own outer heating and pickling system, through adjusting the temperature of every pickling sections to achieve the best pickling effect.

2.Continuous pickling adopts turbulent shallow pickling process with extinct advantages. The liquid height inside the acid tank is just 150mm, the inner and outer cover of the acid tanks, all can reduce the evaporation and improve the turbulence speed of the acid liquid.

3.Continuous pickling line has three acid tanks, each of them has separated outer heating system and acid recycled system. Through adjusting the temperature, concentration and the turbulence speed of every acid tank to achieve the best acid effect.

4.Using five-stage counter follow cascade rinse system, only need few rinsing water. Though controlling the accuracy of the conductivity in the last rinsing section to ensure the rinse quality of the strip surface.

5.Continuous pickling line has set 800t rolled skin pass mill to improve the defects of the strip shape and the quality of the strip surface, as well as eliminate part of the yield platform, and improve the product competitiveness.

6. Continuous pickling adopt reliable technical, stable running double head rotate tower side trimmer, the open degree of the shear blade, overlap amount, side seam can be adjusted automatically.

Applications

1. For constructional exterior curtain walls, aluminum composite panel.

2. Widely used in exhibition, stores, offices, banks, hotels, restaurants and apartments.

3. Decorative renovation for storey-added old buildings, facades, roofing.

4. Indoors decoration for interior walls, ceilings, bathrooms, kitchens, balconies and subway.

5. Advertisement board, display platforms, billboards and signboards.

6. Wallboard and ceilings for tunnels.

7. Raw materials in industrial purpose.

8. Material used for vehicle bodies, yachts and boat.

ADVANTAGES OF THE PRODUCTION LINE:

1.The production line adopts turn-back design to save the occupied area greatly.

2.The sheet belt joint adopts butt welding to effectively avoid breakage of belt

3.The dry oven adopts the temperature control equipment imported from south korea to make sure that the difference in temperature is no more than 3 degrees centigrade.

4. The two sets of coating rollers for finish coating can change with each other qucikly to ensure timely supply.

our company has one color coating line with the design specification of 0.135 to 0.8mm in thickness and width of 1000/1200, the dedigned capacity of 200,000tons/year.