Basic Info.

Model NO.

HDG-SPG

Voltage

380V

Design Service

Available

Installation Service

Available

Certificate

CE ISO9001 SGS

ODM

Available

OEM

Available

Zinc Fume Enclosure

Enclosure

Pickling Room

Fully Enclosed

Pickling Tank

PP Tank with Steel Frame Outside

Application

Construction Material Zinc Coating Galvanizing

Transport Package

as Required

Specification

customized

Trademark

ANNUO

Origin

Hebei, China

HS Code

8543300000

Production Capacity

20 Sets/Year

Product Description

Traffic Signs Poles galvanizing production line

Hebei Annuo Automation Technology Co., Ltd. is a leader supplier of Hot Dip Galvanizing equipment in China, we have the following comprehensive capacities: Hot dip galvanizing line designing, manufacture, installation, commissioning and training, we also can improve the old galvanizing lines.

Black workpiece lifting equipment

Transfer Trolley transport to pickling room

Degrease, picking, rinsing and fluxing in the fully enclose room automatic control

Hot dip galvanizing

Quenching and passivation procss

Eco-friendly equpments

The whole process video monitoring and automatic control room

The whole automatic hot dip galvanizing lines consist of following parts:

- Monorail hoist

- Transfer trolley

- Chain conveyor

- Fully enclosed pre-treatment room

- PP tank

- Flux heating system

- Rinse water treatment system

- Acid fume collect and filter equipment

- Acid Neutralization system and filter press

- Furnace

- Zinc kettle

- Zinc fume enclosure

- Bag filter system for white fume

- Equipment for removing ferric iron in fluxing solution

- Zinc ash recovery furnace

Hot Dip Galvanizing Process

Advantages:

--- Lower investment and production cost

--- Short construction periods

--- Quality reliable and Durable equipment, complies with current environmental standard

--- Low maintenance and easy operation

--- High galvanizing quality

--- Advanced environment protective system

--- Flexibility designing to meet the customers' requirements

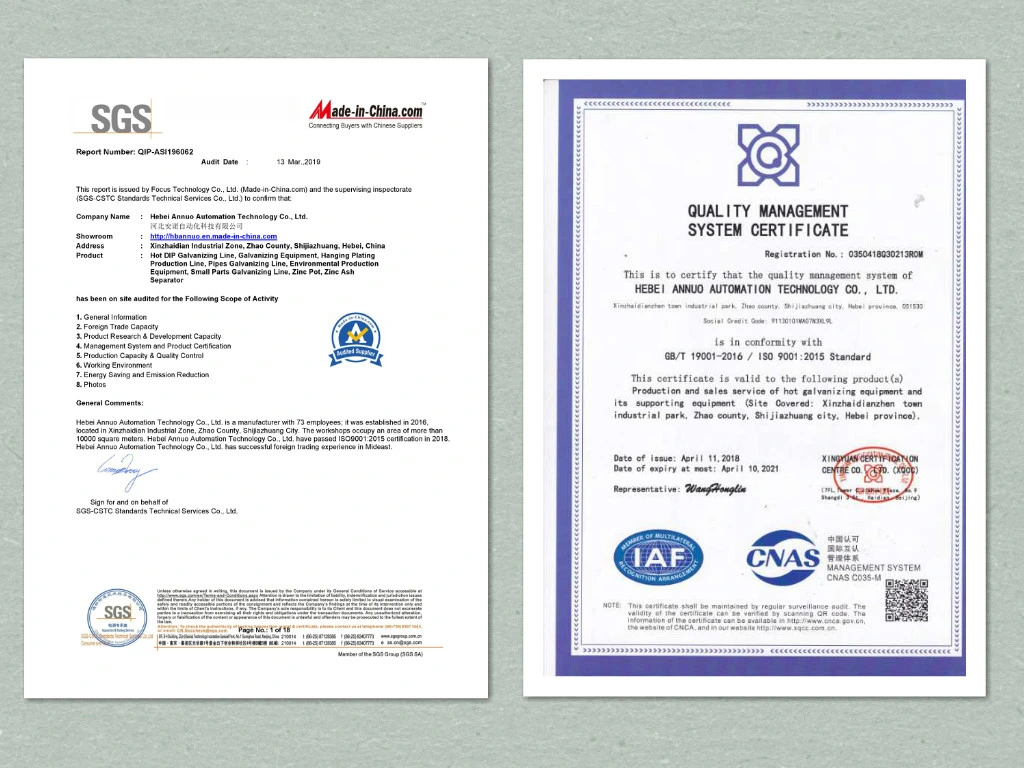

Certificates:

All products are CE Certified